Ultimate Checklist for Selecting the Right Vial Filling Equipment

Table of Contents

- Key Factors to Consider When Choosing Vial Filling Equipment

- Types of Vial Filling Machines: Which One is Right for You?

- Reviewing the Best Vial Filling Equipment Brands in the Market

- Cost vs. Performance: Finding the Perfect Balance in Vial Fillers

- Essential Features to Look for in Automated Vial Filling Systems

- Assessing Maintenance and Support for Your Vial Filling Equipment

- Maximizing Efficiency in Industrial Processes: The Role of Online Dilution and Dosing Equipment

- FAQS

- Conclusion

- Related Posts

Hey there! You know, in the fast-paced world of pharma, picking the right vial filling equipment isn't just a small decision anymore — it's pretty crucial. Manufacturers really have to get it right if they want to keep up with strict regulations and, of course, ensure their products are top-notch.

I recently came across a market report that says the global pharma packaging market, which covers stuff like vial filling machines, is expected to grow at about 8.1% annually. That really shows how much demand there is for reliable and efficient packaging solutions these days.

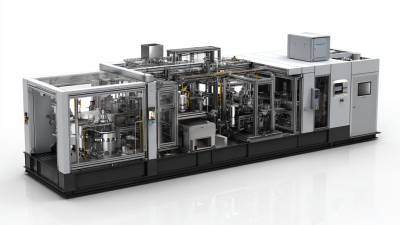

Companies like Shanghai IVEN Pharmatech are leading the charge with cutting-edge tech — they’ve got four dedicated factories making everything from advanced machinery for pharmaceuticals, blood collection tubes, to water treatment systems. As this market keeps growing, it’s super important for businesses to understand what features to look for and consider when choosing vial filling equipment. That way, they can stay efficient, competitive, and ready for whatever the future holds.

Hey there! You know, in the fast-paced world of pharma, picking the right vial filling equipment isn't just a small decision anymore — it's pretty crucial. Manufacturers really have to get it right if they want to keep up with strict regulations and, of course, ensure their products are top-notch.

I recently came across a market report that says the global pharma packaging market, which covers stuff like vial filling machines, is expected to grow at about 8.1% annually. That really shows how much demand there is for reliable and efficient packaging solutions these days.

Companies like Shanghai IVEN Pharmatech are leading the charge with cutting-edge tech — they’ve got four dedicated factories making everything from advanced machinery for pharmaceuticals, blood collection tubes, to water treatment systems. As this market keeps growing, it’s super important for businesses to understand what features to look for and consider when choosing vial filling equipment. That way, they can stay efficient, competitive, and ready for whatever the future holds.

Key Factors to Consider When Choosing Vial Filling Equipment

When you're picking out vial filling equipment, there are a few important things to keep in mind to make sure everything runs smoothly and meets industry standards. First off, it’s really key that the equipment can handle different vial sizes and materials—nobody wants to be stuck with machines that only work for one thing. I read somewhere that the global market for vial filling machines is expected to jump from about $1.21 billion in 2020 to around $1.56 billion by 2025, which shows how much companies are looking for versatile machinery that can adapt to different specs. That kind of flexibility doesn’t just mean you can fill a wider range of products, but it also helps boost your overall production capacity.

Another big factor is the technology behind the filling process. Nowadays, automated systems—especially those using aseptic techniques—are pretty much a must-have in pharma. According to a report from Grand View Research, the market for aseptic filling is forecasted to grow at a yearly rate of about 9.6% between 2021 and 2028. Automation not only reduces human error but also cuts down on contamination risks, which is super important for compliance and keeping product quality up. Also, you wanna think about how fast the machine can fill vials (its throughput rate) and how easy it is to clean—these things can really make a difference in how quickly and efficiently you can get your work done. So, keeping these technical aspects in mind when choosing your equipment is really crucial for running a successful vial filling operation.

Types of Vial Filling Machines: Which One is Right for You?

When you're trying to pick out the right vial filling machine, it’s really helpful to get a handle on the different types out there. Basically, you’ve got three main options: manual, semi-automatic, and fully automatic. Manual machines are great if you’re just starting out or working on a small scale—they’re usually more budget-friendly and super flexible when it comes to handling different vial sizes. But keep in mind, they do rely on skilled operators, and they tend to be a bit slower compared to the automated types.

Then there are semi-automatic machines, which kinda sit in the middle. They bump up efficiency but still need some human oversight. These machines usually handle the filling part automatically but you'll still need to supervise other things like capping and labeling. And finally, for big production runs, fully automatic vial filling machines are the way to go. They’re built for continuous, high-volume work and require minimal hands-on effort. Many of these come with pretty neat features like inline inspection systems and integrated labeling, making them perfect for bigger companies that need precision and scalability.

At the end of the day, choosing the right machine really depends on what you’re looking to achieve, your budget, and the specific needs of your products. By weighing the pros and cons of each type, you’ll be able to find the perfect fit for your operation and goals. It’s all about matching the machine to what you actually need to get done, without overdoing it.

Reviewing the Best Vial Filling Equipment Brands in the Market

The pharmaceutical packaging equipment market is really heating up these days, especially with all the cool new vial filling machines coming out. If you're in the industry, you know how important it is to pick the right equipment — it can make a huge difference in how smoothly your production runs and whether you stay compliant with all the regulations. Oh, and there’s this exciting sneak peek at a new robotic vial filling machine happening at a major conference. It’s a clear sign that automation and precision are taking center stage in this space.

When you're trying to choose your vial filling equipment, here are a few things worth keeping in mind:

First off, check out the technical specs. You want machines that can handle different vial sizes, materials, and types — basically, something flexible enough to match whatever products you have in the pipeline.

Next up, pay attention to the brand’s reputation. Going with trusted manufacturers that stand behind their gear is key. It really influences your day-to-day efficiency and how quickly you can get support if things go wrong.

And don’t forget about scalability. Aim for equipment that can grow with your business. You don’t want to keep buying new machines every time demand picks up — look for options that can adapt without needing a complete overhaul.

Things are moving fast in this market, so staying in the loop about the latest brands and tech developments really helps you make smarter choices tailored to your production needs.

Cost vs. Performance: Finding the Perfect Balance in Vial Fillers

When you're choosing vial filling equipment, finding that sweet spot between cost and performance is super important if you want to streamline your production. Investing in good-quality machines that boost efficiency can actually save you money down the line. But here’s the thing—picking the most expensive model doesn’t always mean you’ll get the better results you're after. So, it’s really worth taking the time to compare each option's features and reliability against your budget.

Tip 1: Before you pull the trigger, do a thorough cost-benefit analysis. Don’t just think about the upfront price; consider long-term stuff too—like maintenance costs and possible downtimes. That way, you’ll get a clearer picture of what your actual investment is worth.

Tip 2: Try to find equipment that’s customizable or flexible enough to handle different vial sizes and types. This kind of versatility can save you from buying multiple machines later on, which is a big plus when balancing cost versus performance for your specific production needs.

If you keep these points in mind, you'll be better equipped to find vial filling equipment that fits your needs without going over budget. It’s all about making smart choices that pay off in the long run.

Essential Features to Look for in Automated Vial Filling Systems

Picking the right vial filling equipment is a really big deal in the pharma world, especially now with the huge surge in demand for biologic drugs. These days, automated filling systems are pretty much a must-have. When you're trying to choose what to go with, it's good to pay attention to a few key features that make sure everything runs smoothly and the quality stays top-notch.

First off, think about how well the system keeps everything sterile and maintains high quality during the filling. It's a smart move to look for equipment that uses the latest digital and automation tech — these can really boost how consistent and quick your process is, plus help get better yields. For example, systems with user-friendly controls and precise automation make switching between different vial types or sizes way easier and quicker.

On top of that, you'll want to check if the equipment has solid leak testing features. These days, there are automatic leak testers designed to meet the tough standards of pharma production. They’re super important because they help ensure that the vials stay sterile and contamination-free, keeping the product safe for patients. In the end, focusing on these features will give you reliable, efficient filling operations that you can count on.

Assessing Maintenance and Support for Your Vial Filling Equipment

When you're choosing vial filling equipment, it’s super important to look at maintenance and support. After all, you want your operation to run smoothly and keep the quality of your products top-notch. Did you know that the global market for fill finish manufacturing is booming? It’s expected to jump from around $12 billion in 2025 to over $25 billion by 2030. That really shows how critical it is to invest in equipment that not only performs well but also comes with solid support and maintenance options.

One key thing is preventive maintenance. Regular checkups and repairs can make a huge difference — they help keep your machines reliable and performing at their best. Studies show that taking a proactive approach can significantly boost efficiency in manufacturing environments. By setting up a routine for inspections and fixing issues early, you minimize downtime and maintain consistent quality, especially in sensitive fields like biologics where cleanliness and precision are everything.

Plus, it’s a smart move to use data-driven monitoring tools. These tech-savvy methods give you real-time info about your equipment’s health, so you can fix problems before they turn into costly breakdowns. In today’s world, where product quality directly impacts patient health, giving maintenance and support top priority is absolutely crucial for ensuring a smooth vial filling process — and ultimately, success.

Ultimate Checklist for Selecting the Right Vial Filling Equipment - Assessing Maintenance and Support for Your Vial Filling Equipment

| Parameter | Importance Level | Maintenance Frequency | Support Availability | Additional Notes |

|---|---|---|---|---|

| Ease of Maintenance | High | Monthly | 24/7 Support | User-friendly manuals available |

| Spare Parts Availability | Medium | Quarterly | Business Hours | Parts typically in stock |

| Technical Support Quality | High | As Needed | Email & Phone | Highly rated by users |

| Training Services Offered | Medium | Annually | Scheduled Sessions | On-site and online options available |

| Warranty Period | High | N/A | N/A | Comprehensive warranty terms |

Maximizing Efficiency in Industrial Processes: The Role of Online Dilution and Dosing Equipment

In the biopharmaceutical industry, the downstream purification process is crucial for ensuring the quality and efficacy of therapeutic proteins. A significant aspect of this process is the preparation of buffers, which must be both accurate and reproducible. Recent studies have shown that even slight variations in buffer composition can lead to suboptimal purification results, affecting yield and purity. For instance, a report by the International Society for Pharmaceutical Engineering highlights that inconsistencies in buffer preparation can decrease overall purification efficiency by up to 30%.

To tackle this challenge, the implementation of online dilution and dosing equipment has emerged as a game changer. This technology allows for the seamless combination of various single-component buffers, ensuring that the mother liquor and diluent are mixed online to achieve the desired target solution. Such systems not only improve the precision of preparation but also enhance workflow efficiency. According to a recent market analysis by MarketsandMarkets, the demand for automated dosing systems in biopharmaceutical applications is expected to grow at a CAGR of 10.1% from 2022 to 2027, underscoring the industry's shift toward more advanced and reliable solutions.

By optimizing the buffer preparation process through online dilution and dosing systems, biopharmaceutical manufacturers can significantly improve their purification processes. These innovations not only reduce manual labor but also mitigate human error, allowing for greater consistency and reliability in the production of high-quality biopharmaceuticals. With the growing emphasis on efficiency and effectiveness in industrial processes, adopting such technologies is not just beneficial—it is essential for maintaining a competitive edge in the market.

FAQS

: The three primary types of vial filling machines are manual, semi-automatic, and fully automatic. Manual machines are suited for small operations, semi-automatic machines provide a balance of efficiency and operator involvement, and fully automatic machines are designed for high-output production with minimal manual intervention.

Manual vial filling machines are cost-effective and flexible, making them ideal for small-scale operations or startups. However, they require skilled operators and generally have slower production rates compared to automated machines.

Semi-automatic machines automate the filling process but still require operator supervision for tasks like capping and labeling, offering a middle ground between manual and fully automatic systems.

When selecting vial filling equipment, evaluate technical specifications for flexibility, assess brand reputation for reliability, and focus on scalability to accommodate increasing production demands.

Fully automatic vial filling machines enable high-output operations with advanced features such as in-line inspection and integrated labeling, making them ideal for larger manufacturers who prioritize scalability and precision.

Essential features include the ability to maintain sterility, advanced digitalization and automation for improved efficiency, and robust leak testing capabilities to ensure product safety and integrity.

Digitalization enhances repeatability and speed in vial filling processes, and systems with intuitive controls allow for quicker transitions between different vial types and sizes.

Leak testing is crucial in ensuring the integrity of sterile vials, preventing contamination, and ensuring product safety, which is especially important in the pharmaceutical sector.

The vial filling equipment market is seeing a trend towards automation and improved precision, exemplified by the upcoming introduction of robotic vial filling machines at industry conferences.

Conclusion

When you're picking out the right vial filling equipment, it’s important to consider a few key things to make sure everything runs smoothly and efficiently. Things like how big your production is, how precise the fill volume needs to be, and what kind of liquid you're working with can really impact your choice. Getting to know the different types of vial filling machines—whether they're manual, semi-automatic, or fully automated—can help you figure out what’s the best fit for your operation. Plus, it’s worth looking into different brands and balancing costs with performance so you end up with something reliable that fits your budget without sacrificing quality.

Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we get it—features like user-friendliness, flexibility, and solid maintenance support are super important when it comes to automated vial filling systems. Our team’s got a ton of expertise in pharmaceutical machinery, so we’re confident we can help you find the perfect equipment tailored to your needs. And we’re always committed to quality and good service. By keeping these things in mind, you'll set yourself up for a smooth, efficient vial filling process that really boosts your production capacity.

Related Posts

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

-

Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

Blog Tags: