Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

Table of Contents

- Factors to Consider When Selecting a Capsule Filling Machine in China

- Understanding the Different Types of Capsule Filling Machines Available

- Key Specifications and Features That Impact Machine Efficiency

- Market Trends: The Growing Demand for Capsule Filling Machines in China

- Comparative Analysis of Leading Capsule Filling Machine Manufacturers

- Cost-Benefit Analysis: Investment in Capsule Filling Machines vs. Production Efficiency

- Maximize Efficiency in Your Supplement Business with the Ultimate Capsule Filling Machine

- FAQS

- Related Posts

In the fast-moving world of pharma, picking the right equipment can really make or break your operations and the quality of your products. One of the key pieces of gear in making capsules is, of course, the capsule filling machine. And guess what? Chinese-made machines are pretty popular right now—they’re known for being pretty high-tech and budget-friendly.

Shanghai IVEN Pharmatech Engineering Co., Ltd. is a big name in this space, with four dedicated factories that produce top-notch pharmaceutical machinery, blood collection tube equipment, water treatment systems, and more. If you're trying to figure out which capsule filling machine to go for, I’ve put together this handy checklist.

It covers all the important features, specs, and things to watch out for, so you can make a smart choice that fits your production needs and quality standards. With the right equipment in your corner, you’ll be able to ramp up your capacity and keep pace with the growing market demand.

Shanghai IVEN Pharmatech Engineering Co., Ltd. is a big name in this space, with four dedicated factories that produce top-notch pharmaceutical machinery, blood collection tube equipment, water treatment systems, and more. If you're trying to figure out which capsule filling machine to go for, I’ve put together this handy checklist.

It covers all the important features, specs, and things to watch out for, so you can make a smart choice that fits your production needs and quality standards. With the right equipment in your corner, you’ll be able to ramp up your capacity and keep pace with the growing market demand.

Factors to Consider When Selecting a Capsule Filling Machine in China

When you're looking to choose a capsule filling machine in China, there are a few key things you really wanna keep in mind to make sure you get the best performance and efficiency. First off, think about the machine's production capacity—that's a biggie. Depending on what your business needs, you gotta check if the machine can handle the amount of capsules you want to fill, and whether it’s fast enough and efficient enough for your workflow. Also, don’t forget about how adaptable it is — can it handle different capsule sizes or types? Having that kind of flexibility can really make a difference in how versatile your production line is.

Another important point is the quality of the parts used in the machine. You wanna go for something built from durable materials—that way, it’ll last longer and stay reliable over time. Features like high-quality seals, designs that are easy to clean, and interfaces that don't make you wanna pull your hair out are total plus points because they make operation and maintenance way simpler. And yeah, it’s also super important to check if the manufacturer offers good technical support and spare parts availability. That can save you a lot of trouble down the line, especially when it comes to fixing things quickly and avoiding downtime. Keeping these factors in mind will help you pick a capsule filling machine that not only meets your current needs but also sets you up for future growth and success.

Understanding the Different Types of Capsule Filling Machines Available

When you're looking into the different kinds of capsule filling machines out there, it's really important to get a grip on the tech behind them. Basically, you have two main types: manual and automatic. Manual machines are great if you're just starting out or working on a small scale—they're simpler and usually cheaper, which is a big plus. On the flip side, if you’re running larger production lines, automatic capsule fillers tend to be the go-to. They use more advanced tech to provide better accuracy and faster processing. Plus, they can handle all sorts of formulations—powders, pellets, granules—you name it—so they’ve got versatility that’s perfect for the changing needs of the nutraceutical world.

Lately, there’s been some pretty exciting advancements in capsule tech. For example, new focus areas like dry powder inhalers (DPIs) and liquid-filled gelatin capsules are gaining traction. Researchers are also digging into how capsules dissolve, especially when incorporating cross-linking agents, which could lead to better drug delivery systems. And then there’s the whole issue of static electricity during filling—studies are showing how electrode charges can impact the process, giving manufacturers ideas on how to optimize performance. With the capsule filling market expected to grow a lot in the next few years, understanding these tech developments is going to be super important for any business thinking about jumping into capsule production.

Capsule Filling Machines in China - Types and Uses

Key Specifications and Features That Impact Machine Efficiency

When you're on the hunt for the best capsule filling machine in China, it's really important to get a grip on the key specs and features that can make or break its efficiency. One of the biggest factors is how much it can produce—usually measured in capsules per hour. From what I’ve seen in industry reports, top-notch, high-efficiency machines can crank out over 40,000 capsules every hour. That’s a huge boost in productivity and can seriously cut down on costs. And, of course, this number is linked to the machine’s overall design and tech—like whether it uses volumetric or weight-based filling methods.

Another thing to keep in mind is how much automation the machine has. The fancier models now come with features like automatic capsule sorting and filling, which really helps cut down on human error and keeps the capsules consistent in weight and quality. Some studies even suggest that these automated setups can boost efficiency by up to 30%, letting you get things done quicker and with better results. Plus, features like adjustable dosage settings and easy-to-clean parts make the machines more versatile and help you stay in line with GMP standards—pretty much essential if you're working in pharma or health supplements. All in all, choosing the right machine isn’t just about capacity, but also how smoothly it runs and how well it fits your needs.

Market Trends: The Growing Demand for Capsule Filling Machines in China

So, it’s pretty clear that the demand for capsule filling machines in China is really picking up. Market trends are pushing this growth forward, and if you look at the big picture, by 2033, the global market for coffee pods and capsules is expected to hit around $5.37 billion—up from about $4.69 billion in 2025. That’s a solid annual growth rate of roughly 7%. A big reason? People are getting way more into dietary supplements lately, which has really boosted the market for liquid-filled capsules. Folks are becoming more health-conscious these days, and that shift is driving the demand for better, more efficient capsule filling solutions.

Major players in the pharma equipment scene, like Dongfulong, are taking notice and rolling out new strategies to keep up with this booming demand for more advanced capsule filling machines. Since pharmaceutical equipment plays such a crucial role in drug manufacturing and packaging, companies are really focusing on innovation and new tech to stay ahead. This makes sense because the market for capsule filling machines itself is expected to grow from about $5.23 billion in 2019 to around $8.37 billion by 2032—at a CAGR of roughly 3.2%. Basically, there's a growing appetite for machinery that’s faster, more reliable, and super efficient.

Comparative Analysis of Leading Capsule Filling Machine Manufacturers

Thinking about buying a capsule filling machine in China? Well, doing a bit of a comparison between the top manufacturers really helps you make a smarter choice. Some of the main players you’ll come across are Guangzhou Dongsun, TSHS, and ACG Worldwide. Each of these brands offers something a little different — whether it's bigger machine capacities, more automation, or simpler maintenance. For example, Guangzhou Dongsun is known for its tough machines that are perfect if you're looking to produce loads of capsules, while TSHS tends to focus on making machines that are super user-friendly, so you don’t get bogged down with complicated setups.

Thinking about buying a capsule filling machine in China? Well, doing a bit of a comparison between the top manufacturers really helps you make a smarter choice. Some of the main players you’ll come across are Guangzhou Dongsun, TSHS, and ACG Worldwide. Each of these brands offers something a little different — whether it's bigger machine capacities, more automation, or simpler maintenance. For example, Guangzhou Dongsun is known for its tough machines that are perfect if you're looking to produce loads of capsules, while TSHS tends to focus on making machines that are super user-friendly, so you don’t get bogged down with complicated setups.

Oh, and don’t forget to pay attention to what materials they’re using in these machines. The quality of materials like stainless steel really matters because it affects both the safety and longevity of the equipment. The good brands usually stick to high-grade stainless steel and meet international standards, so you know you’re getting a reliable, durable piece of equipment. Lastly, it’s worth considering what kind of customer support they offer too. A company that provides thorough training and quick, helpful technical support can make your life a whole lot easier, especially when you’re trying to keep things running smoothly.

All in all, doing your homework on these factors will help you choose the right machine that fits your needs — it’s all about balancing capacity, ease of use, quality materials, and reliable support.

Cost-Benefit Analysis: Investment in Capsule Filling Machines vs. Production Efficiency

When you're thinking about investing in capsule filling machines, it's helpful to do a cost-benefit check. Honestly, while a fancy, high-quality machine might cost more upfront, it often pays off in the long run thanks to faster filling speeds and better precision—all of which means you can get more done, more efficiently. So, take a moment to really look at your production needs and match them with the machine’s capabilities to make sure you're making the best call.

Quick tip: Before you buy anything, do some homework on suppliers in China. Ask for samples or even a demo if you can—seeing how the machine actually performs gives you a better idea of its reliability. Also, don’t forget to compare warranties and after-sales support; they’re really important for keeping things running smoothly down the line.

And honestly, don’t overlook the long-term savings. Less labor cost, less material waste—those little things add up. An automated filling machine doesn’t just cut down on human errors and keep quality consistent; it also boosts your overall efficiency and can even boost your company's reputation in the marketplace.

Another thing to keep in mind: keep an eye on the total cost of ownership, including maintenance and running costs. That way, you can really understand if the machine’s worth it for your specific setup. Setting some clear goals on what you want to improve can also help you see if your investment is paying off over time.

Maximize Efficiency in Your Supplement Business with the Ultimate Capsule Filling Machine

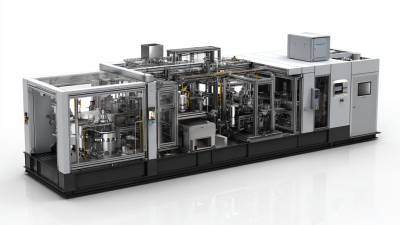

In today’s fast-paced pharmaceutical industry, efficiency is paramount, and investing in the right equipment can make all the difference. The Ultimate Capsule Filling Machine is designed to meet the dynamic needs of supplement businesses by streamlining the capsule filling process. With its unique combination of electrical and gas control, this machine operates with precision and reliability, ensuring that every capsule is filled accurately.

Equipped with an electronic automatic counting device, the machine not only enhances productivity but also reduces labor intensity significantly. It automates vital processes such as positioning, separation, filling, and locking of capsules, allowing businesses to scale their operations while maintaining high hygiene standards. The robust design of this filling machine ensures sensitivity in action, enabling it to adapt to various capsule types—both domestic and imported—making it a versatile addition to any supplement manufacturer’s arsenal.

Moreover, the aesthetic appeal and user-friendly operation of the Ultimate Capsule Filling Machine contribute to its overall appeal. It embodies the latest technological advancements in the pharmaceutical industry, making it the ideal choice for businesses looking to maximize their efficiency and elevate their production capabilities. Whether you are a small-scale operation or a large manufacturer, embracing this innovative machine can propel your supplement business to new heights.

FAQS

: Output capacity, measured in capsules per hour, is crucial as high-efficiency machines can produce over 40,000 capsules per hour, greatly enhancing productivity and reducing costs.

Automation features, such as automatic capsule sorting and filling, minimize human error and improve consistency, potentially increasing operational efficiency by up to 30%.

It's important to evaluate machine capacity, level of automation, ease of maintenance, materials used, and the quality of customer support provided by manufacturers.

The quality of materials, such as high-grade stainless steel, affects product safety and reliability, making it essential for manufacturers to comply with international quality standards.

Although the initial investment may be higher, high-quality machines lead to increased output, reduced labor costs, and minimized material waste, ultimately improving production efficiency.

Businesses should conduct thorough research on suppliers, request samples and demonstrations, and compare warranties and after-sales support to evaluate machine performance and reliability.

TCO includes all costs associated with the machine, such as maintenance and operating costs, helping businesses gauge the overall value and effectiveness of their investment over time.

Automated machines reduce human error and ensure consistent product quality, which enhances operational efficiency and improves the company's reputation in the market.

Adjustable dosage settings increase product versatility and compliance with Good Manufacturing Practices (GMP), making machines more efficient for varying production needs.

Setting clear goals for efficiency gains allows businesses to measure the effectiveness of their investment over time, ensuring they achieve desired improvements in production.

Related Posts

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

-

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

-

The Future of Efficient Cartridge Filling Machine Innovations

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

Blog Tags: