Top 10 Tips for Efficient Injection Pen Assembly Line Setup and Optimization

Table of Contents

- Injection Pen Assembly Line Overview and Importance

- Assessing Current Assembly Line Efficiency

- Key Components of Injection Pen Assembly Process

- Best Practices for Assembly Line Layout and Design

- Implementing Automation and Technology in the Assembly Line

- Training and Workforce Management for Optimal Performance

- Continuous Improvement Strategies for Assembly Line Optimization

- Optimizing Efficiency and Quality in Cartridge Filling Production Line Operations

- FAQS

- Conclusion

- Related Posts

The pharma industry is constantly evolving, and one of the hot topics right now is making manufacturing processes more efficient—especially when it comes to producing injection pens. These assembly lines are absolutely crucial for getting medical devices out on time without sacrificing quality. And if you look at the numbers, it’s pretty impressive—the global injection pen market is expected to hit around $43.3 billion by 2027. That’s a steady growth rate of about 8.1% year over year from 2020 to 2027, according to Fortune Business Insights. All this growth basically screams one thing: manufacturers really need to fine-tune their assembly processes if they want to keep up with demand while still keeping standards high.

Getting your injection pen assembly line set up smartly can make a huge difference—not just in boosting productivity but also in cutting down on costs. There was a study from the Lean Enterprise Institute that showed applying lean manufacturing principles to assembly lines can improve efficiency by up to 30%. As the healthcare landscape keeps changing fast, it’s more important than ever for companies to adopt best practices and innovative strategies in managing their assembly lines. In this article, I’ll share the top 10 tips for setting up a really effective injection pen assembly line—practical insights that can help your team increase both output and quality, without the hassle.

Injection Pen Assembly Line Overview and Importance

The assembly line for injection pens plays a crucial role in the medical device manufacturing sector. It not only ensures the efficient production of quality products but also impacts patient safety and satisfaction. A well-structured assembly line moves components through various stages of assembly seamlessly, reducing time and minimizing errors. Understanding the importance of this assembly line is vital for quality assurance and workflow maximization in the production process.

To achieve an efficient setup, start by streamlining the workflow. Ensure that each workstation is ergonomically designed for optimal worker productivity, allowing employees to perform tasks with minimal strain. Implementing lean manufacturing principles can also help eliminate waste and enhance the overall efficiency of the assembly line.

Additionally, invest in proper training for the workforce. Well-trained employees will be better equipped to identify issues quickly and maintain quality standards. Regular feedback loops can encourage ongoing improvements in the process, ensuring the assembly line remains adaptive and responsive to production needs. By focusing on these strategies, companies can significantly boost their assembly line's effectiveness and maintain high-quality output in injection pen manufacturing.

Assessing Current Assembly Line Efficiency

Assessing the current efficiency of an injection pen assembly line is fundamental to achieving optimal productivity and quality. To begin this assessment, a comprehensive analysis of the workflow is crucial. This involves mapping out every step of the assembly process to identify bottlenecks or redundancies that may hamper production. By utilizing time-motion studies, managers can quantify how long each task takes and pinpoint stages that require streamlining. Additionally, evaluating worker performance through metrics can uncover training or staffing needs, ensuring that each team member is functioning at peak capability.

Another vital aspect of this assessment is examining the equipment and technology utilized in the assembly line. Understanding whether the machinery is up-to-date and functioning properly can have a significant impact on efficiency. Regular maintenance and timely upgrades can prevent unexpected downtimes and enhance operational speed. Furthermore, exploring automation opportunities may present innovative solutions that optimize repetitive tasks, allowing human resources to focus on quality control and other critical functions. By prioritizing both workflow analysis and equipment efficiency, manufacturers can establish a solid foundation for ongoing optimization efforts.

Key Components of Injection Pen Assembly Process

The injection pen assembly process involves several key components that are crucial for ensuring both efficiency and quality. Central to this process are the injection molded parts, which must be precisely manufactured to meet specific regulatory standards. Additionally, each assembly line should include stations for component inspection, assembly, and quality control testing. This systematic approach not only enhances productivity but also minimizes the risk of defects in the final product.

To optimize your assembly line setup, consider implementing the first tip: streamline the component flow. Organizing workstations logically and minimizing unnecessary movement can significantly improve the speed of assembly. Another essential tip is to invest in automation where feasible. Utilizing automated systems for repetitive tasks can free up skilled labor for more complex assembly operations, ultimately enhancing overall efficiency. Regular training for assembly line workers on best practices and updates in techniques can also contribute to a smoother operation and higher quality outcomes.

Best Practices for Assembly Line Layout and Design

Effective assembly line layout and design are critical components in optimizing the efficiency of injection pen production. A well-structured layout not only minimizes production time but also enhances worker safety and reduces the likelihood of errors. According to a report from the International Society of Automation, facilities with optimized layouts can achieve a 30% increase in productivity by reducing the amount of time workers spend moving between stations. Key design principles, such as implementing a U-shaped layout, allow for better communication and collaboration among team members, further streamlining the workflow.

Incorporating lean manufacturing techniques also plays a vital role in the assembly line design. By limiting waste and focusing on value-added activities, manufacturers can significantly improve their overall operational efficiency. A study by the Lean Enterprise Institute highlights that organizations that embrace lean principles often see a reduction in lead times by up to 50%. Additionally, integrating ergonomic workstations aids in reducing worker fatigue and improving job satisfaction, resulting in lower turnover rates and consistent quality in pen assembly. Overall, prioritizing an efficient assembly line layout not only boosts productivity but also contributes to a more sustainable manufacturing environment.

Implementing Automation and Technology in the Assembly Line

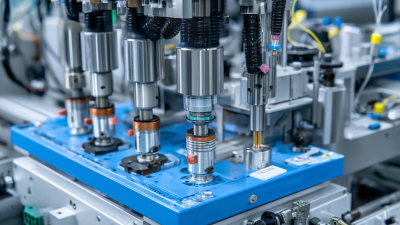

In the rapidly evolving landscape of manufacturing, the integration of automation and technology into injection pen assembly lines has become essential for enhancing efficiency and output. A recent report from the International Society for Automation indicates that companies leveraging automation technologies experience an average productivity increase of 20-25%. Implementing automated assembly systems, such as robotic arms and conveyor systems, not only speeds up production but also reduces the margin for error that manual assembly processes often incur. By employing precision engineering through advanced robotics, manufacturers can ensure consistent quality and compliance with stringent industry standards.

Moreover, the adoption of Industry 4.0 principles, including the Internet of Things (IoT) and real-time data analytics, plays a crucial role in optimizing assembly line workflows. According to a study by McKinsey & Company, businesses that adopt smart factory technologies are projected to realize a reduction in operational costs by up to 30%, significantly enhancing their competitive edge. Real-time monitoring allows for swift decision-making and efficient resource allocation, ensuring that delays at any stage of the production process can be promptly addressed. By incorporating these advanced technologies, injection pen assembly lines not only meet market demands more effectively but also adapt swiftly to changing consumer needs, setting the stage for sustained growth in a dynamic industry.

Training and Workforce Management for Optimal Performance

Effective training and workforce management are critical components of setting up and optimizing an injection pen assembly line. Investing in thorough training programs ensures that all staff are equipped with the necessary skills to operate machinery efficiently and adhere to quality standards. Regular training sessions, coupled with hands-on experience, can significantly enhance the team's capability to manage various challenges that arise during the production process.

One tip for optimizing performance is to create a detailed training manual that outlines best practices and operational procedures specific to the injection pen assembly line. This guide should be easily accessible and regularly updated to reflect any changes in processes or technology. Additionally, fostering a culture of continuous improvement, where employees are encouraged to share insights and suggest enhancements, can lead to a more engaged workforce and better operational outcomes.

Another vital tip is to implement a mentorship program that pairs experienced workers with newer team members. This not only accelerates the learning curve for new hires but also strengthens team cohesion and knowledge transfer within the workforce. Cross-training employees in various roles can also contribute to greater flexibility and efficiency, enabling the assembly line to adapt more quickly to production demands.

Continuous Improvement Strategies for Assembly Line Optimization

The assembly line for injection pen manufacturing is a complex process that requires careful optimization to enhance efficiency and productivity. Continuous improvement strategies, grounded in methodologies like Lean and Six Sigma, play a pivotal role in achieving this goal. A recent industry report indicates that companies implementing Lean principles can achieve productivity improvements of up to 25%, while Six Sigma initiatives can lead to a 50% reduction in defects. These methodologies encourage a culture of ongoing assessment and refinement, ensuring that slow steps in the process are identified and addressed.

Additionally, investing in training and development for assembly line workers is crucial. Research indicates that organizations that prioritize employee training can see labor efficiency rise by an impressive 20% to 40%. Empowering workers with the skills to identify inefficiencies and encourage innovative problem solving not only optimizes the assembly line but also fosters a proactive working environment. Moreover, utilizing data analytics to monitor production metrics can enhance decision-making processes, leading to quicker adjustments and improved workflow. Regular evaluations using these strategies can significantly bolster both speed and quality in the assembly of injection pens, ultimately contributing to higher customer satisfaction and reduced time-to-market.

Top 10 Tips for Efficient Injection Pen Assembly Line Setup and Optimization

| Tip No. | Tip Description | Expected Outcome | Implementation Difficulty |

|---|---|---|---|

| 1 | Standardize processes across the assembly line. | Improved consistency and reduced variability. | Medium |

| 2 | Implement lean manufacturing principles. | Reduction in waste and increased efficiency. | High |

| 3 | Utilize automation technologies where applicable. | Increased speed and reduced labor costs. | High |

| 4 | Regularly train assembly line workers. | Higher skill level and adaptability. | Medium |

| 5 | Optimize workspace layout for efficiency. | Minimized movement and increased productivity. | Low |

| 6 | Incorporate real-time monitoring tools. | Improved oversight and quicker issue identification. | High |

| 7 | Establish clear performance metrics. | Better measurement of productivity and success. | Medium |

| 8 | Foster a culture of continuous improvement. | Engaged workforce and ongoing enhancements. | Medium |

| 9 | Implement a pull system to manage inventory. | Reduced inventory costs and waste. | High |

| 10 | Conduct regular reviews and adjustments. | Ensured alignment with goals and project changes. | Low |

Optimizing Efficiency and Quality in Cartridge Filling Production Line Operations

The efficiency and quality in cartridge filling production line operations play a crucial role in ensuring the seamless production of cartridges and carpules. Implementing state-of-the-art technologies in filling processes enhances the overall output while maintaining high standards of safety and reliability. Modern production lines are designed to perform key functions including bottom stoppering, liquid vacuuming to remove surplus liquid, cap adding, and capping after drying and sterilizing. Each of these steps is critical in delivering a finished product that meets stringent quality requirements.

Additionally, the integration of intelligent control systems significantly optimizes production processes. These systems feature full safety detection mechanisms that prevent production errors, such as no cartridge or carpule present, which stops the stoppering and filling processes automatically. This not only reduces wastage but also enhances operational efficiency by ensuring that materials are fed automatically when supplies run low. Such technological advancements not only streamline operations but also contribute to a more sustainable production environment, where quality is not compromised.

FAQS

: Assessing the efficiency of an assembly line is crucial for achieving optimal productivity and quality. It helps identify bottlenecks, redundancies, and areas needing improvement in the workflow.

Time-motion studies can be utilized to measure how long each task takes and to pinpoint stages requiring streamlining for better efficiency.

Evaluating worker performance through metrics can reveal training or staffing needs, ensuring that each team member operates at peak capability, thereby enhancing overall efficiency.

The condition and functionality of machinery significantly affect efficiency. Regular maintenance and timely updates can help avoid downtimes and improve operational speed.

Automation can optimize repetitive tasks, allowing workers to focus on quality control and other critical functions, thereby increasing overall efficiency.

Implementing a U-shaped layout and focusing on lean manufacturing principles can enhance communication, reduce production time, and minimize waste, leading to increased productivity.

By limiting waste and emphasizing value-added activities, lean manufacturing can significantly reduce lead times and improve overall operational efficiency.

Ergonomic workstations help reduce worker fatigue and improve job satisfaction, leading to lower turnover rates and maintaining consistent quality in assembly processes.

Optimized assembly line layouts can achieve productivity increases of up to 30% by minimizing the time workers spend moving between stations.

Prioritizing an efficient assembly line layout not only enhances productivity but also fosters a safer and more sustainable manufacturing environment.

Conclusion

The "Top 10 Tips for Efficient Injection Pen Assembly Line Setup and Optimization" provides a comprehensive guide for improving the production efficiency of injection pen assembly lines. It begins by highlighting the importance of a well-organized assembly line and assesses current efficiency levels to identify areas for enhancement. Key components of the injection pen assembly process are explored, alongside best practices for optimal layout and design to minimize waste and improve workflow.

Additionally, the article emphasizes the role of automation and technology in streamlining operations, while stressing the significance of training and workforce management to ensure optimal performance. Finally, it advocates for continuous improvement strategies to sustain efficiency gains over time. By implementing these tips, manufacturers can significantly enhance their injection pen assembly line operations, leading to better productivity and product quality.

Related Posts

-

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

-

7 Essential Tips for Choosing the Right Blow Fill Seal Manufacturers for Your Business

-

How to Maximize Production Efficiency with an IV Cannula Making Machine: A Data-Driven Approach

-

Top 10 Essential Pharmaceutical Packaging Equipment for Enhanced Efficiency

-

How to Choose the Right Syringe Filter Manufacturers for Your Laboratory Needs

-

How to Optimize Production Efficiency with a Single Dose Packaging Machine

Blog Tags: