Ampoule Washing Machine Standard Operating Procedure - China Manufacturers, Suppliers, Factory

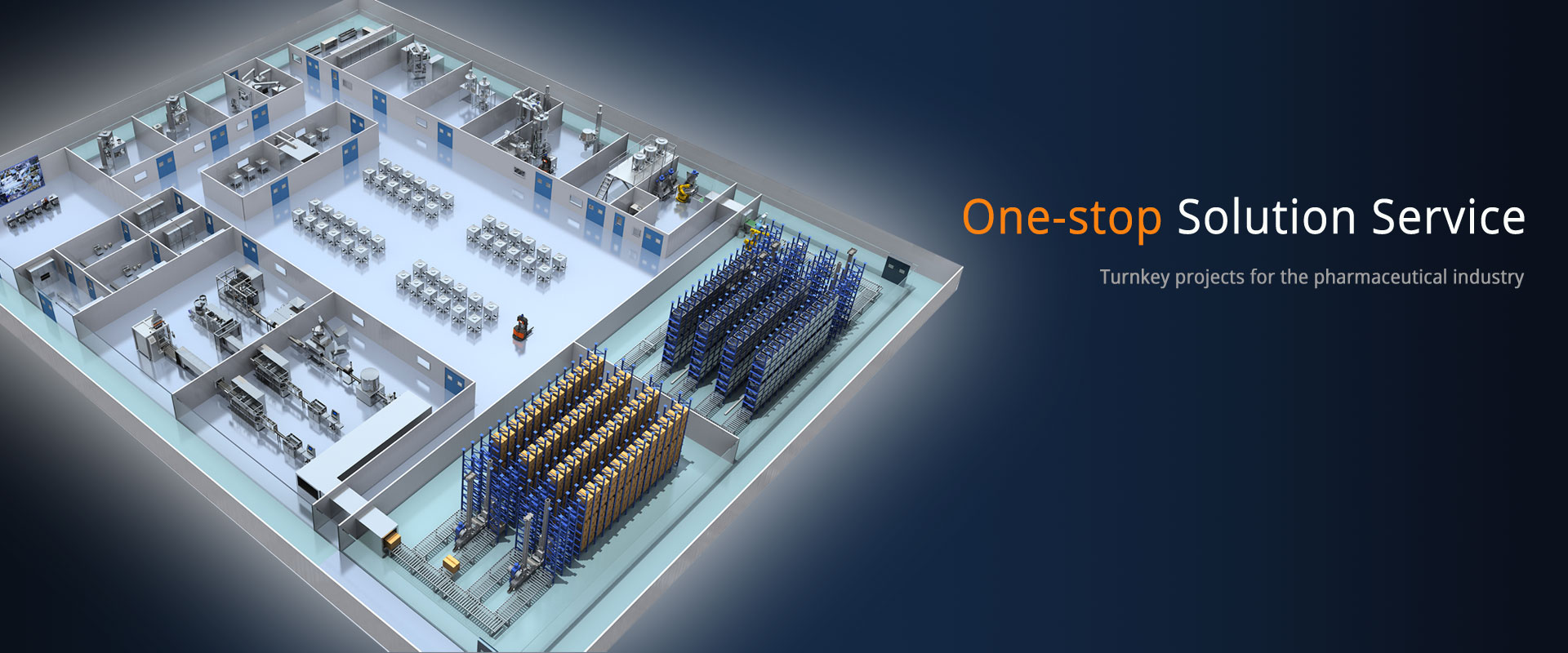

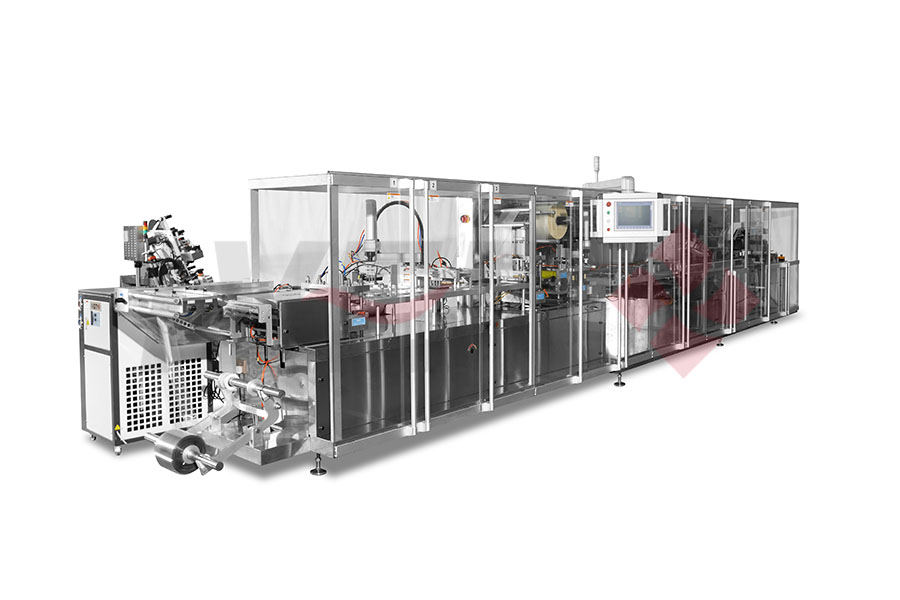

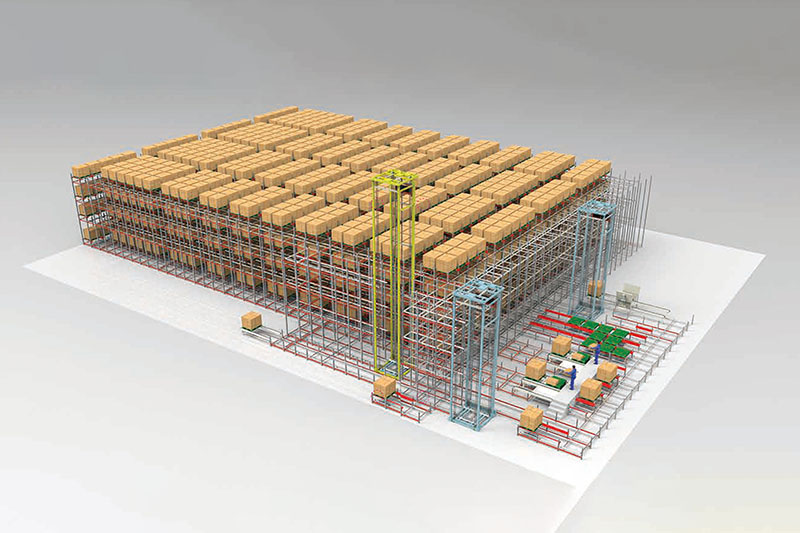

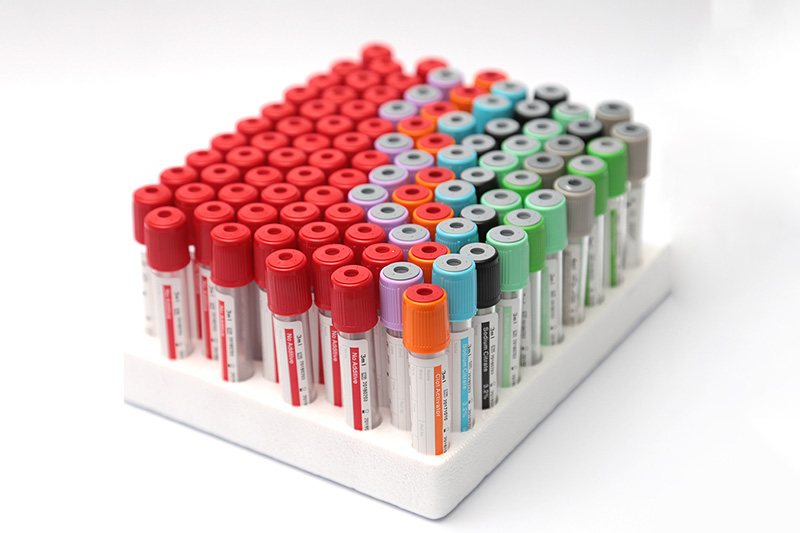

Our personnel are generally within the spirit of "continuous improvement and excellence", and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for Ampoule Washing Machine Standard Operating Procedure, Aseptic Filling For Ampoule, Vial Washing Machine Validation, Aseptic Filling For Ampoule,Syrup Preparation Machine. We play a leading role in providing customers with high quality products good service and competitive prices. The product will supply to all over the world, such as Europe, America, Australia,Zimbabwe, Hanover,Iceland, Nairobi.We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

Related Products