Ampoule Cutting Machine - Manufacturers, Factory, Suppliers from China

All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for Ampoule Cutting Machine, Pharma Machinery Supplier, Vial Filling Machine Parts, Ampoule Sealing Machine Sop,Ampoule Closing Machine. Our intention is to assist clients understand their ambitions. We are earning wonderful attempts to realize this win-win predicament and sincerely welcome you to be a part of us. The product will supply to all over the world, such as Europe, America, Australia,Yemen, Tajikistan,Porto, Slovakia.With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we're trying our best to be your good partner.

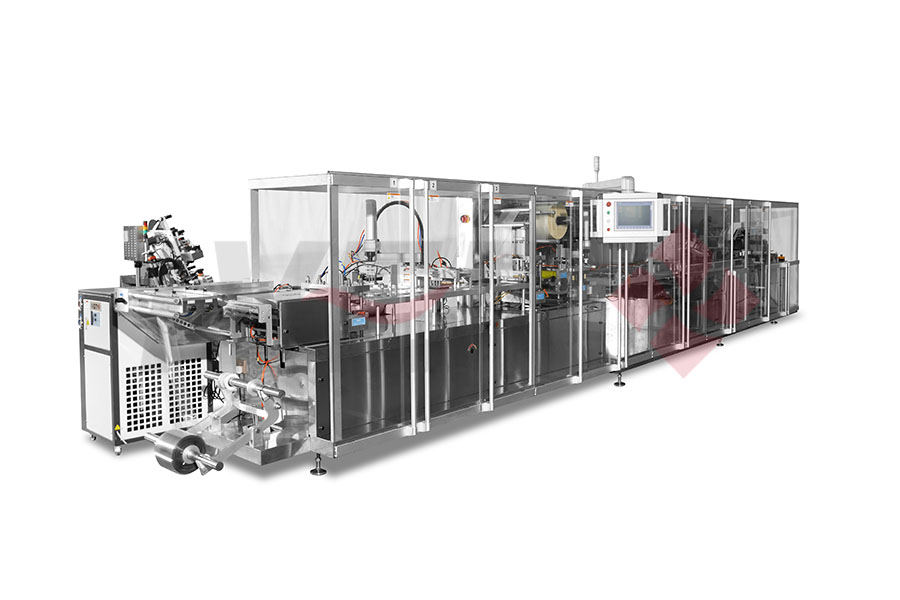

Related Products