The Definitive Handbook to Automated Inspection Machines in the Pharma Industry

Table of Contents

- The Role of Automated Inspection Machines in Enhancing Pharma Quality Control

- Key Features of Automated Inspection Machines for Pharmaceutical Products

- Impact of Regulatory Standards on the Design of Inspection Automation Systems

- Cost-Benefit Analysis: Implementing Automated Inspection in Pharma Manufacturing

- Future Trends in Automated Inspection Technology within the Pharmaceutical Sector

- Real-world Case Studies: Success Stories of Automation in Pharma Inspections

- Efficiently Streamline Your Pharmaceutical Production with the 30ml Glass Bottle Syrup Filling and Capping Machine

- FAQS

- Conclusion

- Related Posts

The pharma industry is really going through a major shift these days, thanks to some pretty cool new technologies. You know, especially in areas like quality control and making sure everything meets strict standards. Industry experts are saying that the global market for automated inspection machines in pharma is set to hit around $1.5 billion by 2025, growing close to 10% CAGR from 2020 onwards—that’s quite rapid!

These Automated Inspection Machines are a huge help in keeping product quality top-notch and ensuring companies stay compliant, while also cutting down on human errors and boosting overall efficiency. Companies like Shanghai IVEN Pharmatech are leading the charge—operating four state-of-the-art factories focused on pharma machinery, blood collection tubes, and water treatment equipment. By adopting these advanced, automated inspection techs, IVEN is pretty much positioned to lead the way in delivering reliable, high-quality meds, which basically means safer, better healthcare for everyone. It’s an exciting time for the industry, no doubt!

The Role of Automated Inspection Machines in Enhancing Pharma Quality Control

You know, automated inspection machines have really become a key player in quality control for the pharmaceutical world. They’ve made the whole process way more accurate and faster, which is a big deal. I read a report from the International Society for Pharmaceutical Engineering (ISPE) that says using these systems can cut down human errors by over 90%. That’s huge, especially since it lines up with FDA rules that require strict quality checks. Honestly, these stats just highlight how crucial automation is for staying compliant and making sure medicines work as they should.

And it gets better — a 2023 study in the Journal of Pharmaceutical Sciences found that places using these automated machines saw about a 30% boost in their production speed and roughly 25% lower operational costs. These machines are pretty impressive at catching even the tiniest flaws in packaging or product quality, which is super important for keeping consumers safe and ensuring the products are reliable. As the industry keeps evolving, the need for better quality control tools keeps growing, so companies are pushing harder to adopt these advanced automated systems that can provide thorough and consistent testing from start to finish.

Key Features of Automated Inspection Machines for Pharmaceutical Products

Automated inspection machines are a game-changer in the pharmaceutical world. They really help ensure that products meet strict quality standards and comply with all the crazy regulations out there. These high-tech systems are pretty amazing—they can spot flaws in packaging, labels, and even the actual product, all while cutting down on human errors and speeding up the whole process. Some of their coolest features? Fast processing speeds, clever image recognition tech, and solid quality control measures. All of this keeps the medicinal stuff safe and top-notch from start to finish.

Lately, we’ve seen some exciting shifts thanks to new advancements in industrial automation. High-performance sensors are now being used to tackle tricky inspection tasks, which helps manufacturers run things more smoothly and accurately. It’s all about making production smarter, especially in pharma, where efficiency and reliability are super important. Companies like Shanghai IVEN Pharmatech Engineering are pouring resources into cutting-edge machinery and automation, moving the industry closer to producing medicines more efficiently and consistently. It’s pretty fascinating to see how all these innovations are shaping the future of pharma manufacturing.

Impact of Regulatory Standards on the Design of Inspection Automation Systems

The pharma industry is pretty tightly regulated, right? These rules really shape how automated inspection machines are designed. They’re all about making sure the products stay safe, effective, and high quality—that’s the bottom line. When companies jump into automation, they have to make sure their inspection systems check all the boxes for what authorities like the FDA or EMA require. It’s not just about avoiding legal trouble; it’s also super important for keeping customer trust and maintaining a good reputation.

Here's a tip, though: when you're designing these systems, it’s a smart idea to build in some flexibility. Regulations can change, and having modular parts that are easy to upgrade means you won’t need to tear everything down and start over every time there’s a new rule.

And don’t forget, these machines need solid data management features. They should be able to gather and report data in real time, making audits and inspections much smoother. Keeping detailed records of inspections and results helps companies respond quickly to any regulatory questions and shows they’re committed to top-notch standards.

Another tip—invest some time into training your team on both the ins and outs of regulatory requirements and how the automated systems work. A knowledgeable crew can better anticipate upcoming changes and keep the entire process compliant and running without a hitch.

Cost-Benefit Analysis: Implementing Automated Inspection in Pharma Manufacturing

Switching over to automated inspection machines in pharma manufacturing can really make a difference—think big savings and a boost in overall efficiency. It’s all about weighing the upfront costs against the long-term benefits. When manufacturers look at things like initial equipment investment, they should also consider expenses like maintenance, staff training, and potential downtime. Sometimes, it helps to step back and compare the price of buying the machines with how much money you'll save over time by cutting labor costs and reducing mistakes.

A few tips for making this kind of rollout work smoothly? First off, do a deep dive into your costs—not just hardware, but the ongoing upkeep and training too. It’s super important to get everyone on the same page early on, involve all the stakeholders, and communicate clearly about what you’re aiming to achieve with the automated system. Plus, investing in proper training for your team is key—making sure they know how to operate and troubleshoot the new gear can save a lot of headaches later.

Another thing to consider is your current production volume and where you’re headed in the future. Picking a system that’s flexible and can grow with your needs will save you from having to upgrade too often. And don’t forget—keep an eye on how these machines perform after they’re up and running. Regular reviews will help you make tweaks, improve performance, and get the most bang for your buck.

Getting a good handle on all these aspects is crucial for a smooth transition into automated inspection—and ultimately, for getting the most out of your investment in pharma manufacturing.

Future Trends in Automated Inspection Technology within the Pharmaceutical Sector

Looking ahead, the future of automated inspection tech in pharma feels like it's headed for some pretty exciting changes, mainly thanks to advances in AI and the ongoing push for more efficient manufacturing. As the market for Vision Inspection Systems keeps growing—there are even predictions suggesting it’ll be worth a lot more by 2032—AI is really starting to take center stage. This shift means better detection of defects and upgraded quality checks during production, which ultimately helps keep patients safe and ensures the meds are reliable.

There's also a real push for more flexible processing methods, which totally makes sense given how the pharma world is evolving. More and more companies are adopting autonomous tools to boost quality and productivity, especially as they face the tricky challenges of drug delivery systems. With innovations like AI, machine learning, and smarter imaging, manufacturers can simplify their processes, cut down on human errors, and speed things up. As these techs get even better, I think they're going to completely change how quality control is done, which is super important for maintaining the trust and integrity of pharmaceutical products.

Real-world Case Studies: Success Stories of Automation in Pharma Inspections

You know, in the fast-changing world of pharma, automated inspection machines are practically a must-have now. They’re really key when it comes to making sure products are top quality and meet all necessary standards. Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we’ve been leading the charge in this whole shift—using the latest tech to make inspection processes smoother and more reliable. We’re super proud of our wide range of cutting-edge pharmaceutical machinery and specialized equipment, all designed to handle the tough demands of today’s market and keep everything running just right.

If you look at real-world examples, it’s pretty clear how much automation can make a difference. Take, for instance, one of the big pharma companies that used our automated inspection system — they managed to cut their inspection time in half, and accuracy actually got better too. That kind of success really highlights why bringing technology into daily operations is so important. It’s not just about being efficient; it’s also about making sure safety and quality standards don’t slip. As we keep developing new solutions, we’re more committed than ever to helping our clients deliver safe, high-quality products that people can trust worldwide.

Efficiently Streamline Your Pharmaceutical Production with the 30ml Glass Bottle Syrup Filling and Capping Machine

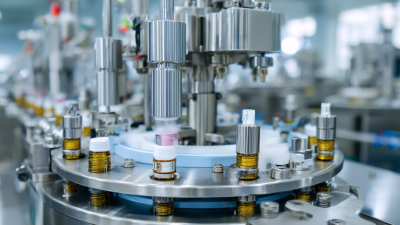

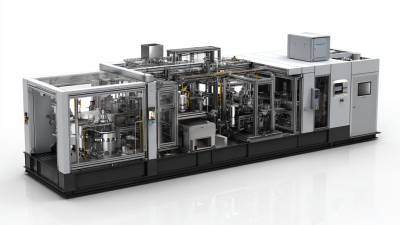

In the fast-paced world of pharmaceutical production, efficiency is key. The 30ml Glass Bottle Syrup Filling and Capping Machine offers an innovative solution to streamline your operations. This advanced machine integrates multiple crucial functions into a single, seamless process, significantly reducing production time and minimizing the potential for human error. With components such as the CLQ ultrasonic washing, RSM drying & sterilizing machine, and the DGZ filling & capping machine, this system ensures that every step from washing to capping is performed to the highest standard.

One of the standout features of the IVEN Syrup Filling and Capping Machine is its versatility. Not only does it facilitate ultrasonic washing and air charging, but it also accommodates optional drying and sterilizing processes. This multifunctional capability makes it suitable for syrup and other small dose solutions, which are essential in pharmaceutical manufacturing. Furthermore, when combined with an efficient labeling machine, it creates an ideal production line that enhances productivity while maintaining product quality.

Investing in the IVEN Syrup Filling and Capping Machine means investing in a streamlined production process that meets the demands of today’s pharmaceutical industry. By choosing this machine, companies can expect to see a significant boost in efficiency, ensuring that they keep pace with increasing market demands while adhering to stringent quality standards.

FAQS

: Automated inspection machines enhance the accuracy and efficiency of production processes, significantly reducing human error and ensuring compliance with stringent quality assurance measures.

The integration of automated systems can reduce human error by over 90%.

Facilities employing automated inspection machines reported a 30% increase in throughput and a 25% decrease in overall operational costs.

They are designed to detect flaws in drug packaging, labeling, and product integrity.

Key features include high-speed processing capabilities, image recognition technology, and robust quality control mechanisms.

By accurately detecting defects, they maintain consumer safety and product reliability, ensuring that pharmaceutical products meet regulatory standards.

Innovations such as high-performance sensors are being employed to tackle demanding inspection tasks, enhancing operational accuracy and efficiency.

The demand is rising due to the need for enhanced quality control mechanisms that ensure rigorous and consistent testing throughout the production cycle.

Conclusion

So, there's this blog titled "The Definitive Handbook to Automated Inspection Machines in the Pharma Industry," and honestly, it’s a pretty in-depth look at how these machines are a game-changer for quality control in pharma manufacturing. It dives into the must-have features that these inspection systems should have to keep products safe and reliable. Plus, it touches on how strict regulatory standards shape the design of these automated tools—because, let’s face it, compliance isn’t optional in the pharma world.

They also break down the costs involved with implementing automated inspection machines—showing how, in the long run, it can save money and boost efficiency. The article doesn’t stop there either; it points to future trends in inspection tech and throws in some real-world case studies to show how companies like Shanghai IVEN Pharmatech Engineering are actually making it work in real life. Basically, by adopting cutting-edge inspection tech, these companies can seriously step up their game in manufacturing and overall product quality, setting some pretty high standards in the pharma industry.

Related Posts

-

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

Blog Tags: