Ultimate Guide to Efficient Glas Bottle Packaging Machines for Your Production Line

Table of Contents

- Benefits of Implementing Glass Bottle Packaging Machines in Your Production Line

- Key Features to Look for in Efficient Glass Bottle Packaging Equipment

- Top Strategies for Optimizing Your Bottle Packaging Process

- Understanding the Cost-Effectiveness of Advanced Packaging Solutions

- Common Challenges in Glass Bottle Packaging and How to Overcome Them

- Future Trends in Glass Bottle Packaging Technology for Increased Efficiency

- Optimizing Pharmaceutical Production: The Benefits of a Glass Bottle IV Solution Production Line

- FAQS

- Conclusion

- Related Posts

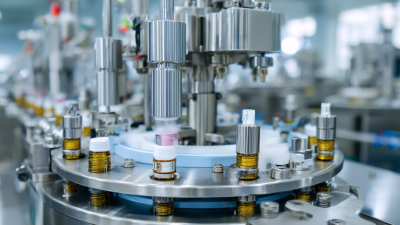

In the fast-moving world of manufacturing, staying efficient—especially when it comes to packaging—is a total must. That’s where Glas Bottle Packaging Machines really come in. They offer some pretty cool, innovative solutions that make the whole packaging process smoother and help bump up productivity. Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we totally get just how important these machines are across different industries—pharmaceuticals included—where precision and dependability are absolutely critical. We’ve got four highly skilled factories focused on pharmaceutical machinery, blood collection tubes, and water treatment equipment, so you can count on us to provide top-quality Glas Bottle Packaging Machines tailored to your production line needs. In this comprehensive guide, we’ll dive into the key features, the main benefits, and some best practices to help you make the most out of these advanced machines and keep your packaging running as efficiently as possible.

Benefits of Implementing Glass Bottle Packaging Machines in Your Production Line

Adding glass bottle packaging machines to your production line can really make a difference—especially if you're in industries like pharma or food & beverage. I came across a report from MarketsandMarkets that said the global packaging machinery market is expected to jump from about $43.7 billion back in 2020 to around $60.5 billion by 2025. That's a pretty solid growth rate of roughly 6.8% per year. Part of what’s driving that growth is how modern glass bottle packaging solutions are making things smoother and more reliable—helping companies not just ramp up production but also improve overall product quality.

But it’s not just about speed. Using glass bottle packing equipment actually helps keep products safer and extends their shelf life. Glass is non-reactive, so it’s great for keeping products like medicines in top shape. The International Society for Pharmaceutical Engineering (ISPE) also pointed out that glass reduces contamination risks, which is a big deal when you’re trying to meet international standards. Companies like Shanghai IVEN Pharmatech are offering specialized machinery tailored for different needs, so businesses can hit their quality targets without sacrificing efficiency. As more folks look for sustainable packaging options, investing in reliable glass bottle packaging systems really becomes a no-brainer if you want to stay competitive out there.

Key Features to Look for in Efficient Glass Bottle Packaging Equipment

When you're shopping around for glass bottle packaging machines, there are a few key features that can really make a difference in how smoothly your production runs. So, I came across this report from Smithers Pira, and it kind of blew my mind — it says that automated packaging machines can bump up your output by up to 30%. Plus, they help cut down labor costs and cut down on those human errors we all dread. Honestly, one of the most important things to look for is automated bottle handling. Think systems that sort, fill, and cap bottles all in sync with your schedule — it just makes everything so much more effortless.

And, since technology’s moved forward so much, having vision systems for quality control is a total game-changer. These systems can spot products that don’t meet standards before they get packed, which is pretty cool. A study by Technavio even mentions that using this kind of tech can slash product defects by up to 25%. Oh, and don’t forget about modular design. It’s super handy because as your needs change or grow, you can tweak or expand your setup without needing to buy a whole new machine. Basically, picking packaging equipment with these features isn’t just about keeping things running — it’s about making your whole operation run more smoothly and efficiently.

Top Strategies for Optimizing Your Bottle Packaging Process

When you're looking to optimize your bottle packaging process, one thing's for sure—efficiency really makes a big difference. A good starting point is investing in high-quality glass bottle packaging machines that fit your specific production needs. These machines should come with features like automated filling, capping, and labeling—these can seriously cut down on manual work and help avoid human errors. Oh, and choosing machines with adjustable settings is a smart move because it means you can easily handle different bottle sizes and shapes without much hassle, making your whole line way more flexible.

Another thing to keep in mind is adding smart tech into your system. Using data analytics and IoT-enabled machines can give you real-time insights into how things are running. That way, you can quickly spot any hiccups or bottlenecks and fix them on the fly. It’s a proactive approach that not only boosts efficiency but also helps you produce a higher quality product. And don’t forget about regular maintenance—keeping your equipment in good shape prevents unexpected downtime and keeps everything running smoothly. All these little changes, when put together, can really ramp up your bottling operation, helping you hit your production targets while still maintaining top-notch quality for your glass bottles.

Ultimate Guide to Efficient Glass Bottle Packaging Machines

| Machine Type | Speed (Bottles/Minute) | Power Consumption (kW) | Dimension (L x W x H, mm) | Key Feature |

|---|---|---|---|---|

| Automatic Filling Machine | 120 | 5.5 | 2500 x 800 x 2000 | Easy-to-Clean Design |

| Labeling Machine | 150 | 2.0 | 1800 x 600 x 1800 | Smart Sensor Detection |

| Bottle Capping Machine | 100 | 3.5 | 2000 x 700 x 1800 | Adjustable Torque Control |

| Packaging Machine | 80 | 4.0 | 2200 x 800 x 2000 | Film Wrapping System |

Understanding the Cost-Effectiveness of Advanced Packaging Solutions

When you're thinking about jazzing up your production line, it’s pretty important to get a handle on how cost-effective those fancy packaging solutions are — especially when it comes to glass bottle machines. Honestly, investing in newer, smarter machines isn’t just about making things run smoother; it can seriously save you a ton of money over time. These machines are built to cut down on wasted materials and lower labor costs, all while keeping productivity high. It’s like getting the best of both worlds.

Pro tip: Take some time to really analyze your whole setup. Look for any bottlenecks or areas where things slow down or get messy. Pinpoint where those high-tech glass bottle packers could fit in for the biggest boost. Doing this kind of review can help you spot the smartest investments—those that give you the biggest bang for your buck.

Plus, with tech nowadays, you’ve got machines that can adapt to different production needs. That kind of flexibility is a game-changer—it means you can ramp up or dial things down without totally overhauling your setup. This way, your operations stay smooth, and costs stay predictable.

Another tip: Check out modular machines—that’s a fancy way of saying machines that can be reconfigured or expanded as your needs change. This kind of adaptability not only saves you money on new gear down the line but also keeps your packaging process efficient as your business grows and shifts. It’s all about staying nimble and making smart choices along the way.

Common Challenges in Glass Bottle Packaging and How to Overcome Them

In the fast-paced world of FMCG, dealing with glass bottle packaging isn't always straightforward. Manufacturers often run into issues like the glass being super fragile, which means handling has to be really careful—no rushing! To tackle this, many companies are turning to automated packaging machines. These tech-savvy systems can really boost efficiency and cut down on the chances of breakage during packing. Plus, investing in such advanced equipment helps streamline the whole process, lowers labor costs, and keeps the supply chain running smoothly.

Another thing to keep in mind is making sure that the packaging isn’t just practical, but also eco-friendly. The industry’s moving towards recyclable materials, which is a great shift but also adds a layer of challenge. Collaborating with suppliers who prioritize sustainability becomes more important than ever. Using innovative materials and smarter packaging techniques not only makes the product look better but also helps brands stick to environmental standards. Take Shanghai IVEN Pharmatech Engineering Co., Ltd., for example—they’re showing how investing in efficient, green solutions can really help brands stay competitive in this busy FMCG scene.

Future Trends in Glass Bottle Packaging Technology for Increased Efficiency

As the beverage and pharmaceutical worlds keep growing, there's a real buzz around finding faster and smarter ways to package products in glass bottles. According to some recent industry reports, we're looking at up to a 30% jump in packaging efficiency over the next five years thanks to new automation and smarter tech. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are leading the charge with specialized machinery that’s pretty much tailored for all kinds of packaging needs—whether it’s for medicine or food-grade stuff.

If you’re looking to boost your own efficiency, a good tip is to invest in high-speed glass bottle packers that come with AI-powered data analysis. This kind of tech doesn’t just speed things up; it helps minimize waste by keeping a close eye on everything happening on the line. Plus, using innovative materials for your bottles can really cut down on weight, which means lower shipping costs and less energy used during production.

And here’s a pretty exciting trend—more companies are jumping on the sustainability bandwagon. Consumers are actually caring more about eco-friendly products than ever, pushing brands to adopt recyclable and reusable packaging options. This not only helps the planet but also aligns with global green goals. Shanghai IVEN Pharmatech is super dedicated to staying ahead of the curve, making sure their machinery isn’t just meeting today’s standards but also paving the way for future innovations in glass bottle packaging.

Glass Bottle Packaging Efficiency Trends

Optimizing Pharmaceutical Production: The Benefits of a Glass Bottle IV Solution Production Line

The pharmaceutical industry continually seeks ways to enhance efficiency and ensure product quality, and an effective solution lies in the adoption of glass bottle IV solution production lines. These specialized systems are designed for the comprehensive processing of glass bottles ranging from 50 to 500ml, streamlining essential functions like washing, depyrogenation, filling, stoppering, and capping. This optimization not only increases production speed but also significantly reduces the risk of contamination, which is crucial in maintaining the integrity of intravenous solutions.

Utilizing a glass bottle IV solution production line enables manufacturers to produce a diverse array of medical liquids, including glucose, antibiotics, amino acids, fat emulsions, nutrient solutions, and various biological agents. Each stage of production is meticulously controlled, ensuring that every solution adheres to the highest safety and quality standards. The ability to efficiently produce these essential medical fluids in a robust glass container adds a layer of reliability that enhances patient care, especially in critical treatment scenarios. Investing in such a production line is not just about keeping up with industry standards; it's about setting them and delivering superior solutions for healthcare providers.

FAQS

: Key features to look for include automated bottle handling, advanced quality control technologies such as vision systems, and modular design for flexibility and scalability.

Automated packaging machinery can boost output by up to 30%, reduce labor costs, and minimize the risk of human error.

Quality control systems, like vision systems, ensure that only products meeting quality standards proceed to packaging, potentially decreasing product defects by up to 25%.

Modular design allows for flexibility and scalability, enabling the system to adapt as production needs grow or change without requiring complete replacement.

To optimize the process, invest in high-quality machines with functionalities like automated filling, capping, and labeling, and choose machines with adjustable settings for various bottle sizes and shapes.

Smart technology, including data analytics and IoT-enabled machines, allows for real-time monitoring to identify bottlenecks and address issues promptly, which improves operational efficiency and product quality.

Regular maintenance of packaging equipment is essential to prevent downtime and ensure a streamlined workflow, leading to increased output and cost savings.

Investing in efficient packaging equipment allows for a more streamlined operation that meets production goals while maintaining the quality of glass products.

Automated filling and capping reduce manual labor and the risk of human error, contributing to a more efficient and reliable packaging process.

Yes, machines with adjustable settings can accommodate a variety of bottle sizes and shapes, ensuring versatility in the production line.

Conclusion

You know, in today’s super competitive market, having reliable Glas Bottle Packaging Machines in your production line can really make a difference—boosting your overall efficiency and productivity. These machines come with some pretty great perks: faster speeds, better accuracy, and more consistent packaging, which is a big win. When you're choosing the right equipment, it’s all about looking out for features like automation and flexibility—you want machinery that can keep up and adapt to your needs. Plus, understanding the costs involved and how advanced packaging options can save you money in the long run is totally worth it. Addressing common issues early on can also help you manage resources better and cut down on downtime.

Looking ahead, it’s pretty clear that keeping tabs on the latest trends in Glas Bottle Packaging tech is key to staying ahead of the game. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are leading the charge, offering specialized machines that cater to the changing demands of industries like pharma and water treatment. Investing in the right packaging equipment isn’t just about solving today’s problems — it’s about making your business more adaptable and efficient for whatever the future throws your way.

Related Posts

-

The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

Blog Tags: