Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

Table of Contents

- The Rise of Blow Fill Seal Technology in Global Trade

- Understanding Blow Fill Seal Ampoules: Key Features and Benefits

- China's Role in Innovating Blow Fill Seal Manufacturing

- Comparative Analysis: Blow Fill Seal vs. Traditional Packaging Methods

- Success Stories: Global Brands Leveraging Chinese Blow Fill Seal Solutions

- Future Trends in Blow Fill Seal Technology and Global Market Impact

- Innovative BFS Solutions: Revolutionizing IV and Ampoule Product Packaging for Improved Safety and Efficiency

- FAQS

- Related Posts

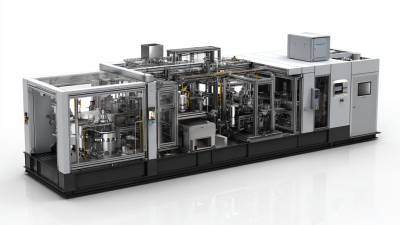

In today's world, where global trade gets more competitive every day, having innovative and high-quality products really makes all the difference. Shanghai IVEN Pharmatech Engineering Co., Ltd. is right there on the frontlines of this shift, with its four specialized factories focused on pharmaceutical machinery, blood collection tube equipment, and water treatment systems. One of their standout innovations is the development of Blow Fill Seal Ampoules, which are truly changing the game when it comes to packaging and delivering medicines. These advanced ampoules not only keep sensitive liquids safer and more intact but also make the manufacturing process smoother and more efficient. It’s clear they’re playing a big role in boosting global trade. And as China continues to lead the way in manufacturing excellence, these innovative solutions are making waves far beyond borders, setting higher standards for quality and efficiency in the pharmaceutical industry around the world.

The Rise of Blow Fill Seal Technology in Global Trade

Hey, have you noticed how Blow Fill Seal (BFS) technology is really shaking things up in the global pharma scene? It’s pretty exciting stuff! As the demand for smarter, safer packaging for medicines, vaccines, and liquids keeps growing, BFS has become a total game-changer. I recently came across some market reports saying that this tech is expected to grow at an annual rate of over 9% between 2022 and 2027. A big part of that is because the industry is really pushing for safer, more efficient solutions — and BFS checks all those boxes.

Here’s the cool thing: companies like Shanghai IVEN Pharmatech Engineering are leading the charge. They’ve got four dedicated factories focusing on top-notch machinery for BFS, blood collection tubes, and even water treatment stuff. They’re all about supporting the global market and helping manufacturers step up their game. Switching to BFS isn’t just about reducing contamination risks — it actually helps cut down production costs too, making it a pretty popular pick worldwide.

If you’re thinking about jumping into BFS, worth chatting about a few things first: like, how big is your operation, and what exactly do you need it for? It’s important to make sure it suits your scale and complies with all those tricky global regulations. Partnering with experienced suppliers can make the whole transition way smoother — trust me, it’s worth it to get it right from the start.

Understanding Blow Fill Seal Ampoules: Key Features and Benefits

Blow fill seal (BFS) ampoules really mark a major jump forward in how the pharmaceutical industry packages things. Basically, they let you do a bunch of steps — like blowing a plastic preform, filling it up with the medication, and sealing it all in one go. And the best part? It’s done in a super sterile environment, so there's less chance of contamination. That means not only is production faster and more efficient, but the product stays safer and more reliable. With more automation and less human handling involved, BFS technology helps streamline the whole process while still sticking to all the strict rules and standards required.

Now, as for the perks of BFS ampoules—they’re pretty impressive. They do an excellent job protecting sensitive medicines from things like moisture or light, thanks to their top-notch barrier qualities. Plus, their tight sealing keeps even tricky or volatile ingredients safe from leaks. On top of that, they’re more eco-friendly since they usually use fewer materials than older packaging methods, which means less waste. With international trade booming, it’s clear these ampoules are set to be a key player in safely and efficiently getting pharmaceuticals to people around the world—really showing off China's innovative manufacturing side.

China's Role in Innovating Blow Fill Seal Manufacturing

You know, China has really stepped up as a major player when it comes to innovation in Blow Fill Seal (BFS) manufacturing. They've totally changed the game for how pharmaceuticals and other sterile products are packaged. Thanks to cutting-edge tech and huge manufacturing capabilities, Chinese companies are now setting pretty high standards for quality and efficiency. The BFS process itself isn’t just about safety—by cutting down contamination risks—it also makes production smoother and helps bring products to market faster and cheaper.

As the world’s craving more biologics and aseptic solutions, China’s heavy investment in R&D has put their BFS tech right at the top of the industry. They're all about adopting the latest machinery and robotics, making sure everything’s precise and up to international standards. Plus, with a growing number of skilled folks and a real innovation-driven environment, China’s reshaping the whole landscape of sterile manufacturing on the global stage. All this doesn’t just keep China at the forefront of BFS; it also creates exciting opportunities for international partners who want to tap into these advancements and grow together.

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way - China's Role in Innovating Blow Fill Seal Manufacturing

| Dimension | Value |

|---|---|

| Global Market Share (%) | 25% |

| Annual Production Capacity (Million Units) | 1200 |

| Innovative Processes Implemented | 7 |

| Export Markets Covered | 50+ |

| Investment in R&D (Million USD) | 30 |

| Sustainability Initiatives | 5 |

| Employment Generated | 3000 |

Comparative Analysis: Blow Fill Seal vs. Traditional Packaging Methods

In today’s fast-changing world of global trade, China’s top-of-the-line blow fill seal (BFS) ampoules really stand out as a huge leap forward in packaging tech. When you compare it to older methods, BFS clearly offers a bunch of benefits—especially in pharma, where keeping things sterile and ensuring the product stays intact is super important. I came across a report from Research and Markets that predicts the BFS market will grow at an impressive rate of over 8% from 2021 to 2026, which shows people are really starting to embrace this cool new method.

Now, if you think about traditional packaging like vials and syringes, they usually need several handling steps. That’s not just a hassle—it also ups the chances of contamination and waste. BFS changes that game by combining filling and sealing into one smooth, continuous process. This means less chance for outside contaminants to get in. A study from the Journal of Pharmaceutical Sciences even shows that BFS ampoules have contamination rates below 0.1%, whereas traditional packs hover around 2-3%. That’s a pretty huge difference in safety! Not only does this improve the quality of the products, but it also helps put consumers at ease—making sure they trust what they’re getting. All in all, cleaner, safer packaging means better products and more confidence, which definitely helps with global trade moving forward.

Success Stories: Global Brands Leveraging Chinese Blow Fill Seal Solutions

Lately, there's been a real uptick in demand for packaging that’s not just efficient but also

super safe—especially in the pharma and beauty worlds.

I mean, if you look at the latest reports from MarketsandMarkets, they’re saying the global

blow-fill-seal (or BFS) market is set to skyrocket, hitting about

$9.9 billion by 2026. And it’s growing at roughly

8% every year. A big reason for all this?

China is really pushing the envelope with its innovation

and high-quality products. Companies over there are using advanced BFS tech to produce

all sorts of ampoules and containers, and it shows.

Big global brands are actually leaning more and more on Chinese manufacturers for their BFS needs.

Why? Because they’re known for delivering sterile, top-notch packaging that actually plays

by the rules and meets all the tough regulations. For example, some of the biggest pharma players

switched to BFS technology because it’s not just cheaper—it also means there's less chance of contamination.

The process doesn’t require much manual handling, which cuts down on human errors big time. There was

even a case study in the International Journal of Pharmaceutical Sciences where a healthcare

giant said they managed to cut their production costs by about

30% after switching to Chinese BFS solutions. That kind of

impact really shows how this smart packaging tech isn’t just talk; it’s changing the game.

Future Trends in Blow Fill Seal Technology and Global Market Impact

The progress of Blow Fill Seal (BFS) tech is really set to shake up global trade, especially in pharma and food stuff. You know, as top manufacturers in China lead the way, we’re probably gonna see some cool trends shaping what’s next for BFS. Companies are really leaning into automation and smarter ways of manufacturing—stuff that cuts down on waste and rocks out higher production at the same time. It’s not just about making things safer; it also helps keep costs down, which is great news for folks everywhere.

If you're looking to stay on top of the BFS game, investing in R&D is a no-brainer. Getting a good handle on what consumers want and what rules you need to follow is key if you wanna hit the sweet spot—being compliant and still making products people actually want.

And, honestly, sustainability is becoming more than just a buzzword; it’s a big deal now. As people become more eco-aware, BFS tech is adapting too—using recyclable materials and consuming less energy. By doing that, manufacturers can tap into a market that seriously cares about protecting the planet.

Oh, and here’s a tip: teaming up with suppliers who focus on eco-friendly packaging solutions could really boost your brand’s image and attract environmentally conscious buyers. It’s a win-win all around.

Innovative BFS Solutions: Revolutionizing IV and Ampoule Product Packaging for Improved Safety and Efficiency

In the ever-evolving landscape of medical technology, Innovative BFS Solutions are setting new benchmarks in the packaging of intravenous (IV) and ampoule products. This cutting-edge approach prioritizes safety and efficiency, meeting the critical demands of healthcare providers and patients alike. The BFS system employs a sophisticated algorithm designed to facilitate the precise and secure delivery of medications. By ensuring that each dose is packaged with unparalleled accuracy, this solution significantly reduces the risk of medication errors, enhancing patient safety.

Furthermore, the user-centric design of the BFS system stands out, as it simplifies the training process for healthcare workers. With its intuitive interface, medical staff can quickly become proficient in using the system, which streamlines operations in hospitals and clinics. This ease of use, combined with the affordability of the BFS solution, offers a compelling case for healthcare facilities looking to optimize their medication delivery processes. By embracing this innovative technology, institutions can not only enhance their operational efficiency but also deliver safer care to their patients.

FAQS

: BFS ampoules are a type of pharmaceutical packaging created by blowing a plastic preform, filling it with a product, and sealing it all within a sterile environment, enhancing production efficiency and minimizing contamination risks.

The key benefits include superior barrier properties against moisture and light, hermetic sealing to prevent leakage, reduced waste due to material efficiency, and enhanced product safety.

BFS ampoules minimize human handling and maintain a sterile environment during production, which reduces the risk of contamination and helps to keep the integrity of the pharmaceutical product intact.

China is a leader in BFS manufacturing, employing advanced technologies, extensive manufacturing capabilities, and a focus on quality and efficiency, thereby revolutionizing sterile product packaging.

The BFS process streamlines production, reducing costs and time-to-market by enhancing safety and minimizing contamination risks.

BFS technology typically uses fewer materials than conventional packaging methods, resulting in less waste and a smaller environmental footprint.

China's investment positions its BFS capabilities at the forefront of the industry, allowing for adoption of advanced machinery and robotics that meet international regulatory standards.

BFS ampoules can efficiently and safely deliver pharmaceuticals worldwide, reflecting the innovation and manufacturing prowess of China's pharmaceutical sector.

Related Posts

Blog Tags: