Explore the Future: 2025 Top Pharmaceutical Packaging Equipment Innovations

Table of Contents

- Innovative Materials Revolutionizing Pharmaceutical Packaging in 2025

- Smart Packaging Solutions: Enhancing Drug Safety and Traceability

- Automation in Packaging: Boosting Efficiency in Pharmaceutical Production

- Sustainability Trends: Eco-friendly Packaging Innovations for 2025

- Future of Serialization: Compliance and Technology Integration in Packaging

- Next-Gen Equipment: The Role of AI and IoT in Pharma Packaging Processes

- Optimizing Pharmaceutical Efficiency: Insights from the Latest Market Reports on Automatic Blister Packing & Cartoning Machines

- FAQS

- Conclusion

- Related Posts

The world of pharmaceutical packaging equipment is really gearing up for some exciting changes come 2025. Innovations are rolling in fast, focusing on making processes more efficient, safer, and greener. According to Dr. Emily Johnson, who’s pretty much a guru in pharma engineering, the future’s all about smart tech—stuff that not only speeds things up but also keeps medicines safe and effective.

At Shanghai IVEN Pharmatech, we’re totally on board with this vision. Our four specialized factories are all about developing top-notch machinery for pharma, blood collection tubes, and water treatment systems.

As we look ahead, it’s clear that trends like digital tech and automation are going to be game-changers for the industry. Companies are taking big strides toward smoother, smarter operations. Here at Shanghai IVEN Pharmatech, we’re dedicated to pushing these innovations forward, helping our clients stay ahead of the curve. We know that quality and compliance are still the name of the game, even as everything evolves.

All in all, the path toward 2025 looks pretty exciting for pharmaceutical packaging. By embracing the latest tech and listening to expert insights, we can not only improve our packaging solutions but also boost patient safety and make the whole process more sustainable. It’s a thrilling time to be in this field!

Innovative Materials Revolutionizing Pharmaceutical Packaging in 2025

The pharmaceutical packaging industry is on the brink of a revolution driven by innovative materials set to reshape the sector in 2025. According to a recent report by Research and Markets, the global pharmaceutical packaging market is projected to reach $200 billion by 2025, with an expected CAGR of 7.5%. This growth is fueled by the adoption of advanced materials like biodegradable plastics, smart packaging, and child-resistant designs that not only enhance product safety but also address environmental concerns.

These innovative materials offer pharmaceutical companies the ability to improve drug stability and shelf life. For instance, the integration of smart technology in packaging allows for real-time monitoring of temperature and humidity, ensuring optimal storage conditions. Additionally, breakthroughs in sustainable materials significantly reduce carbon footprints, appealing to a growing consumer base that values eco-friendly practices.

**Tips:** When considering the adoption of new packaging materials, ensure compliance with regulatory standards and assess the long-term cost implications. Engaging with suppliers who specialize in sustainable packaging can also provide valuable insights into the latest innovations. Staying informed about market trends through industry reports can help companies remain competitive in a rapidly evolving landscape.

Smart Packaging Solutions: Enhancing Drug Safety and Traceability

The evolution of pharmaceutical packaging is witnessing groundbreaking innovations aimed at enhancing drug safety and traceability, especially with the advent of smart packaging solutions. According to a report by Grand View Research, the global smart packaging market is projected to reach approximately $40 billion by 2025, driven by the growing need for safety measures against counterfeiting and the increasing emphasis on product integrity. These smart solutions incorporate advanced technologies such as RFID (Radio-Frequency Identification) and IoT (Internet of Things) functionalities, ensuring that pharmaceuticals maintain their effectiveness from production to patient delivery.

Moreover, regulatory bodies are placing heightened focus on traceability within the pharmaceutical supply chain. A survey conducted by PwC revealed that over 65% of executives in the pharmaceutical sector believe that implementing smart packaging could significantly reduce issues related to drug mishandling and counterfeit products. This shift towards intelligent packaging systems not only enhances compliance with stringent regulations but also empowers consumers by providing real-time information about drug origin, expiration dates, and storage conditions. As the industry progresses towards 2025, the integration of such advanced packaging technologies will undoubtedly play a critical role in shaping a safer and more transparent pharmaceutical landscape.

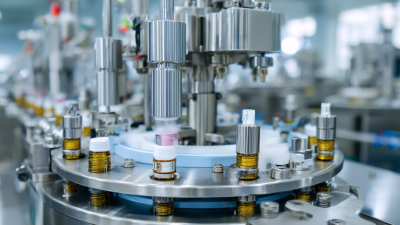

Automation in Packaging: Boosting Efficiency in Pharmaceutical Production

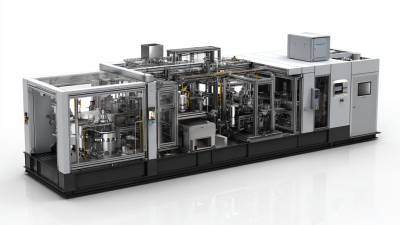

As the pharmaceutical industry continues to evolve, automation in packaging is becoming a pivotal factor in enhancing efficiency and compliance. According to a report by Grand View Research, the global pharmaceutical packaging market is projected to reach $644.3 billion by 2027, with automation playing a key role in this growth. By integrating advanced technologies such as robotics and AI-driven systems, manufacturers can streamline their packaging processes, reduce human error, and significantly lower operational costs.

In 2025, we expect to see innovations that further leverage these technologies, enabling real-time data analytics and predictive maintenance. A study by MarketsandMarkets predicts that the automated packaging equipment market is set to grow from $47.6 billion in 2020 to $69.4 billion by 2025, reflecting the increasing demand for efficient production solutions. These automated systems not only boost throughput but also enhance traceability and product safety, which are critical in the highly regulated pharmaceutical sector. With such advancements on the horizon, companies that embrace automation will likely lead the charge in setting new standards for efficiency and reliability in pharmaceutical production.

Sustainability Trends: Eco-friendly Packaging Innovations for 2025

In 2025, the pharmaceutical packaging industry is poised to embrace significant advancements driven by sustainability trends. As consumers become increasingly environmentally conscious, companies are prioritizing eco-friendly packaging solutions to minimize their ecological footprint. Innovations such as biodegradable materials and recyclable designs are at the forefront, targeting a reduction in plastic waste and promoting circular economy practices. By harnessing renewable resources, pharmaceutical manufacturers can create packaging that not only protects products but also aligns with global sustainability goals.

Another exciting development is the integration of smart technology in packaging solutions. Intelligent packaging systems can provide real-time data on product integrity and shelf life while utilizing eco-friendly materials. These innovations not only enhance consumer safety but also encourage responsible disposal methods. As the industry leans into sustainability, the evolution of intelligent packaging will empower manufacturers to meet both regulatory requirements and consumer expectations, paving the way for a greener future in pharmaceutical packaging.

Future of Serialization: Compliance and Technology Integration in Packaging

The future of serialization in pharmaceutical packaging is increasingly intertwined with compliance and technology integration. As regulatory requirements tighten, pharmaceutical companies must adapt their packaging processes to ensure transparency and traceability. Serialization, which involves assigning unique identifiers to individual packages, enhances product security and aids in combating counterfeiting. This technological advancement not only boosts consumer confidence but also ensures that manufacturers comply with stringent regulations.

The U.S. label printer market is responding to the growing demand for innovative packaging solutions driven by e-commerce expansion and technological advancements. Industries like retail, healthcare, and logistics are at the forefront of this market evolution, necessitating efficient and reliable packaging processes. In parallel, the pharmaceutical contract manufacturing sector is also evolving, with outsourced production services focusing on key activities such as active pharmaceutical ingredient synthesis and clinical trial material manufacturing. Together, these trends underline the significance of integrating advanced serialization technologies into packaging to meet both market demands and regulatory standards.

Next-Gen Equipment: The Role of AI and IoT in Pharma Packaging Processes

The pharmaceutical packaging industry is on the brink of a technological revolution, primarily driven by advancements in artificial intelligence (AI) and the Internet of Things (IoT). AI enables advanced data analytics, allowing for predictive maintenance of packaging equipment, optimizing performance, and reducing downtime. By deploying machine learning algorithms, manufacturers can not only enhance the accuracy of their packaging processes but also forecast market trends, thus enabling more efficient production schedules tailored to consumer demand.

Meanwhile, IoT technology introduces connected devices that facilitate real-time monitoring and quality control throughout the packaging process. By integrating smart sensors, companies can track environmental conditions, detect anomalies, and ensure compliance with regulatory standards. This interconnected approach not only enhances safety and traceability but also fosters a more agile supply chain, allowing pharmaceutical companies to respond swiftly to shifting market requirements. The synergy of AI and IoT in pharmaceutical packaging not only paves the way for increased efficiency but also sets the stage for innovations that prioritize patient safety and sustainability in the industry.

Optimizing Pharmaceutical Efficiency: Insights from the Latest Market Reports on Automatic Blister Packing & Cartoning Machines

In the ever-evolving pharmaceutical industry, optimizing efficiency is crucial for meeting the increasing demand for packaged medications. The latest market reports highlight the importance of automatic blister packing and cartoning machines, which are integral components of modern pharmaceutical production lines. These machines work in tandem to create a streamlined process that enhances productivity and reduces the potential for human error.

At the core of this automation are three essential machines: the blister machine, the cartoner, and the labeller. The blister machine plays a pivotal role by forming precise blister packs that protect medications from external factors while ensuring extended shelf life. Following this, the cartoner efficiently packages these blister packs into cartons, providing a protective layer and facilitating ease of handling. Lastly, the labeller ensures that each carton is accurately labeled, which is critical for regulatory compliance and for providing essential product information to consumers.

This combination of machinery not only boosts production efficiency but also enhances the overall quality of pharmaceutical packaging. As companies continue to seek ways to optimize their operations, investing in advanced blister packing and cartoning solutions will be paramount for success in a competitive market.

FAQS

: Smart packaging solutions incorporate advanced technologies like RFID and IoT to enhance drug safety and traceability, ensuring pharmaceuticals maintain effectiveness from production to patient delivery.

The market is projected to reach approximately $40 billion by 2025 due to the need for safety measures against counterfeiting and an increased emphasis on product integrity.

According to a PwC survey, over 65% of pharma executives believe that smart packaging can significantly reduce issues related to drug mishandling and counterfeiting through enhanced traceability.

Serialization involves assigning unique identifiers to individual packages, which enhances product security and aids in combating counterfeiting, ensuring compliance with regulatory requirements.

Smart packaging provides real-time information about drug origin, expiration dates, and storage conditions, thereby empowering consumers with crucial information regarding the products they use.

Heightened regulatory requirements necessitate transparency and traceability in the pharmaceutical supply chain to ensure drug safety and integrity, which smart packaging solutions help achieve.

The U.S. label printer market is evolving to meet the growing demand for innovative packaging solutions, particularly driven by e-commerce expansion and technological advancements.

Key activities include active pharmaceutical ingredient synthesis and clinical trial material manufacturing, which are essential for the evolving pharmaceutical sector and require efficient packaging processes.

The integration of advanced serialization and smart packaging technologies are expected to play a critical role in enhancing drug safety, transparency, and compliance in the pharmaceutical landscape.

Conclusion

The article "Explore the Future: 2025 Top Pharmaceutical Packaging Equipment Innovations" highlights groundbreaking advancements in the pharmaceutical packaging industry. Key innovations include the use of innovative materials that are set to revolutionize packaging, enhancing both drug safety and traceability through smart packaging solutions. Automation is significantly boosting efficiency in pharmaceutical production, while sustainability trends are paving the way for eco-friendly packaging innovations. Furthermore, advancements in serialization are ensuring compliance through technology integration, and the role of AI and IoT in next-generation pharmaceutical packaging equipment is redefining industry standards.

As a leader in pharmaceutical machinery, Shanghai IVEN Pharmatech Engineering Co., Ltd. is positioned to capitalize on these innovations with its four specialized factories focused on producing state-of-the-art pharmaceutical packaging equipment. The integration of these emerging technologies promises not only to improve production processes but also to enhance the overall safety and sustainability of pharmaceuticals in the market.

Related Posts

-

How to Select the Perfect Pharma Blister Cartoner Machine for Your Production Needs

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

7 Essential Tips to Choose the Best Leak Testing Machine Manufacturers

-

Ultimate Guide to Selecting the Best Pharmaceutical Liquid Filling Machines in 2025

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

The Future of Liquid Filling Machines: Innovations Shaping Tomorrow's Manufacturing

Blog Tags: