Unraveling the Future: How Automated Filter Tube Production is Revolutionizing Industry Standards

Table of Contents

- The Rise of Automated Filter Tube Production in Modern Manufacturing

- Key Technologies Driving Automation in Filter Tube Production

- Cost Efficiency and Productivity Gains from Automated Systems

- Quality Control Innovations in Automated Filter Tube Manufacturing

- Future Trends: What’s Next for Filter Tube Automation?

- Sustainability: How Automation Is Reducing Environmental Impact in Production

- Innovative Solutions for Efficient Mini Vacuum Blood Collection Tube Production Lines

- FAQS

- Conclusion

- Related Posts

The way things are made is seriously changing right now, and Automated Filter Tube Production is really leading the charge. As industries push for more efficiency and precision, automating these processes has proven to boost production, cut down on labor costs, and even minimize mistakes. If you check out the latest report from MarketsandMarkets, they say the global filtration market might hit around $64.86 billion by 2026. That just goes to show how important advanced manufacturing techniques are becoming to meet the ever-increasing industry standards.

Dr. Michael Thompson, who’s kind of a big deal in filtration tech, really drives this point home. He mentioned, “Automated Filter Tube Production isn’t just a passing trend; it’s a game-changer that’s setting new standards for quality and efficiency across the board.” That really hits the mark — everyone’s starting to see how automation isn’t just about speeding things up, but also about making products last longer and work better. As demand for different kinds of filters keeps climbing, being able to automate production is pretty much a must for companies that want to stay competitive in this fast-paced market.

In this article, we’re gonna dig into how Automated Filter Tube Production is transforming industry standards — from making operations smoother, to boosting product quality, and even helping out with sustainability goals. Moving forward, integrating these kinds of cutting-edge tech is going to be key for manufacturing. And for anyone involved in the supply chain, understanding what these changes mean is more important than ever.

The Rise of Automated Filter Tube Production in Modern Manufacturing

The rise of automated filter tube production is really shaking things up in the food and beverage filtering world. These days, industries are turning more and more to automated systems because they offer a huge boost in efficiency and precision. It’s not just about speeding things up—these systems also improve the quality of the final product, which is super important given how much demand there is for top-notch filtration solutions. You’ll notice that the market is diversifying quite a bit too, with new types like HEPA, ULPA, and a variety of cartridge filters coming into play, all thanks to tech advancements and what consumers are looking for.

Looking ahead, between 2026 and 2035, it’s expected that the hydraulic market will hit around $45.33 billion, growing at a steady rate of over 3.2% each year. That growth mainly comes down to smarter automation and better integration techniques, which are helping tackle some pretty tricky installation challenges. As these automated processes keep getting better, they’re set to become even more crucial for meeting the high standards for efficiency and sustainability that modern manufacturing demands. It’s pretty clear they’re going to be a key part of how things evolve in the industry moving forward.

Key Technologies Driving Automation in Filter Tube Production

The world of filter tube manufacturing is really going through a major transformation lately, thanks to all these new automation tech. More and more companies are starting to see that bringing automation into the mix can seriously boost their production capacity, making things faster and easier to scale up. I recently came across a survey where most manufacturers said automation is a key part of their growth plans — it’s no joke. This shift isn’t just about making processes smoother; it’s also opening up new jobs in the industry, which is pretty important as markets continue to change and demand more innovative solutions.

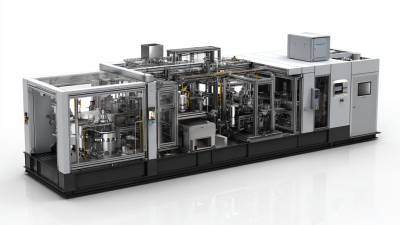

What’s really driving this change are some pretty cool tech like advanced robotics, AI-powered quality checks, and super precise metrology tools. These innovations help companies fine-tune their production lines, cut down waste, and keep product quality consistently high. For example, some systems even monitor everything in real-time, so if something’s off, they can fix it on the fly — pretty neat, right? As companies like GEA invest in smarter factories and automation, it looks like the future of filter tube manufacturing is headed for some exciting growth — setting new standards and all that jazz.

Cost Efficiency and Productivity Gains from Automated Systems

You know, these days, using automated systems for making filter tubes is really changing the game in the industry. It’s like a huge jump forward in saving money and boosting productivity. Before all this, most of the process was pretty much manual—lots of hard work, high costs, and slower output. But now, with automation, companies can actually speed things up, cut down on waste, and get each unit out the door faster. That means they can not only save money but also react quicker to what the market wants, giving them a real edge over the competition.

And honestly, the best part? The precision automation brings ensures every filter tube is up to snuff — no sloppy errors. This consistency helps dodge costly mistakes that could hurt their budget or reputation. So, by jumping on the automation bandwagon, businesses aren’t just saving cash; they’re also making better products that keep customers happy. All in all, moving toward automated filter tube production is a pretty big step forward in making things run smoother and more efficiently in this industry.

Quality Control Innovations in Automated Filter Tube Manufacturing

You know, the way automated filter tube manufacturing has evolved is pretty remarkable, especially when it comes to how they handle quality control. I was reading this report from Grand View Research, and it’s pretty exciting to see that the global market for industrial filtration could hit around $60.45 billion by 2025. A big part of that growth is thanks to new tech in production and a stronger focus on ensuring top-notch quality. These days, automation isn’t just about speed — it can actually spot defects at different stages of making the tubes, using some pretty advanced algorithms and machine learning. It’s like having a super-smart inspector watching over everything.

And get this — with systems that monitor everything in real time and crunch data like pros, the quality control game is getting even better. MarketsandMarkets pointed out that automating manufacturing can cut down defects by about 30% and boost efficiency by roughly 25%. The machines analyze tons of data as they work, catching anything that looks off and making instant adjustments. That means the filters are not only better quality, but they’re also more sustainable — wasting less material and using resources smarter. Honestly, the future of automated filter tube making isn’t just about being fast — it’s about setting new standards for quality and reliability that could really shake up the industry.

Unraveling the Future: How Automated Filter Tube Production is Revolutionizing Industry Standards - Quality Control Innovations in Automated Filter Tube Manufacturing

| Production Method | Filter Tube Material | Quality Control Process | Output Rate (units/hour) | Defect Rate (%) |

|---|---|---|---|---|

| Automated Injection Molding | Polypropylene (PP) | Visual Inspection + Automated Testing | 1200 | 0.5 |

| CNC Machining | Stainless Steel | Laser Measurement + Quality Indexing | 800 | 1.2 |

| 3D Printing | Polycarbonate (PC) | Post-Production Stress Testing | 500 | 3.0 |

| Thermoforming | PVC | Automated Dimensional Checks | 1000 | 1.0 |

| Filtration Layer Bonding | Fiberglass | Continuous Flow Monitoring | 700 | 0.8 |

Future Trends: What’s Next for Filter Tube Automation?

Looking ahead, the future of filter tube automation is really exciting, with big leaps expected as more industries start to embrace smarter tech to boost production. We're seeing a clear move toward smart manufacturing — you know, systems that use artificial intelligence and machine learning to streamline everything. By automating quality checks and real-time monitoring, companies can cut down on human mistakes, waste less, and get those filter tubes dialed in to perfect dimensions. Not only does this mean better performance, but it also speeds up getting products out to customers faster.

And honestly, sustainability is becoming a huge deal in all this. Future solutions are likely going to focus on eco-friendly materials and greener processes. Manufacturers are really trying to shrink their carbon footprints by investing in energy-efficient machines and recyclable materials. It’s all about aligning with stricter environmental rules and what customers are asking for these days. As automation keeps leveling up, pushing sustainable practices will probably set new industry standards—driving innovation and helping companies stay competitive in the market. Pretty exciting times, right?

Sustainability: How Automation Is Reducing Environmental Impact in Production

You know, as industries all over the world are really pushing for sustainability, automation is quickly becoming a game-changer when it comes to cutting down environmental impact during production.

Take automated filter tube manufacturing, for example — it doesn’t just boost efficiency; it also helps cut back on waste and saves resources. When manufacturers bring in advanced robotics and AI systems, they can fine-tune their processes, making sure materials and energy aren't wasted. That shift toward automation means they can produce with more precision, which definitely means higher quality products and fewer flaws. All of this adds up to helping keep our planet cleaner, bit by bit.

If you’re thinking about jumping into automation, start by taking a good look at your current operations. Find those spots where automating could really make a difference—whether it's reducing waste or speeding things up. Investing in energy-efficient machines is a good move, and don’t forget about software tools that give you real-time updates on resource usage. Plus, training your team on new tech is super important — it helps everything roll out smoothly and gets everyone on the same page.

And here’s a bonus: automated systems can also make your supply chains way more efficient. Automating inventory checks and scheduling means less transportation emissions and lower energy bills. Basically, embracing automation isn’t just good for the environment — it can also help your business grow in a smart, sustainable way, especially since more customers are now really into eco-friendly practices.

Innovative Solutions for Efficient Mini Vacuum Blood Collection Tube Production Lines

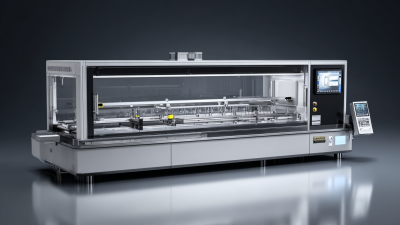

The demand for mini vacuum blood collection tubes is rising rapidly, driven by advancements in medical diagnostics and home healthcare. Innovative production lines are crucial for keeping pace with this growing need, ensuring not only efficiency but also quality in manufacturing. Modern systems for producing blood collection tubes integrate several critical steps, including tube loading, chemical dosing, drying, stoppering, vacuuming, and tray loading. These processes are designed for seamless operation, significantly enhancing productivity while maintaining rigorous safety and quality standards.

According to recent industry reports, the global blood collection tubes market is projected to reach USD 3.5 billion by 2025, growing at a CAGR of 6.5%. To capitalize on this growth, manufacturers are increasingly investing in advanced production lines that incorporate individual PLC and HMI controls. This technological integration allows for easy and safe operation, enabling just one or two workers to manage the entire production line effectively. Such efficiency not only reduces labor costs but also minimizes the potential for human error, ensuring that each tube meets the stringent requirements set forth by health regulators.

As the healthcare landscape evolves, the shift towards automation in blood collection tube production isn't merely a trend—it's a necessity. With automated systems, companies can achieve consistent output quality while responding swiftly to market fluctuations. By adopting these innovative solutions, manufacturers can position themselves at the forefront of the industry, enhancing their competitiveness and ensuring the availability of reliable blood collection tools that healthcare providers depend on.

FAQS

: The key technologies include cutting-edge robotics, AI-driven quality control systems, and advanced metrology tools, all of which optimize production lines and enhance efficiency.

Automation streamlines the manufacturing process, reducing production time and minimizing waste, leading to lower operational costs and higher productivity.

Automated systems ensure high precision and consistency in production, decreasing the likelihood of errors and improving overall product quality, which enhances customer satisfaction.

Automation reduces waste and resource consumption by optimizing processes, leading to more precise manufacturing with higher quality products and fewer defects, thus benefiting the environment.

Companies should conduct a thorough assessment to identify areas for improvement, invest in energy-efficient machinery, and provide training for employees on new technologies.

By automating inventory management and production scheduling, companies can lower transportation emissions and energy consumption, contributing to a more sustainable business model.

While automation streamlines processes, it also leads to the creation of new manufacturing jobs as industries adapt to modern technologies.

Automation allows manufacturers to respond swiftly to market demands, enabling faster production rates and a competitive edge.

Manufacturers recognize that automation enhances production capabilities, leading to improved efficiency, scalability, and overall competitiveness in the market.

Conclusion

The article titled "Unraveling the Future: How Automated Filter Tube Production is Changing the Game" takes a pretty interesting look at how automation is really shaking up the filter tube manufacturing world. It points out that automated filter tube production has become a go-to solution in today’s fast-paced manufacturing scene, highlighting some of the coolest tech that’s making all this possible. By bringing in top-notch automation systems, companies are not only saving a bunch of money and ramping up productivity, but they’re also improving quality control—meaning the products are more reliable than ever.

Plus, the piece touches on what’s coming next in filter tube automation. It’s exciting to see how these new developments will keep pushing the industry forward. Sustainability is also a big deal here—automation isn’t just about efficiency anymore; it’s about being kinder to the environment too, which is a huge plus given the global move towards greener ways of doing things. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are leading the charge, transforming how pharmaceutical and medical equipment are made with cutting-edge automated tech. It’s pretty fascinating to see how all these pieces are coming together to reshape the manufacturing landscape.

Related Posts

-

Top Strategies for Ensuring the Validation of Capsule Filling Machines in Pharmaceutical Production

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Ultimate Checklist for Selecting the Right Vial Filling Equipment

-

7 Essential Tips for Choosing the Right Blow Fill Seal Manufacturers for Your Business

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

-

How Vial Filling Machines Revolutionize the Pharmaceutical Industry: A Closer Look

Blog Tags: