How to Choose the Best Aseptic Capping Machines for Your Packaging Needs

Table of Contents

- Factors to Consider When Choosing Aseptic Capping Machines

- Types of Aseptic Capping Machines Available on the Market

- Understanding the Importance of Aseptic Packaging Standards

- Evaluating Production Capacity Requirements for Capping Machines

- Key Features to Look for in Aseptic Capping Machines

- Assessing Maintenance and Support for Capping Equipment

- Budgeting for Aseptic Capping Machines: Costs and Financing Options

- FAQS

- Conclusion

- Related Posts

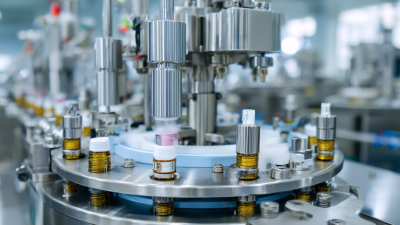

When it comes to making sure your products stay safe and last as long as they should, picking the right Aseptic Capping Machine is a pretty big deal for manufacturers in the food and beverage world. Dr. Emily Thompson, who’s a big name in packaging tech at the Institute of Food Packaging Innovation, really stresses how important this decision is: 'The reliability and efficiency of these machines directly impact your product’s quality and how much your customers trust them.' As companies try to keep up with all the changing rules and what consumers want these days, choosing the right machine definitely deserves some serious thought.

Aseptic Capping Machines don’t just help keep perishable stuff fresh longer — they can also make the whole production process run smoother. With all the tech advancements, there are so many options out there it can get kinda overwhelming. It’s super important to think about things like how automated the machine is, how easy it is to maintain, and whether it’ll play nicely with your existing setup. At the end of the day, understanding what you really need in your packaging will point you toward the best choice. This way, you can make sure your products stay safe, look good, and keep your customers happy.

Factors to Consider When Choosing Aseptic Capping Machines

When selecting the best aseptic capping machines for your packaging needs, several key factors must be taken into account to ensure optimal performance and efficiency. First, consider the type of products you will be packaging. Aseptic capping machines vary in their capabilities, such as handling different bottle types and sizes, as well as accommodating various closure types. Understanding the specifications required for your product can help streamline the selection process and avoid compatibility issues.

Another crucial factor is the automation level of the capping machine. Fully automated machines can significantly improve production speed and reduce labor costs. However, semi-automated systems might be more suitable for smaller operations or those with varying product lines. It's essential to evaluate your production volume and future scalability when deciding on the automation features.

Types of Aseptic Capping Machines Available on the Market

When selecting an aseptic capping machine for your packaging needs, it's important to understand the various types available on the market. Aseptic capping machines can be broadly categorized into several types, each designed to meet specific requirements of different packaging processes. For instance, some machines are designed for high-speed production, capable of handling thousands of bottles per hour, making them ideal for large-scale bottling operations. Other machines focus on versatility, capable of capping various container sizes and types, thus providing flexibility for businesses with diverse product lines.

Another key type of aseptic capping machine is the induction cap sealer, which employs electromagnetic induction to securely seal containers. This method not only ensures the sterility of the contents but also offers a tamper-proof seal that enhances product safety. Additionally, there are machines equipped with advanced features like automated cap feeding systems and integrated inspection technologies, ensuring that every container is properly sealed and ready for distribution. As businesses assess their options, understanding these types can greatly influence their decision, allowing them to choose a solution that perfectly aligns with their operational needs and product specifications.

Understanding the Importance of Aseptic Packaging Standards

Aseptic packaging standards play a critical role in ensuring the safety and quality of food and pharmaceutical products. According to a report by the International Society for Beverage Technologists, approximately 80% of foodborne illnesses can be traced back to improper packaging techniques. Aseptic capping machines are designed to address these challenges by creating a sterile environment where products can be filled and sealed without exposure to contaminants. This process is essential for maintaining the integrity of products, especially those with a prolonged shelf life, such as juices, dairy, and ready-to-eat meals.

Compliance with aseptic standards can significantly affect the marketability and consumer trust in products. The Global Aseptic Packaging Market is projected to reach USD 71.4 billion by 2026, growing at a CAGR of 10.4% from 2021 to 2026, as reported by Mordor Intelligence. This growth is largely driven by increasing demand for extended shelf life products and stringent food safety regulations. To capitalize on this trend, manufacturers must understand the specific aseptic packaging standards applicable in their regions, which often dictate the technologies and machinery used in production lines. Investing in the right aseptic capping machines is not just a matter of regulatory compliance; it is a critical factor in ensuring product safety and enhancing brand reputation in a competitive marketplace.

How to Choose the Best Aseptic Capping Machines for Your Packaging Needs - Understanding the Importance of Aseptic Packaging Standards

| Machine Type | Speed (BPM) | Aseptic Standards Compliance | Maintenance Frequency | Price Range (USD) |

|---|---|---|---|---|

| Automatic Capping Machine | 200 | ISO 22000 | Monthly | $20,000 - $30,000 |

| Semi-Automatic Capping Machine | 120 | HACCP | Quarterly | $10,000 - $15,000 |

| Handheld Capping Tool | 30 | No Specific Standard | As Needed | $500 - $2,000 |

| Inline Capping Machine | 150 | GMP | Monthly | $15,000 - $25,000 |

Evaluating Production Capacity Requirements for Capping Machines

When selecting aseptic capping machines for your packaging needs, it is crucial to evaluate your production capacity requirements accurately. Aseptic packaging is gaining traction due to its ability to extend the shelf life of products without refrigeration, thus understanding the production needs becomes essential. According to a report by Smithers Pira, the global market for aseptic packaging is expected to reach $52 billion by 2024, which reflects an increasing demand for efficient and high-capacity capping solutions.

Different production capacities influence not only the selection of the capping machine but also its configuration. For instance, if your operational goal is producing 1000 units per hour, you will need a machine that can support that output seamlessly while maintaining sterile conditions. It is advisable to align the capping machine's capacity with the daily production target. Many manufacturers recommend opting for machines with a slightly higher capacity than your current requirement, anticipating future growth.

**Tips:** Before making a purchase, analyze your current packaging speed and evaluate future efficiency goals. Additionally, consider the machine's flexibility to adapt to changing production volumes and product types; versatility can save both time and investment costs in the long run. Engaging with industry experts to assess the specific requirements and seeking data-driven insights can also aid in making an informed decision.

Key Features to Look for in Aseptic Capping Machines

When selecting an aseptic capping machine, it's essential to focus on key features that ensure the efficiency, safety, and reliability of your packaging process. One critical aspect is the machine's sealing technology, which should provide a robust barrier against microbial contamination. Look for machines equipped with advanced sealing mechanisms that maintain the integrity of the product while ensuring that sterility is preserved throughout the packaging process.

Another important feature to consider is the machine’s compatibility with various container types and sizes. This flexibility allows for seamless adaptation to different production needs, making it easier to switch between product lines without extensive downtime. Additionally, features such as automated adjustments and easy-to-use interfaces can enhance operational efficiency and reduce the likelihood of human error during the capping process. Investing in a machine with these characteristics will ultimately optimize productivity and uphold the standards of quality and safety necessary for aseptic packaging.

Assessing Maintenance and Support for Capping Equipment

When selecting an aseptic capping machine, assessing maintenance and support is crucial to ensure optimal performance and longevity of the equipment. According to a recent industry report by MarketsandMarkets, the global demand for aseptic packaging is projected to grow from $55 billion in 2021 to over $77 billion by 2026, emphasizing the importance of reliable capping solutions. Regular maintenance intervals not only enhance machine efficiency but also minimize downtime, which can lead to significant cost savings in manufacturing processes.

Tips: Invest in training for your staff to understand the maintenance needs of your capping machines. This will enable them to identify potential issues before they escalate, ensuring uninterrupted production. Furthermore, check manufacturer warranties and service agreements to secure timely support and spare parts.

Moreover, consider the availability of technical support from the manufacturers. As the aseptic packaging industry becomes increasingly technology-driven, having access to a knowledgeable support team can make all the difference. According to a study by PMMI, 61% of companies stated that technical assistance played a vital role in choosing their packaging equipment. Ensure that your chosen machine comes with comprehensive documentation and a robust support structure to facilitate troubleshooting and repairs.

Budgeting for Aseptic Capping Machines: Costs and Financing Options

When considering the acquisition of aseptic capping machines, one of the most critical factors to address is budgeting. The costs associated with these machines can vary significantly based on features, production capacity, and level of automation. Businesses should start by conducting thorough research to create a detailed budget that encompasses not only the purchase price but also ongoing operational costs such as maintenance, training, and potential upgrades. It’s important to balance quality and cost, ensuring that the chosen machine meets both current and future packaging needs while fitting into the financial framework of the business.

Financing options are another key aspect to explore when budgeting for aseptic capping machines. Many suppliers offer flexible payment plans or leasing options, which can ease the immediate financial burden. Businesses may also consider financing through banks or specialized lenders who understand the manufacturing sector, potentially providing loans with favorable terms. It’s essential to evaluate all available financing strategies, making sure to select one that aligns with the company's cash flow and production demands, enabling a smooth implementation of the new machinery without compromising operational efficiency.

Cost Comparison of Aseptic Capping Machines by Type

FAQS

: Key factors include the type and size of products being packaged, the level of automation needed, ease of maintenance and cleaning, and the availability of technical support and spare parts.

Fully automated machines increase production speed and reduce labor costs, making them suitable for high-volume operations, while semi-automated systems may be better for smaller operations or varying product lines.

Advanced sealing technology ensures a robust barrier against microbial contamination, preserving product integrity and sterility throughout the packaging process.

Features such as compatibility with various container types, automated adjustments, and user-friendly interfaces can reduce downtime and minimize human error.

Start by researching the purchase price, ongoing operational costs, maintenance, training, and potential upgrades to create a comprehensive budget that meets both current and future needs.

Many suppliers offer flexible payment plans or leasing options, and businesses may also explore financing through banks or specialized lenders for favorable loan terms.

Regular maintenance is crucial for preventing downtime and ensuring consistent machine performance, especially in aseptic environments that require high hygiene standards.

Machines that can easily accommodate various container types and sizes allow for seamless transitions between different product lines, enhancing overall production efficiency.

Essential research areas include machine specifications, features that align with production needs, budget considerations, and the reliability of available technical support.

Conclusion

When selecting the best Aseptic Capping Machines for your packaging needs, several crucial factors must be considered. It's essential to evaluate the types of machines available, their production capacity requirements, and the importance of adhering to aseptic packaging standards. Understanding the key features, such as speed, efficiency, and ease of operation, can significantly impact your packaging process. Additionally, assessing maintenance and support options is vital for ensuring longevity and reliability in your production line.

Budgeting for Aseptic Capping Machines involves considering the costs of equipment and potential financing options. A well-thought-out selection process not only enhances operational efficiency but also ensures compliance with industry standards, making your investment worthwhile. By carefully navigating these aspects, you'll be better equipped to choose the right Aseptic Capping Machines that align with your business goals.

Related Posts

-

The Future of Pharmaceutical Safety: Revolutionary Aseptic Capping Machines Explained

-

How Vial Filling Machines Revolutionize the Pharmaceutical Industry: A Closer Look

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

Ultimate Checklist for Selecting the Right Vial Filling Equipment

-

Exploring the Future of Bioreactor Manufacturers: Innovations Shaping Biotechnology in 2024

-

Exploring the Latest Innovations in Vial Filling Equipment for Enhanced Efficiency

Blog Tags: