What is Efficient Blister Production and How It Transforms Pharmaceutical Packaging

Table of Contents

- Understanding Efficient Blister Production in Pharmaceutical Packaging

- Key Technologies Driving Efficiency in Blister Production

- Benefits of Streamlined Blister Packaging for Pharmaceuticals

- Challenges and Solutions in Blister Production Processes

- Future Trends in Blister Packaging and Pharmaceutical Innovation

- FAQS

- Conclusion

- Related Posts

You know, in the ever-changing world of pharma packaging, 'Efficient Blister Production' really stands out as a game-changer. It’s all about making sure medicines are both safe and effective when they reach us. According to the latest market reports, the global blister packaging market is expected to hit around $36.5 billion by 2026, growing at roughly 5.5% each year. This surge is mostly because folks want better drug protection and easier usability.

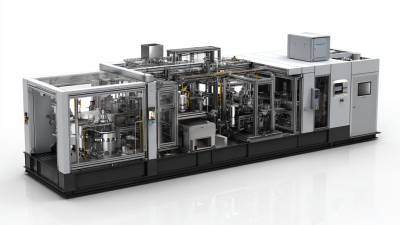

Shanghai IVEN Pharmatech is right there in the mix, leading the charge with some pretty awesome machinery that makes the whole blister packaging process smoother and faster. They've got four main factories dedicated to making pharmaceutical equipment, including high-tech blister packers, so they’re really set up to meet industry demands for both speed and accuracy. By pouring into new tech, IVEN not only boosts production but also makes sure everything stays compliant with regulations. That way, medicines get to us safely and efficiently. Pretty exciting, right?

Understanding Efficient Blister Production in Pharmaceutical Packaging

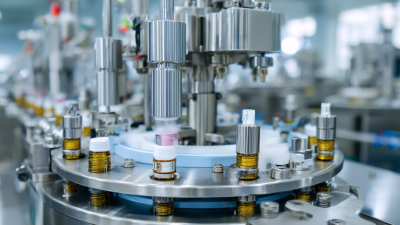

Getting efficient blister production right is a real game-changer for pharma packaging. It’s all about making sure medications are presented well and kept safe from the elements. Basically, these sealed packs protect tablets and capsules from humidity, air, and other environmental stuff, helping them stay stable longer and last longer on shelves. As demand for medicines keeps climbing, understanding how to streamline blister production can really make a difference—cutting down on waste and boosting the reliability of your products.

Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we're all about providing top-notch machinery that supports these smart, efficient packaging methods. With four factories dedicated to pharmaceutical equipment, we focus on innovative solutions tailored to the industry’s needs. By blending good design with solid manufacturing, we help pharma companies perfect their packaging processes—so their products stay safe and effective all the way from production to the patient.

Efficient Blister Production in Pharmaceutical Packaging

Key Technologies Driving Efficiency in Blister Production

These days, there's really a shift happening in how blister production is changing the game in pharma packaging. It's all about using some pretty cutting-edge tech to make the whole process smoother and the final products more consistent. One big thing helping out is automation — I mean, companies are jumping on this bandwagon fast.

According to a report from Research and Markets, the global market for automated blister packaging is projected to hit $3.23 billion by 2025, growing at a compound annual growth rate (CAGR) of around 6.4% since 2020. What’s awesome about automation? Well, it cuts down on cycle times, reduces errors that humans might make, and allows for real-time oversight of the entire production process. All this stuff together really boosts efficiency and keeps quality control tight.

Another game-changer is the rise of smart packaging that leverages IoT tech. Basically, these solutions let manufacturers keep tabs on the product conditions right during production and storage — no more guessing if things are going okay in the back. Deloitte even points out that companies using IoT in their packaging lines can cut waste by as much as 30%. Plus, these smart blister packs can monitor things like humidity and temperature, helping to make sure the meds stay stable and work effectively. That’s a huge plus for patient safety and adherence, especially in today’s focused environment on traceability and meeting strict regulations. All these innovations do more than just speed things up — they also help pharma companies stay compliant and keep track of everything easily, which is super important these days.

Benefits of Streamlined Blister Packaging for Pharmaceuticals

You know, efficient blister production really has turned into a total game-changer in the world of pharmaceutical packaging. It brings a bunch of benefits that actually matter to both the companies making the stuff and the folks using it. The whole process is now way smoother — it cuts down on production time and even improves the quality and safety of the packaging. I came across this report from Smithers PIRA that says the global market for blister packaging is expected to hit about $29 billion by 2025. That’s mainly because there's a growing demand for packaging that's not just quick and cheap but also tamper-proof and user-friendly — you know, to keep meds safe and secure.

Plus, adopting the latest tech and machinery has really upped the game in terms of efficiency. For example, companies that use automation in their lines are seeing scrap rates drop by as much as 20%, which adds up to pretty big savings. And get this — these automated systems make switching between different products way faster, cutting down on downtime and boosting output. All this stuff doesn’t just benefit the supply chain; it also helps companies meet strict regulatory standards, making sure that medicines stay safe and effective from the moment they're packaged all the way to when they're in your hands.

Challenges and Solutions in Blister Production Processes

Getting blister production just right is pretty key in the pharma world. After all, it's all about making sure meds are safely and effectively packaged. That said, it’s not always smooth sailing — there are some hurdles to watch out for. One biggie? The inconsistency in material quality. Sometimes, the materials used can vary, which might mess with the strength of the blisters and could even put patient safety at risk. It’s super important that these materials meet strict industry standards because, honestly, any slip-up could have serious consequences for folks relying on these medications.

Getting blister production just right is pretty key in the pharma world. After all, it's all about making sure meds are safely and effectively packaged. That said, it’s not always smooth sailing — there are some hurdles to watch out for. One biggie? The inconsistency in material quality. Sometimes, the materials used can vary, which might mess with the strength of the blisters and could even put patient safety at risk. It’s super important that these materials meet strict industry standards because, honestly, any slip-up could have serious consequences for folks relying on these medications.

Then there's the balancing act of keeping things speedy and efficient while still making sure every blister pack is up to snuff in terms of quality. To handle that, companies are turning to tech like automated inspection tools and real-time monitoring systems. These upgrades can really help bump up production speed and also keep safety in check. By tackling these challenges with modern tech, blister manufacturing can get way more reliable and efficient — which means better packaging and, ultimately, safer medications for everyone.

Future Trends in Blister Packaging and Pharmaceutical Innovation

Looking ahead, the future of blister packaging in the pharma world is pretty exciting and full of innovation. Companies are really pushing for stuff that's not just efficient but also eco-friendly. These days, we're seeing more smart packaging solutions popping up — like those with RFID and NFC tech built right into the blister packs. They can give real-time info on whether patients are actually taking their meds, and manufacturers get a better peek into what consumers want. Pretty cool, right?

If you're into optimizing blister production, switching to automated processes is a no-brainer. It cuts down on mistakes and boosts efficiency. Plus, using greener materials, like biodegradable plastics or recycled stuff, is gaining popularity — folks are definitely more conscious about the environment now. Partnering up with tech firms to bring in digital printing and customization can really tailor products to specific patient needs, making everything more personalized.

And let’s not forget the importance of creating packs that are both child-resistant and accessible for seniors. Making sure these packs are secure but also easy enough to open can really make a difference in patient satisfaction. Overall, as things keep evolving in pharma, hopping on these trends will be key for companies wanting to stay ahead — delivering better packaging solutions while keeping up with regulations and what consumers expect.

FAQS

: Efficient blister production involves creating sealed packs that protect tablets and capsules from environmental factors, ensuring stability and extending shelf life.

Automation reduces cycle times, minimizes human error, and enables real-time monitoring of production processes, improving operational efficiency and product consistency.

Smart packaging solutions with IoT capabilities allow for real-time tracking of product conditions, which can reduce waste and enhance drug stability by monitoring factors like humidity and temperature.

The global automated blister packaging market is expected to reach $3.23 billion by 2025, growing at a CAGR of 6.4% from 2020.

It reduces production time, improves quality and safety, and allows for faster product changeovers, leading to lower scrap rates and cost savings.

The global blister packaging market is projected to reach $28.98 billion by 2025, driven by demand for efficient, cost-effective, tamper-resistant, and user-friendly packaging solutions.

Advanced machine technologies enhance operational efficiency, reduce scrap rates by up to 20%, and improve supply chain dynamics while ensuring regulatory compliance.

Streamlined methods ensure medication integrity, leading to better patient adherence and safety, by providing tamper-resistant and user-friendly packaging solutions.

Compliance ensures that pharmaceuticals are packaged to safeguard their efficacy and safety throughout their lifecycle, meeting stringent regulatory standards.

Efficient blister production enhances packaging operations, reduces waste, improves product reliability, and aligns with the industry's focus on quality and safety.

Conclusion

Efficient blister production is a really important part of today's pharmaceutical packaging scene. It’s what helps manufacturers stay on top of quality and follow all the necessary regulations. The cool part? They’re using some pretty advanced tech now—things that make the whole process smoother, faster, and cut down on waste. You’ll see lots of automation, smart design choices, and materials that last longer and keep medicines fresh longer. As the pharma world keeps changing, the perks of good blister packaging are pretty obvious—like saving money and keeping patients safer.

That said, getting to a point where blister production runs so efficiently isn’t always straightforward. There’re issues like equipment limitations and tricky regulations to sort out. That’s where companies like Shanghai IVEN Pharmatech come in—they really know their stuff when it comes to pharmaceutical machinery and tech, and they help sort through these hurdles. Looking ahead, all the new trends and innovations in blister packaging are likely to shake things up even more, making packaging more sustainable and efficient than ever before.

Related Posts

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Understanding the Essentials of Automated Filter Tube Production Techniques

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

Understanding the Functionality and Benefits of a Dry Filling Machine in Modern Industries

-

The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

Blog Tags: