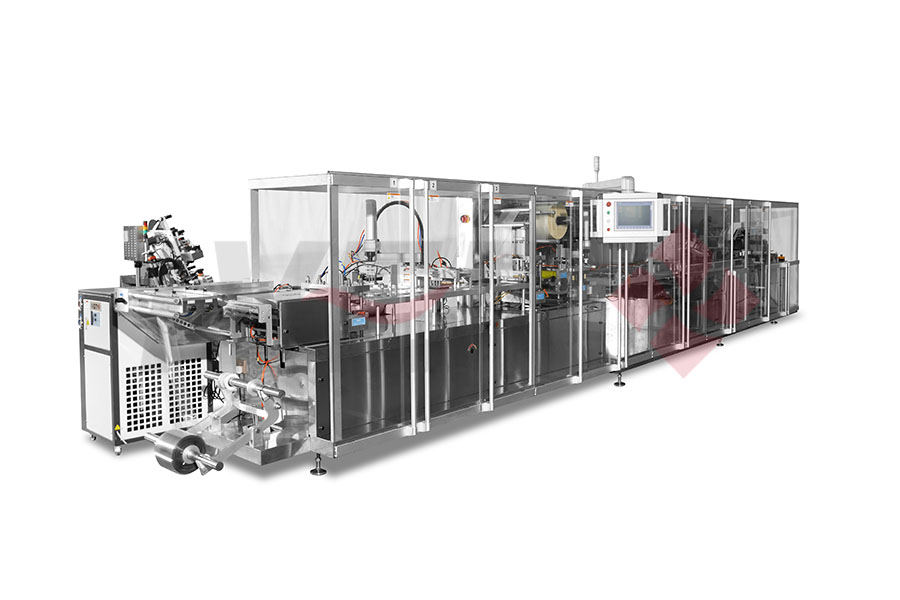

Ampoule Forming Machine - China Factory, Suppliers, Manufacturers

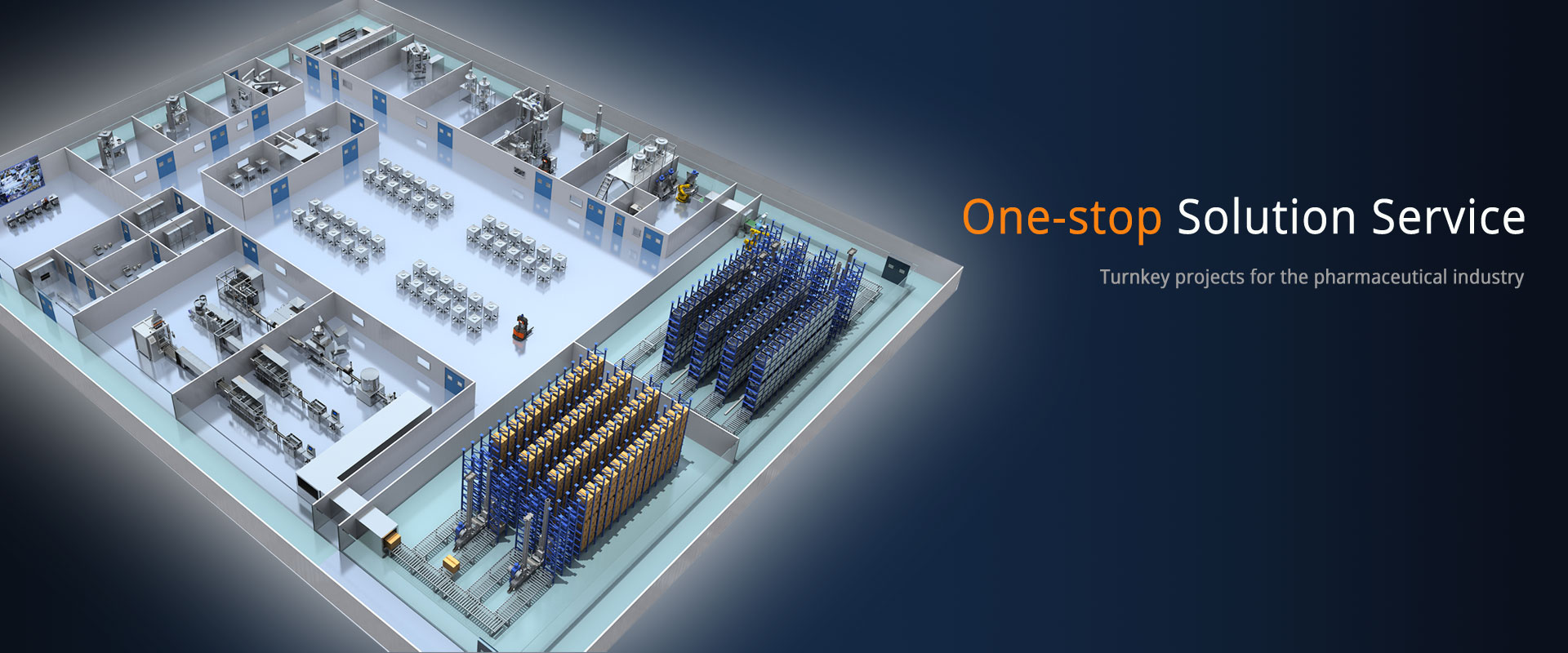

We emphasize advancement and introduce new products into the market each year for Ampoule Forming Machine, Iv Solution Manufacturer, Iv Fluid Machine, Non-Pvc Soft Bag Machinery,Injectable Vial Filling. Together with our efforts, our products have won the trust of customers and been very salable both here and abroad. The product will supply to all over the world, such as Europe, America, Australia,luzern, Leicester,Tanzania, Slovenia.We follow up the career and aspiration of our elder generation, and we are eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

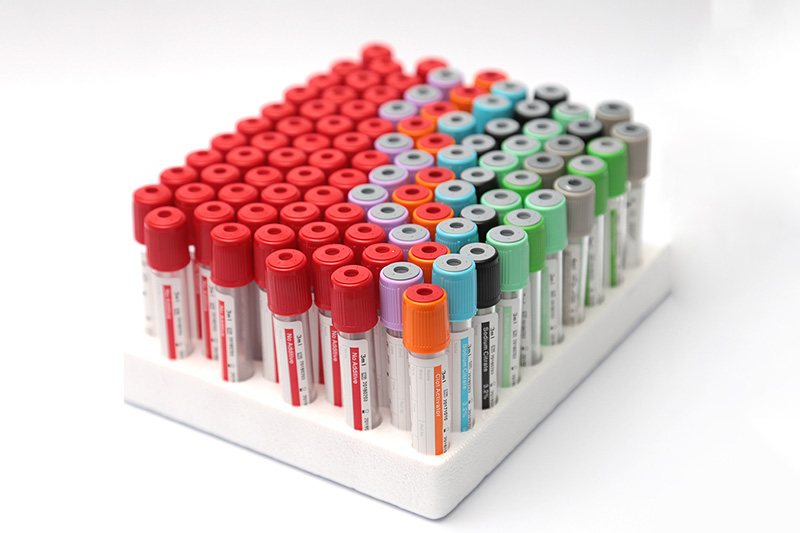

Related Products