Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

Table of Contents

- Emerging Trends in Vial Cap Sealing Technology: A Market Overview

- Key Features of High-Precision Vial Cap Sealers in Pharmaceutical Manufacturing

- Comparative Analysis of Cap Sealing Alternatives: Cost-Effectiveness and Efficiency

- Global Market Demand for Vial Cap Sealing Machines: Statistical Insights

- Innovations Driving the Future of Vial Cap Sealing: Sustainability and Automation

- Regulatory Standards Impacting Vial Cap Sealing Machine Design and Usage

- Transforming Oncology Manufacturing: Insights from the OEB5 Injectable Oncology Vial Turnkey Plant and Industry Market Reports

- FAQS

- Related Posts

Lately, the Vial Cap Sealing Machine Market has really been on the rise, mainly because there's a growing need for reliable and efficient packaging solutions in the pharma world. Just a quick heads-up from MarketsandMarkets—they’re saying that by 2027, the global pharma packaging market might hit a staggering USD 1 trillion! And within all that, vial cap sealing tech is pretty much the unsung hero, making sure products stay safe and intact.

Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we’re right in the thick of things, with four specialized factories dedicated to manufacturing top-notch pharmaceutical machinery, including some pretty advanced vial cap sealers. We’re all about pushing boundaries—delivering innovative sealing solutions that not only meet strict regulatory standards but also help our partners boost their efficiency. As the industry keeps evolving, we're committed to staying ahead of the curve with cutting-edge tech that supports the ever-growing needs of pharma companies worldwide.

Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we’re right in the thick of things, with four specialized factories dedicated to manufacturing top-notch pharmaceutical machinery, including some pretty advanced vial cap sealers. We’re all about pushing boundaries—delivering innovative sealing solutions that not only meet strict regulatory standards but also help our partners boost their efficiency. As the industry keeps evolving, we're committed to staying ahead of the curve with cutting-edge tech that supports the ever-growing needs of pharma companies worldwide.

Emerging Trends in Vial Cap Sealing Technology: A Market Overview

The world of vial cap sealing technology is changing pretty fast these days. It’s all about making things more efficient and sterile, especially in pharma and biotech, you know? Recently, we've seen some cool innovations like automated sealing machines. These gadgets not only cut down on the need for someone to do everything manually but also greatly lower the chances of contamination — pretty important, right? Thanks to newer materials and precision engineering, these machines do a stellar job at sealing properly, keeping products stable and safe during storage and transport.

One of the exciting trends right now is adding smart tech to these sealing machines. Features like real-time monitoring and data analytics are helping manufacturers keep a close eye on quality, catch issues early, and fine-tune their production. Plus, there's a big push toward being environmentally friendly, with new sealing solutions made from recyclable materials and designed to use less energy. As these trends grow, industries stand to gain a lot — better productivity, lower costs, and more trust from consumers who want to feel confident about the safety and effectiveness of what they’re buying.

Emerging Trends in Vial Cap Sealing Technology (2023)

This chart displays the market share of different vial cap sealing technologies across various regions, highlighting the innovative advancements that are shaping the industry.

Key Features of High-Precision Vial Cap Sealers in Pharmaceutical Manufacturing

In the world of pharma manufacturing, high-precision vial cap sealing machines really are a big deal. They're essential for making sure products stay safe and intact. I recently came across a report from Grand View Research that says the global market for these sealers is expected to hit around $1.5 billion by 2027, with a solid growth rate of about 6.4% annually. The main driver? The rising demand for pharmaceuticals and biologics, which need super reliable sealing to keep contamination at bay and make sure everything works as it should.

What’s pretty cool about these machines is their high-tech features. They use advanced sealing tech that greatly reduces leaks and contamination—crucial for meeting strict regulatory standards. Many modern sealers come with sensors and feedback systems that keep an eye on pressure and temperature during sealing, giving operators real-time info. According to MarketsandMarkets, these smart solutions, especially with IoT (Internet of Things) capabilities, help make manufacturing more efficient and cut down on unplanned downtime thanks to predictive maintenance.

Plus, these machines are pretty versatile — they can handle different vial sizes and materials, which is a huge plus in today’s market where personalized medicines are becoming more popular. As Mordor Intelligence points out, with more folks dealing with chronic diseases, pharma companies are looking for more flexible production options. All this just underscores how important innovative vial cap sealing tech is in the global pharma scene today.

Comparative Analysis of Cap Sealing Alternatives: Cost-Effectiveness and Efficiency

The global market’s really heating up with more demand for efficient and budget-friendly vial cap sealing machines. You know, Shanghai IVEN Pharmatech Engineering Co., Ltd. is pretty well-known for its expertise in pharma equipment, and they’re always pushing out innovative tech that’s setting new standards. They’ve got four dedicated factories—so it’s not just talk—they actually cover a bunch of areas like blood collection tube machinery and water treatment systems, making sure they have top-quality facilities to meet different customer needs.

When you're thinking about options for cap sealing, it’s really important to look at more than just the upfront costs. Long-term efficiency matters too. Some of these advanced machines come with automation and high precision tech, which can really cut down on labor costs and reduce product waste—pretty neat, right? It’s all about finding the right balance between initial investment and how well the machine performs day-to-day.

A few tips for choosing the right cap sealing machine? Think about its sealing speed, whether it works well with different vial sizes, and if it can adapt to your future production needs. Basically, taking the time to compare what each machine offers can help you make smarter choices—leading to better productivity and higher profits down the line.

Global Market Demand for Vial Cap Sealing Machines: Statistical Insights

Hey, so here's the scoop — the global market for vial cap sealing machines is really on the rise. A big driver behind this is the increasing demand for more sustainable packaging options. Industry reports are pointing out that between 2023 and 2030, we're looking at a solid growth rate of about 8.5% annually. People are definitely shifting toward eco-friendly materials and smarter tech, mainly because regulations are pushing companies to recycle more and cut down on plastic waste. No surprise there — everyone’s trying to do their part!

On top of that, the booming pharma and biotech sectors are also pushing up the need for these sealing machines. As of 2023, the global pharmaceutical packaging market is sitting around $160 billion, with a good chunk of that going into advanced sealing solutions. It’s all about safety and making sure the drugs work as intended, so reliable sealing is more important than ever. Companies that focus on creating efficient, eco-friendly sealing tech are pretty much set to ride this wave and find some pretty exciting growth opportunities ahead.

Innovations Driving the Future of Vial Cap Sealing: Sustainability and Automation

In the fast-changing world of pharmaceutical manufacturing, things like sustainability and automation have become super important if you're aiming for success. At Shanghai IVEN Pharmatech Engineering Co., Ltd., we’re really proud of how we’re pushing the envelope with our advanced vial cap sealing machines. These machines are pretty amazing — not only do they help make our operations smoother and more efficient, but they also cut down on environmental impact, fitting right into the global push for sustainability. We use the latest tech to make the sealing process more streamlined, which means less waste and less energy used — all while maintaining top-notch quality and safety standards.

Automation is really at the heart of what we do. It allows manufacturers to improve their production lines with a lot less manual effort. Our vial cap sealing machines come with smart features that let you monitor and tweak things on the fly, boosting productivity without sacrificing precision. Moving forward, we’re all about giving global markets solutions that tackle the current challenges in pharmaceutical manufacturing. Our goal? Help our clients keep up with shifting consumer needs while still staying true to sustainability and operational excellence. We believe that by staying innovative and adaptable, we can make a real difference in the industry.

Regulatory Standards Impacting Vial Cap Sealing Machine Design and Usage

So, when it comes to vial cap sealing machines, their design and how we actually use them are being shaped a lot by changing regulations—especially with all the concerns around the environment and safety. You know, with that new rule coming into effect by July 2024, which says plastic caps need to stay attached to single-use beverage bottles, manufacturers are really feeling the pressure to come up with smarter solutions. The goal? Make these machines easier to use, while also helping cut down on plastic waste. It’s kind of a blessing in disguise, actually — a chance to get creative and develop designs that fit both sustainability and compliance.

And then, if you look at the pharma world, the need for keeping injectable drugs sterile is more important than ever. We’re seeing cool advancements, like isolator-based fill and finish lines, which really focus on keeping everything aseptic during packaging. As regulators keep tightening the rules around pharmaceutical packaging, it’s clear that manufacturers of vial cap sealing machines need to step up—adding sturdy features that ensure sterility and stop contamination in its tracks. These new innovations don’t just check the boxes for compliance; they actually push the industry forward, setting higher standards for safety and reliability in such a heavily regulated market.

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

| Vial Cap Sealing Machine Model | Production Capacity (Vials/Min) | Sealing Technology | Compliance Standards | Market Applications |

|---|---|---|---|---|

| Model A | 300 | Heat Sealing | ISO 9001, GMP | Pharmaceuticals, Biotech |

| Model B | 250 | Ultrasonic Sealing | CE, ISO 13485 | Cosmetics, Food |

| Model C | 400 | Vacuum Sealing | FDA, GMP | Pharmaceuticals, Research |

| Model D | 350 | Induction Sealing | ISO 9001, CE | Food, Beverage |

Transforming Oncology Manufacturing: Insights from the OEB5 Injectable Oncology Vial Turnkey Plant and Industry Market Reports

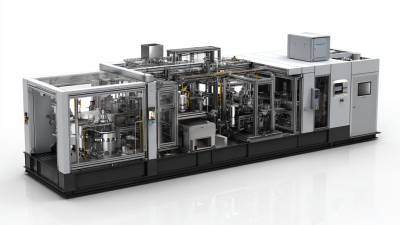

The pharmaceutical landscape is witnessing a transformative shift in oncology manufacturing, driven by advanced turnkey solutions that streamline production processes while ensuring compliance with rigorous global standards. At the forefront of this evolution is IVEN Pharmatech, a pioneering supplier known for providing comprehensive engineering solutions for pharmaceutical factories around the world. With a focus on injectable oncology applications, their OEB5 injectable oncology vial turnkey plant exemplifies this innovation, offering state-of-the-art design and high-quality equipment tailored to meet the specific needs of the industry.

The OEB5 solution not only enhances the efficiency of oncology drug production but also adheres to stringent regulatory requirements outlined by authorities like the EU GMP and US FDA. IVEN Pharmatech’s commitment to delivering customized services spans a wide range of products including Non-PVC soft bag IV solutions, PP bottle IV solutions, glass vial IV solutions, and injectable vials and ampoules. This integrated approach allows pharmaceutical manufacturers to seamlessly navigate the complexities of production while maintaining the highest quality standards, ultimately contributing to improved patient outcomes in oncology care.

By providing a comprehensive range of products and services from project design to final implementation, IVEN Pharmatech is not just facilitating the manufacturing of essential drugs, but also driving innovation in the oncology sector, ensuring that healthcare providers have access to the life-saving treatments their patients need.

FAQS

: They are essential for ensuring product integrity and safety by preventing contamination and ensuring efficacy of pharmaceuticals and biologics.

The global market for vial sealing machines is projected to reach USD 1.5 billion by 2027, growing at a CAGR of 6.4%.

Many modern machines are equipped with sensors and feedback systems that monitor sealing pressure and temperature, providing real-time data to operators.

Smart sealing solutions with IoT capabilities improve operational efficiency and reduce downtime by enabling predictive maintenance.

They need to handle various vial sizes and materials, which is crucial due to the growing demand for personalized medicine and dynamic manufacturing requirements.

They should evaluate sealing speed, compatibility with different vial sizes, and the machine's adaptability to future production needs for better productivity and profitability.

Regulations promoting recycling and reduced plastic waste, along with a strong focus on eco-friendly materials and technologies, are driving this demand.

The increase in these sectors contributes to heightened consumption of advanced sealing solutions, with the pharmaceutical packaging market estimated to reach $160 billion in 2023.

They enhance product integrity and consumer trust by focusing on safety and efficacy in drug delivery systems.

They can significantly reduce labor costs, minimize product waste, and achieve long-term efficiency gains, which leads to better operational effectiveness.

Related Posts

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

-

The Future of Efficient Cartridge Filling Machine Innovations

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

Blog Tags: