Unlocking Efficiency: The Advantages of Using an Automatic Vial Inspection Machine

Table of Contents

- Benefits of Automatic Vial Inspection Machines in Pharmaceutical Manufacturing

- Key Features to Look for in an Automatic Vial Inspection Machine

- How Automatic Vial Inspection Machines Improve Quality Control

- Steps to Integrate Automatic Vial Inspection Machines into Your Workflow

- Comparative Analysis: Manual vs. Automatic Vial Inspection Processes

- Future Trends in Automatic Vial Inspection Technology

- FAQS

- Conclusion

- Related Posts

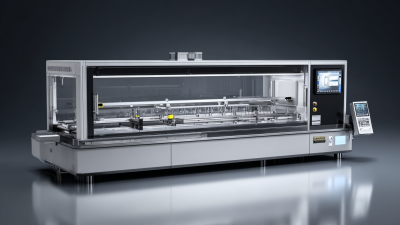

In the fast-changing world of pharmaceuticals, making sure everything is up to snuff when it comes to quality and safety is a top priority. One of the coolest recent developments? The Automatic Vial Inspection Machine. It’s a game-changer — helping to speed up the inspection process and making things run more smoothly overall. Shanghai IVEN Pharmatech Engineering Co., Ltd. is really leading the charge here, with its four really specialized factories focused on pharma equipment, blood collection tubes, and water treatment systems. By bringing the latest tech into vial inspection, our solutions don’t just help catch errors faster and more accurately — they also cut down on human mistakes, which is a big deal in pharma manufacturing. In this blog, I’ll dive into all the great advantages of using an Automatic Vial Inspection Machine in production lines, and show why this kind of tech is becoming absolutely essential to keep standards sky-high in the industry.

Benefits of Automatic Vial Inspection Machines in Pharmaceutical Manufacturing

You know, in the pharma manufacturing world, getting things just right isn’t optional — it’s absolutely crucial. That’s where

automatic vial inspection machines come into play; they’re really transforming how companies boost quality and speed up their processes. I came across a report by MarketsandMarkets that says the global market for vial inspection systems is expected to hit around

$1.5 billion by 2026 — which just shows how much automation is becoming a must-have in quality control these days. These machines do a pretty great job of cutting down human error, making sure only the best and safest products make it to the shelves. They can spot particles, cracks, or fill levels — and can scan up to

600 vials a minute! That’s impressive, right? It helps manufacturers stay on top of strict rules from agencies like the

FDA without breaking a sweat.

And here’s the bonus: switching to automated inspection can really save some cash. Frost & Sullivan did a study showing that companies that go this route can cut their operational costs by up to

30% over five years — thanks to less waste and quicker turnaround times. Plus, with cool tech like advanced imaging and AI, these machines don’t just get better at spotting issues. They can even predict when maintenance might be needed, keeping things running smoothly. As the pharma industry keeps evolving, adopting these kinds of

smart tech is going to be a big part of staying ahead — delivering top quality and efficiency hand in hand.

Key Features to Look for in an Automatic Vial Inspection Machine

When you're looking at automatic vial inspection machines for pharma, there are a few key features you really want to keep in mind—things that can make a big difference in how smoothly your production runs. For starters, it’s super important that the machine can handle different vial sizes and shapes, even those with really low fill volumes. Thanks to recent tweaks and upgrades in automated visual inspection (AVI) tech, we're now seeing fewer mix-ups where imperfections get mistaken for contaminants—big deal for keeping product quality top-notch.

Another thing that’s becoming a game-changer is the integration of AI and machine vision. These smart systems don’t just speed up the inspection process—they actually boost accuracy too, by analyzing the specific details of lyophilized vials. With AI involved, manufacturers can cut down on variability and set a higher bar for quality, all while reducing the errors and delays that come with manual checks.

Tip 1: Make sure whatever machine you go for can handle different vial styles and fill levels. It’s a simple way to dodge costly mistakes that might lead to recalls.

Tip 2: Opt for systems that feature real-time data analytics—these let you constantly tweak and improve the inspection process and can even help minimize downtime.

Investing in a top-notch automatic vial inspection machine isn’t just about staying current; it’s about making your production line work more efficiently and reliably, especially with how fast the pharma world is changing these days.

How Automatic Vial Inspection Machines Improve Quality Control

Automatic vial inspection machines are really changing the game in the pharmaceutical world. Have you seen that recent report from MarketsandMarkets? It says the global market for these inspection systems is expected to hit around $1.24 billion by 2025. Why? Well, with more folks needing meds these days and the industry tightening up on quality control, there's a huge push for smarter, faster solutions. These high-tech machines use stuff like image processing and AI to spot any defects in vials almost instantly, making sure only the best products end up in consumers’ hands.

At Shanghai IVEN Pharmatech Engineering Co., Ltd., we totally get how important both speed and accuracy are in pharma manufacturing. That’s why we’ve set up four specialized factories focused on making top-notch pharmaceutical equipment, including automatic vial inspection machines. Putting these systems in place has been a game changer—it can cut defect rates by as much as 90%. That means fewer recalls and simpler compliance with strict regulations. As quality control continues to be a priority, we’re proud to push the boundaries and set new standards for what’s possible in the industry.

Steps to Integrate Automatic Vial Inspection Machines into Your Workflow

Bringing automatic vial inspection machines into pharma and biotech workflows can really give your operations a boost—improving both efficiency and the quality of your products. I read somewhere that, according to McKinsey & Company, automating quality checks can boost productivity by up to 30%. That’s a pretty big deal! It means fewer mistakes from humans and faster processing, so companies can keep up with the increasing global demand without sacrificing compliance with strict regulations.

If you're thinking about making the switch, a good first step is to take a close look at your current processes and figure out where the biggest bottlenecks are. Trying out the new tech in phases, maybe through pilot tests, can help iron out any kinks along the way. Interestingly, a study in the Journal of Pharmaceutical Sciences found that facilities using automated inspection systems cut their inspection times by around 50%, which means getting important products to market quicker.

And don’t forget: training your team to work alongside these new machines is a must. Making sure staff are comfortable with the technology and know how to troubleshoot when needed will help everything run smoothly. Basically, a thoughtful approach, some training, and patience can really pay off in the long run with better efficiency and quality.

Comparative Analysis: Manual vs. Automatic Vial Inspection Processes

When it comes to the pharmaceutical world, precision and efficiency in inspecting vials really matter. For a long time, folks have relied on manual checks—yeah, those hands-on inspections—but let’s be honest, they’re not perfect. Human errors happen, and it can slow things down quite a bit. That’s where automatic vial inspection machines come into play. These nifty gadgets speed things up and get things right more often than not. They use cutting-edge tech to spot defects, making sure only top-quality products make it to the shelves.

Thinking about switching from manual to automatic? Here’s a tip: take a good look at what your production line really needs. Find machines that are a good fit—ones that can slide right into your existing setup and maybe even let you tweak settings for different vial types. It makes life way easier.

Plus, these machines don’t just inspect—they also collect detailed data. This helps you keep an eye on quality, stay compliant with regulations, and catch issues early on. By removing the variability that comes with human inspection, your operation can run smoother, save money, and cut down on costly recalls or reworks.

And a quick heads-up—regular maintenance and calibration are super important. Keeping your machine in shape ensures it stays accurate and reliable, so your inspection process doesn’t skip a beat.

Unlocking Efficiency: The Advantages of Using an Automatic Vial Inspection Machine

Future Trends in Automatic Vial Inspection Technology

The world of automatic vial inspection tech is changing pretty fast, mainly thanks to all the advances in AI and machine learning we've been seeing lately. I came across a recent report from Grand View Research, and it states that the global market for automatic inspection equipment might hit around $2.2 billion by 2025. That's a solid growth rate of about 8.4% annually. It kind of shows just how much demand there is for smarter, more reliable quality control systems—especially in pharma and cosmetics, where making sure vials are safe and intact is absolutely critical.

Looking ahead, it seems like we’ll see a big shift towards vision systems that can spot even tiny defects—like tiny cracks or bits of dust—pretty much in real-time. The use of 3D imaging tech is also expected to improve detection accuracy quite a bit. According to MarketsandMarkets, these new systems with advanced analytics and instant feedback features will help make production more efficient, cut down on waste, and help companies stay on top of all the tightening regulations. Honestly, as these technologies keep getting better, companies that jump on board early are probably gonna enjoy smoother operations and save quite a bit on manual inspection costs. It’s an exciting time for this industry, for sure.

FAQS

: Automatic vial inspection machines enhance production quality and streamline processes by significantly reducing human error, ensuring compliance with regulatory standards, and allowing for speeds of up to 600 vials per minute.

According to a report by MarketsandMarkets, the global vial inspection systems market is expected to reach $1.5 billion by 2026.

Companies that utilize automated inspection can reduce operational costs by up to 30% over five years by minimizing wastage and speeding up production times.

These machines incorporate advanced imaging technologies and artificial intelligence to improve detection accuracy and enable predictive maintenance.

Key features to consider include the machine's ability to adapt to various vial specifications, integration of AI and machine vision technologies, and handling of low fill volumes.

Ensuring the machine can handle a range of vial types and fill levels prevents errors that could lead to costly product recalls.

Systems that incorporate real-time data analytics enable continuous improvement in inspection quality and can reduce downtime in production lines.

They address challenges such as the misidentification of vial imperfections as contaminants, crucial for maintaining product quality.

AI improves accuracy by analyzing the unique structures of lyophilized vials, mitigating variability, and enhancing inspection standards compared to manual methods.

Investing in an advanced automatic vial inspection machine contributes to a more efficient production line, meeting the growing demands for quality and efficiency in the pharmaceutical industry.

Conclusion

When it comes to pharmaceutical manufacturing, adding an Automatic Vial Inspection Machine really makes a difference. It helps boost efficiency and overall product quality in a big way. These machines make the inspection process much smoother—cutting down on human errors and allowing more vials to be inspected faster. Some of the key features to look out for include sharp imaging tech, quick processing speeds, and easy-to-use interfaces. All of these together really strengthen the quality control side of things and help keep up with strict regulations.

Getting one of these machines up and running in your existing workflow isn’t too complicated either. With a bit of planning, you can make the transition smoothly without disrupting your daily operations. When you compare manual inspection to automation, there’s really no contest—it’s more accurate and reliable, plain and simple. As technology keeps advancing, companies like Shanghai IVEN Pharmatech are leading the charge with innovative solutions for pharma production. They’re all about helping the industry stay ahead, prioritizing both quality and efficiency every step of the way.

Related Posts

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

-

The Definitive Handbook to Automated Inspection Machines in the Pharma Industry

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

7 Compelling Reasons to Choose the Best Clean Steam Generator Manufacturers for Your Business Needs

-

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

-

The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

Blog Tags: