Understanding the Essentials of Automated Filter Tube Production Techniques

Table of Contents

- Key Differences in Automated vs Manual Filter Tube Production Methods

- Benefits of Automation in Filter Tube Manufacturing Processes

- Evaluation of Material Choices for Automated Filter Tube Production

- Cost Analysis: Automated Production versus Traditional Techniques

- Impact of Technology Advancements on Filter Tube Quality and Efficiency

- Future Trends in Automated Filter Tube Production Techniques

- FAQS

- Conclusion

- Related Posts

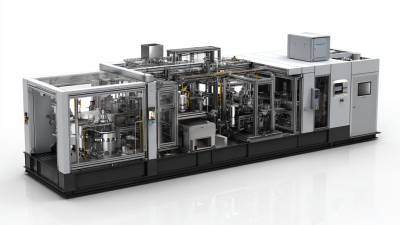

The world of pharmaceutical manufacturing is changing pretty quickly these days. One of the coolest upgrades we've seen is in Automated Filter Tube Production. I recently came across a report from MarketsandMarkets that estimates the global pharma packaging market could hit around $1.4 trillion by 2026. That growth is mainly fueled by the huge demand for more efficient and dependable production methods.

Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are really pushing the envelope here—they've got four specialized factories focusing on pharma machinery, blood collection tube equipment, and water treatment systems. But of course, the industry isn’t without its hiccups—challenges like contamination and inconsistent quality keep popping up. That’s where automated filter tube production techniques come in—they’re becoming a key part of the solution. In this blog, I’ll walk you through what these techniques are all about, the common issues manufacturers face, and how forward-thinking companies like Shanghai IVEN Pharmatech are leading the way toward safer, more efficient production standards.

Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are really pushing the envelope here—they've got four specialized factories focusing on pharma machinery, blood collection tube equipment, and water treatment systems. But of course, the industry isn’t without its hiccups—challenges like contamination and inconsistent quality keep popping up. That’s where automated filter tube production techniques come in—they’re becoming a key part of the solution. In this blog, I’ll walk you through what these techniques are all about, the common issues manufacturers face, and how forward-thinking companies like Shanghai IVEN Pharmatech are leading the way toward safer, more efficient production standards.

Key Differences in Automated vs Manual Filter Tube Production Methods

When it comes to making filter tubes, deciding between automated and manual methods can really influence things like efficiency, quality, and costs. Automated production uses high-tech machinery, which means you can crank out units pretty quickly with minimal hands-on work. This almost always results in more consistent quality and precision because machines can run nonstop without getting tired or making mistakes like humans sometimes do. Plus, automation makes it easier to scale up production—so if demand suddenly spikes, you're better equipped to keep up without sacrificing quality.

On the flip side, manual production has this personal, flexible feel to it. It’s great if you’re after a bit of craftsmanship or unique touches, but honestly, it tends to be less efficient and slower. You need skilled workers to do the job, which can limit how much you can produce at a time. And let’s be real: manual processes can lead to some variability in quality since humans can have off days or different styles. When there's a big order or high-volume demand, manual methods might struggle to keep up, causing longer wait times or even backorders. In the end, choosing between automated and manual really depends on what your company's needs are, what resources you have, and where you see your growth going. It's definitely worth taking a good look at the pros and cons of each before making a call.

Comparison of Production Efficiency: Automated vs Manual Filter Tube Production

Benefits of Automation in Filter Tube Manufacturing Processes

In today's fast-changing world of manufacturing, automation has really become a game-changer, especially when it comes to making filter tubes. It’s not just about saving on labor costs—though that’s definitely part of it. Automated systems boost precision and keep production consistent, which means fewer mistakes and smoother timelines. For companies like Shanghai IVEN Pharmatech, who are into making pharma equipment and blood collection tubes, switching to automated filter tube production really helps ensure top-notch quality and keeps everything in line with industry standards.

And here's the thing—automation can actually save a ton of money over the long run. With less money spent on wages and higher output, companies can free up resources to focus on R&D and be more innovative. Plus, with real-time data analytics at your fingertips, it’s easier to make smarter decisions and fine-tune the production process on the fly. As industries like pharma keep pushing for high-quality, reliable products, investing in automation isn’t just a passing trend—it’s pretty much essential for staying competitive and succeeding in the market today.

Understanding the Essentials of Automated Filter Tube Production Techniques

| Production Technique | Automation Level | Production Speed (Units/Hour) | Cost Reduction (%) | Quality Improvement (%) |

|---|---|---|---|---|

| Injection Molding | High | 200 | 30 | 40 |

| Blow Molding | Medium | 150 | 25 | 35 |

| Extrusion | High | 300 | 20 | 30 |

| Filtration | Low | 80 | 15 | 20 |

Evaluation of Material Choices for Automated Filter Tube Production

When it comes to choosing materials for automated filter tube manufacturing, it's a pretty crucial step. Picking the right stuff can really make a difference in how well the products perform—and also in how sustainable they are. Recently, there's been some pretty exciting progress showing that composite materials often beat traditional metals in a lot of ways. For example, a review on using composites in automotive parts mentioned how they can help cut down weight, boost durability, and resist corrosion better—making them a top pick for automated production lines. Plus, using these advanced composites can actually help save money and energy in the long run. Industry reports are talking about how switching to these materials could slash lifecycle costs by around 25%. Pretty impressive, right?

And on top of that, as everyone’s getting more eco-conscious, there’s a clear move towards using greener stuff like water-based coatings and powder coatings. It’s all about meeting stricter rules on emissions and waste. The good news? Switching to these alternatives not only helps cut back on harmful solvent fumes but also aligns with global efforts to be more sustainable. By weaving these eco-friendly materials into the automated filter tube production process, manufacturers aren’t just making better products—they're also doing their part to protect the environment. It's kinda exciting to see how innovation and sustainability are coming together in such practical ways.

Cost Analysis: Automated Production versus Traditional Techniques

Over the years, the way automated filter tube production has evolved has really changed the game in manufacturing—especially when you look at the cost differences compared to the old-school methods. Lately, companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. have been leading the charge with new innovations in pharmaceutical equipment, especially for blood collection tubes. These new tech solutions don’t just boost efficiency; they actually cut down on labor costs quite a bit compared to traditional ways. Since these systems can handle repetitive tasks automatically, manufacturers can breathe a little easier and devote more time to quality control and coming up with fresh ideas, instead of just grinding away with manual labor.

If you dig into the cost details, it’s pretty clear that while setting up automated systems might be a bit pricey upfront, the savings down the line are pretty significant. Automation helps reduce human error, speeds things up, and keeps quality consistent—all of which are huge pluses for profits. On the flip side, sticking with traditional methods often means ongoing labor expenses and inefficiencies that can pile up over time. So, companies like Shanghai IVEN Pharmatech show us that jumping into automation isn’t just about keeping up with trends—it's really about setting yourself up for sustainable growth and staying competitive in today’s pharma world.

Impact of Technology Advancements on Filter Tube Quality and Efficiency

You know, it's pretty amazing how technology has really changed the game when it comes to making filter tubes. These days, the quality’s way better, and production is way more efficient. And if you look at the big picture, the global automotive filter market is expected to hit around $12 billion in 2023. Plus, it’s projected to grow at about 4.16% annually from 2024 to 2031. That just shows how important these new innovations are to keep up with the soaring demand for high-performance filters. The modern manufacturing process is pretty high-tech too — they’re using cutting-edge machines that ensure every filter is made with exact precision. That means filters can really stand up to the tough conditions in cars without breaking a sweat.

On top of that, with so many people paying more attention to air quality today, the filtration industry is booming in different areas. Take HEPA filters, for example — they’re expected to grow at a solid 8.1% rate until 2032, mainly because folks are more concerned about health and stricter air standards are in place. And then there’s the air purifier market, which is sitting at around $15.59 billion this year and is expected to grow about 7% annually from 2024 to 2031. All these numbers really show how there's a big demand for better, more reliable filtering solutions. Luckily, thanks to tech advances in how these products are made, we're seeing filters that perform better and last longer than ever before.

Future Trends in Automated Filter Tube Production Techniques

Looking ahead, the trends in automated filter tube production are really opening up some pretty exciting growth opportunities across various filtration markets. By 2033, it’s expected that the global backwash filter market will shoot up from around $311.5 million in 2025 to a whopping $2.157 billion—a solid growth rate of about 4.7% annually. A big part of this boom is thanks to tech advancements in filtration — making products more efficient and higher in quality, which everybody seems to want these days, no matter the industry.

If you're a manufacturer trying to get in on this action, it’s pretty clear you’ll need to invest in new and innovative production methods. Keep pushing automation forward — not only does it speed things up, but it also keeps your quality consistent, which is super important. Plus, adopting smart manufacturing tech can really give your operations a boost.

Pro tip: Focus on developing and incorporating cutting-edge filtration tech to stay ahead of the game. Make sure to keep an eye on market trends so you can tweak your product lineup as needed. And don’t forget—training your team on the latest automated processes will help you run things more smoothly and deliver top-notch quality, giving you a solid edge in the market and keeping your customers happy over the long haul.

FAQS

: The main benefits include enhanced precision and consistency, significant reductions in human error, optimized production timelines, and superior product quality.

Automation reduces labor costs and increases throughput, allowing businesses to redirect resources towards research and development.

Real-time data analytics enables better decision-making and allows for responsive adjustments to production lines to improve efficiency and quality.

The global backwash filter market is projected to grow from $311.5 million in 2025 to $2.157 billion by 2033, with a compound annual growth rate (CAGR) of 4.7%.

Investing in innovative production techniques allows manufacturers to capitalize on growth opportunities, enhance production speed, and ensure consistent quality.

Manufacturers can improve operational performance by implementing smart manufacturing technologies and regularly assessing market demands to adapt their product offerings.

Companies should focus on developing and integrating advanced filtration technologies, training staff in the latest automated techniques, and improving customer satisfaction to stay competitive.

Human error can lead to inconsistencies and defects; automation reduces this risk by enhancing precision and maintaining consistent production standards.

Automated manufacturing ensures superior product quality and compliance with stringent industry standards, which is crucial for pharmaceutical products.

Training staff in automated techniques streamlines operations, improves product quality, and enables better market positioning and customer satisfaction.

Conclusion

Automated filter tube production is truly a game-changer in manufacturing. Honestly, when you compare it with the old-school manual methods, the difference is pretty clear — things happen faster, more precisely, and on a bigger scale. This means companies can churn out high-quality filter tubes way quicker than before. We talk about automation a lot on our blog, and one of its biggest perks is that it cuts down on human errors and also helps save money on labor. That’s especially important for companies like Shanghai IVEN Pharmatech Engineering Co., Ltd., who are always looking for smarter ways to produce.

Plus, picking the right materials honestly makes a huge difference. It’s all about making sure the automated processes create products that aren’t just good-looking but also durable and dependable. Thanks to tech getting better all the time, both the quality and speed of filter tube production have skyrocketed. The industry’s looking pretty promising! If manufacturers do their homework—like analyzing costs carefully and keeping an eye on upcoming trends—they can really make the most of automated production. In the end, this means better performance and a stronger spot in the market for everyone involved.

Related Posts

-

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

-

The Future of Efficient Cartridge Filling Machine Innovations

-

Top Strategies for Ensuring the Validation of Capsule Filling Machines in Pharmaceutical Production

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

-

7 Compelling Reasons to Choose the Best Clean Steam Generator Manufacturers for Your Business Needs

Blog Tags: