Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

Table of Contents

- Key Factors to Consider When Selecting an Automatic Filling Machine for Pharmaceuticals

- Understanding Different Types of Automatic Filling Machines and Their Suitability

- Assessing Production Capacity and Speed Requirements for Pharmaceutical Applications

- The Importance of Compliance with Regulatory Standards in Pharmaceutical Filling

- Evaluating Maintenance and Support Services for Long-term Machine Performance

- Cost Considerations: Balancing Quality and Budget in Your Machine Selection

- Optimizing Pharmaceutical Production: The Benefits of 30ml Glass Bottle Syrup Filling and Capping Machines

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing world of pharmaceuticals, picking the right equipment isn’t just a detail—it's actually a pretty big deal when it comes to making sure your products are top-notch and meet all the necessary rules. I was just reading a recent report by Grand View Research, and it looks like the global market for pharmaceutical filling machines could hit about $12.6 billion by 2025. A big part of that growth comes from the growing need for faster, more precise filling processes. If you’re in this game, you probably know Shanghai IVEN Pharmatech Engineering Co., Ltd.—they’re one of the big players in China, making automatic filling machines specifically for pharma. They’ve got four factories fully dedicated to pharma machinery, and they’re constantly pushing out new tech that meets the toughest industry standards. In this blog, I want to share some key points to think about when you're picking an automatic filling machine—something that can really help you stay ahead of the competition and keep your production on point.

Key Factors to Consider When Selecting an Automatic Filling Machine for Pharmaceuticals

So, when you're picking out an automatic filling machine for pharmaceutical use, there are a few important things you really want to keep in mind. These factors can make a big difference in how smooth your production runs, whether you're staying compliant, and just overall product quality. First off, you gotta check if the machine can handle different kinds of liquids—think about viscosity and formulations. Like, can it handle everything from sterile solutions to thick syrups? That’s super important.

And since safety and hygiene are such big deals in pharma, make sure you go for equipment that meets international standards and is easy to clean and maintain—because nobody wants headaches on that front.

Also, don’t forget about scalability. As your business grows or changes, your filling machine should be able to keep up. Having features like programmable settings or modular parts makes upgrades a whole lot easier down the line. We totally get these needs here at Shanghai IVEN Pharmatech Engineering Co., Ltd. — that’s why our automatic filling machines are crafted with top-notch precision and cutting-edge tech, so they can handle the tough demands of pharma production while keeping things running efficiently across our four specialized factories.

Understanding Different Types of Automatic Filling Machines and Their Suitability

When you're trying to pick the right automatic filling machine for pharmaceuticals, it’s pretty important to get a good grasp of the different types out there and what they’re best suited for. The market for sterile liquid filling machines is really on the rise — I mean, it’s expected to hit some pretty impressive numbers by 2032 — mainly because of how much it’s used in pharma. Now, among the various types of filling machines, you’ve got options like volumetric, piston, gravity, and pump fillers. Each one has its own perks, depending on what kind of product you’re dealing with. For example, piston fillers are perfect if you’re working with thicker, high-viscosity liquids. On the other hand, gravity fillers work best for thinner, less viscous solutions.

Another thing to think about is the filling speed. Machines come in different speeds—low, medium, and sometimes even higher—to match different production needs. Oh, and a recent report pointed out that the market for forming, filling, and sealing (or FFS) machines is growing too — expected to go over $8.7 billion by 2024. It’s growing at about 5.2% annually from 2025 to 2034. The main driver? The food and beverage industry’s demand for easy, hygienic packaging solutions, which really spills over into pharma as well. That means choosing the right machine isn’t just about efficiency — it’s also about meeting those strict industry regulations for safety and hygiene. Bottom line, picking the right filling machine can make a huge difference in how smooth your production runs, and how well you stay compliant with industry standards.

Assessing Production Capacity and Speed Requirements for Pharmaceutical Applications

So, when you're trying to pick the right automatic filling machine from China for your pharma operations, it’s really important to think about your production capacity and how fast you need things to go. Manufacturing medicines isn’t just about throwing products on a line; it’s about precision and efficiency—because the quality and effectiveness of your meds rely heavily on getting the filling just right. You’ve got to look at your current production goals, but also keep an eye on the future—growth is inevitable, right? Picking equipment that can handle your busy periods without missing a beat is key to keeping everything running smoothly and ensuring the medicine’s integrity isn’t compromised.

At Shanghai IVEN Pharmatech Engineering Co., Ltd., we totally get what the pharma industry needs. With four specialized factories committed to pharma machinery, we offer some of the best automatic filling machines out there. Whether your production volume is small or huge, we’ve got solutions tailored to match your speed and capacity needs. We’re not just about providing reliable equipment; we’re here to help you optimize your entire production process, making sure you stay compliant with all the strict industry standards while boosting efficiency and profitability. Basically, we’re your partners in making sure your production runs seamlessly—because we know how critical that is for your success.

The Importance of Compliance with Regulatory Standards in Pharmaceutical Filling

In the pharmaceutical world, following the rules isn’t just a suggestion — it’s absolutely essential for making sure that products are safe and actually work. I read that almost 70% of pharma companies ran into trouble because they didn’t fully comply with filling and labeling standards in the past year, according to the International Society for Pharmaceutical Engineering (ISPE). That really emphasizes why it’s so important to pick an automatic filling machine that ticks all the boxes. When choosing your equipment, you gotta make sure it sticks to Good Manufacturing Practice (GMP) guidelines, which are enforced by authorities like the FDA and EMA.

And let’s be honest, ignoring compliance can hit your wallet pretty hard. A Deloitte survey from 2022 showed that pharma companies end up spending around $1.2 million per product because of delays and fines caused by regulatory issues. That’s no small change. Luckily, modern automated filling machines with features like data tracking and in-line inspections can help avoid these costly problems. Investing in tech that keeps you compliant isn’t just about dodging penalties — it also boosts your reputation in this super competitive market, and let’s face it, that’s what we all want, right?

Evaluating Maintenance and Support Services for Long-term Machine Performance

When you're looking at automatic filling machines for pharma stuff, it's super important to check out the maintenance and support services. Trust me, this can make or break how well your machine performs long-term. Did you know, according to MarketsandMarkets, the global market for pharma packaging gear is expected to hit around $8.9 billion by 2025? That just goes to show how crucial reliable machinery has become. Plus, sticking to regular maintenance can cut down your downtime by up to 30%. That’s a huge deal when it comes to keeping things flowing smoothly.

A good tip? Always ask the manufacturer about their maintenance schedules and support options. If they offer solid service contracts that include things like preventive maintenance and quick repairs, you’re basically investing in peace of mind—and saving money in the long run. Having easy access to spare parts and tech support is also a game-changer. A Deloitte survey found that companies who build strong relationships with their equipment suppliers experience about 20% less unplanned downtime. So, it really pays to have support you can rely on when things go sideways.

Another thing to consider: Look for a supplier that provides proper training for your team on how to operate and maintain the machines. A well-trained crew can spot potential issues early on, stopping costly breakdowns before they happen and helping your equipment last way longer.

Cost Considerations: Balancing Quality and Budget in Your Machine Selection

When you're choosing an automatic filling machine for pharmaceutical work, it’s really important to think about the costs involved. Sure, going for the cheapest option might seem like a good idea at first, but honestly, you gotta consider what you’re sacrificing in terms of quality and efficiency down the line. Sometimes, a machine that seems like a bargain upfront can end up causing hassles later—maybe it doesn’t fully meet regulatory standards or doesn’t run as smoothly as you’d like, which can end up costing you more in the end. So, the key is to find that sweet spot between quality and budget. You want a machine that ticks all the industry boxes but also makes financial sense in the long run.

At Shanghai IVEN Pharmatech Engineering Co., Ltd., we totally get that balance. That’s why we’ve got a diverse lineup of pharmaceutical equipment. With four specialized factories, we produce all the top-tier filling machines, blood collection tube machinery, and water treatment systems you might need. Our goal is to give our clients high-quality gear without breaking the bank. By investing in our advanced equipment, pharmaceutical companies can boost productivity, stay compliant with strict industry standards, and ultimately, enjoy better profitability and lasting success. It’s all about making smart choices that work for your business in the long run.

Optimizing Pharmaceutical Production: The Benefits of 30ml Glass Bottle Syrup Filling and Capping Machines

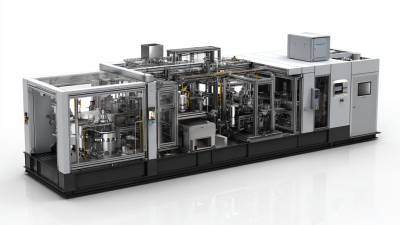

The pharmaceutical industry is constantly evolving, and optimizing production processes is essential to meeting the growing demand for quality products. One significant advancement in this realm is the introduction of specialized 30ml glass bottle syrup filling and capping machines. The IVEN Syrup Filling and Capping Machine exemplifies this innovation, integrating multiple functions to enhance efficiency and hygiene. The machine comprises an ultrasonic washing system, a drying and sterilizing unit, and the filling and capping mechanism, ensuring that each bottle meets stringent health standards.

According to a recent industry report, the global syrup market is projected to grow at a CAGR of 4.2% from 2023 to 2030. This increases the need for reliable filling technology, especially for smaller doses used in syrups and other liquid formulations. The IVEN machine not only provides precise filling capabilities but is also adaptable to various bottle sizes and types, making it a versatile choice for pharmaceutical manufacturers. Additionally, with optional features such as air charging and drying, the system can be tailored to specific production needs, significantly reducing the risk of contamination and improving production timelines.

The incorporation of a labeling machine into the IVEN solution creates a seamless production line, essential for maintaining compliance in the pharmaceutical sector. Efficient labeling is critical, given that proper identification directly affects patient safety. As the demand for high-quality syrup products continues to rise, investing in advanced equipment like IVEN’s filling and capping machine can lead to substantial operational improvements and contribute to sustained growth in the industry.

FAQS

: It's crucial to evaluate the machine’s capability to handle various types of liquids, including differing viscosities and formulations like sterile solutions and viscous syrups.

Safety and hygiene standards are paramount in the pharmaceutical industry, so it is essential to choose machines that comply with strict international regulations and include easy cleaning and maintenance features.

Scalability is very important as production needs may evolve; a flexible system that can adapt to changing volumes and product varieties is essential.

Features such as programmable settings and modular designs should be sought to facilitate future upgrades in the machine.

It's important to understand that while initial savings may be appealing, the long-term impacts on quality and efficiency should be considered to avoid future higher costs.

A balance can be achieved by ensuring that the chosen machine meets stringent industry requirements while also being a sound financial investment, avoiding the temptation to simply choose the lowest price option.

Shanghai IVEN Pharmatech Engineering Co., Ltd. offers a diverse range of high-quality pharmaceutical machinery designed to enhance productivity while maintaining compliance with industry standards.

Investing in advanced equipment can boost productivity and help maintain compliance with industry standards, ultimately leading to greater profitability and sustained success in operations.

Conclusion

When you're looking to pick out a China Automatic Filling Machine for your pharma projects, there are quite a few important things you should keep in mind. It’s really helpful to understand the different types of automatic filling machines out there and figure out which ones are best suited for your specific pharmaceutical products. Plus, thinking about the production speed and capacity you need will help ensure the machine can keep up with your demands. Of course, sticking to all the regulatory standards is a must — nobody wants to compromise safety or product quality.

Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we get how important these factors are. That’s why we offer top-notch filling machines that meet all industry regulations. Don't forget, it’s also worth looking into the maintenance support you’ll get — a reliable service team makes a big difference in keeping everything running smoothly in the long run. And finally, finding a good balance between quality and what fits your budget will really help you make a smart, confident choice for your pharmaceutical filling needs.

Related Posts

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

Blog Tags: