The Future of Efficient Cartridge Filling Machine Innovations

Table of Contents

- Emerging Technologies in Cartridge Filling Machines

- Key Challenges in Traditional Cartridge Filling Methods

- Sustainability Trends in Cartridge Filling Innovations

- Automation and Its Impact on Cartridge Filling Efficiency

- Future Prospects: Smart Cartridge Filling Solutions

- User-Centric Design Approaches for Filling Machines

- Maximizing Efficiency in Cartridge Filling: Insights from the Latest Market Analysis and Industry Trends

- FAQS

- Related Posts

These days, with the global pharma industry expected to hit around USD 1.5 trillion by 2023, there's such a huge push for more efficient, high-quality manufacturing solutions. And among all these innovations, the Cartridge Filling Machine really stands out—it’s a key player in streamlining production and keeping product quality top-notch. Take Shanghai IVEN Pharmatech Engineering Co., Ltd., for example. They’re well-known for making some of the best pharmaceutical machinery out there, with four dedicated factories focused on innovation. Not only do they showcase the good stuff 'Made in China', but they’re also tough competitors when it comes to exports, offering cutting-edge solutions that really boost operational efficiency. As the market keeps changing and demands get tougher, improvements in Cartridge Filling Machines are going to be crucial for meeting tough regulations and crankin’ up production. It’s all about helping manufacturers stay ahead in serving the healthcare sector better, more efficiently, and more reliably.

Emerging Technologies in Cartridge Filling Machines

The world of cartridge filling machines is changing pretty fast these days, thanks to some cool new tech that's making everything more efficient and precise. Have you heard about how robotic automation is really shaking things up for pharma manufacturers? It’s true — innovations like planar motor technology and modular designs are now being used to build smarter filling systems that can handle all kinds of production needs. Not only do these advancements boost how quickly and accurately things get filled, but they also help keep everything sterile, which is super important in the pharma game.

Looking ahead, the market for aseptic filling machines is expected to grow a lot over the next decade. Experts are predicting it could hit close to USD 3.18 billion by 2034. That’s mainly because there's a big push for more reliable, efficient systems that can manage everything from vials to ready-to-use nested syringes. As manufacturers begin to explore all the possibilities with robotic systems, things like sustainable packaging and top-notch automation will definitely be key to shaping how cartridge filling technology evolves in the future.

Key Challenges in Traditional Cartridge Filling Methods

You know, traditional methods of filling cartridges have quite a few hurdles that really slow things down and cut into productivity in manufacturing. I came across a report from MarketsandMarkets — it says the global cartridge filling market could hit around $3.1 billion by 2025. That’s a big deal, but only if we can get past some pretty common obstacles. For instance, filling by hand is super labor-intensive, which often leads to inconsistencies, slower production rates, and even raises the chances of contamination. Surprisingly, data suggests that about 30% of the time spent in cartridge filling gets wasted because of these inefficiencies.

And then, there's the whole issue of quality control. This is especially critical in industries like pharma and cosmetics, where getting things just right is a must. A study published in the Journal of Manufacturing Science pointed out that nearly 1 in 5 batch failures—like 18%—are caused by incorrect filling techniques. That kind of thing really highlights why automation and smarter tech in filling machines are more important than ever. Using advanced automated systems doesn't just boost accuracy; it also cuts down on labor costs and helps make the final product better overall. As companies try to stay competitive and meet market demands, tackling these old-school problems with new tech isn’t just smart — it’s essential for growth that lasts.

Sustainability Trends in Cartridge Filling Innovations

As more and more industries are waking up to how important sustainability really is, we're seeing some pretty exciting innovations in cartridge filling machines. It's like everyone’s thinking, 'How can we do this greener?' Manufacturers are really rethinking their processes, focusing on cutting down energy use, reducing waste, and using recyclable materials whenever they can. These days, modern cartridge filling machines are packed with smarter tech that helps use less energy during operation and cut down on solvent emissions, which is a huge win for keeping things cleaner and greener.

Plus, there’s a real push towards using biodegradable and non-toxic materials for the cartridges, making the whole filling process more eco-friendly. Some of the coolest updates include smart automation and IoT features that give real-time data on resource use, helping companies fine-tune their operations and waste less. It's not just about being efficient — it’s also about matching those global sustainability goals, so businesses stay competitive in this eco-conscious market. By putting sustainability at the forefront of cartridge filling tech, companies can do their part for the planet while also appealing to customers who care about the environment. Honestly, it’s an exciting time to see how innovation is making a real difference.

The Future of Efficient Cartridge Filling Machine Innovations - Sustainability Trends in Cartridge Filling Innovations

| Innovation Aspect | Description | Sustainability Impact | Efficiency Improvement (%) | Estimated Cost Reduction (%) |

|---|---|---|---|---|

| Automated Filling Process | Utilizing robotics for precision filling | Reduces waste and enhances accuracy | 30% | 20% |

| Eco-Friendly Materials | Using biodegradable or recycled cartridges | Lowers environmental footprint | 15% | 25% |

| Smart Technology Integration | Incorporating IoT for real-time monitoring | Increases operational efficiency | 40% | 15% |

| Energy Efficient Machines | Reducing energy consumption in operation | Lower energy usage contributes to sustainability | 25% | 30% |

| Modular Machine Design | Flexible design allowing upgrades and repairs | Reduces waste through upgradability | 20% | 10% |

Automation and Its Impact on Cartridge Filling Efficiency

These days, with how quickly automation tech is changing, it's really shaking up how we do cartridge filling. Honestly, recent reports show that using automated systems can boost production rates by up to 50%. That’s a big deal because it cuts down a lot of the labor costs you’d otherwise spend on manual filling. For example, I came across a report from the International Society of Automation that says companies switching to fully automatic filling machines see cycle times drop dramatically — which means they get more product out the door and the quality actually gets better too.

Plus, automation's huge when it comes to cutting down human error, which is often a big headache in traditional filling setups. According to the National Institute of Standards and Technology, automated solutions can hit accuracy levels of around 99.9%, whereas manual methods tend to be about 95%. That kind of precision helps a lot with saving materials and making sure everything stays compliant with strict regulations — which is super important especially in industries like pharma or food and beverages. As the industry keeps pushing forward, integrating smarter tech like AI and IoT into filling machines is actually setting the stage for even more efficiency and a more sustainable future. It’s pretty exciting to see where all this is headed!

Future Prospects: Smart Cartridge Filling Solutions

As the demand for high-quality products keeps climbing, the way we fill cartridges is evolving pretty fast to keep up with industry needs. Lately, reports show that the global market for cartridge filling machines is expected to grow around 6.5% annually from 2023 to 2030. That growth is mainly fueled by more manufacturers adopting automation and smart tech in their production lines. These smarter filling machines, which are really leading the charge now, use AI and IoT features to make everything more precise and efficient.

What’s cool about these smart systems is that they not only speed up the whole process but also help cut down on waste and keep quality in check. For example, companies using these advanced filling solutions have seen filling mistakes drop by as much as 30%, really helping to keep the product quality consistent. Plus, with real-time data analytics, they can predict when maintenance will be needed — which means less downtime and better use of resources. Moving forward, the future of cartridge filling looks like it’s all about harnessing these innovative technologies to create production lines that are flexible, sustainable, and quickly adaptable to whatever market demands come next.

User-Centric Design Approaches for Filling Machines

You know, the way cartridge filling machines are designed is really shifting these days. More and more, manufacturers are focusing on making them user-friendly — it’s all about the user experience. The goal? Creating machines that not only get the job done efficiently but are also easy and even enjoyable for the end-user to operate. Honestly, in a competitive market, if your machines are simple to use and save time, you’re way ahead of the game.

So, how do you actually make this happen? Here are a few tips:

1. Talk to the users: Whether it’s through interviews, quick surveys, or watching how they use the machines, getting real feedback directly from people on the ground is gold. It helps you understand what really works and what doesn’t.

2. Test and refine: Don’t wait until the very end to check if things are working. Build prototypes early on, gather input, and then keep tweaking. This way, you catch issues early and end up with a better design overall.

3. Think about everyone: Make sure your design is accessible to everyone — from newcomers to seasoned pros, and people with different abilities. Things like clear labels, simple controls, and ergonomic setups really make a difference — they make the machine safer and easier to use.

By putting users front and center during design, the future of cartridge filling machines is looking pretty bright. Not only will they run more smoothly, but users will also be happier and more productive — a real win-win.

Maximizing Efficiency in Cartridge Filling: Insights from the Latest Market Analysis and Industry Trends

In the competitive landscape of cartridge filling, maximizing efficiency has become paramount for manufacturers aiming to enhance productivity and minimize waste. Recent market analyses indicate that the demand for automation in the filling process is steadily rising, with automated systems reportedly increasing production speeds by up to 30% while reducing the likelihood of human error. As manufacturers look to optimize their operations, the integration of advanced technologies into cartridge filling processes is key.

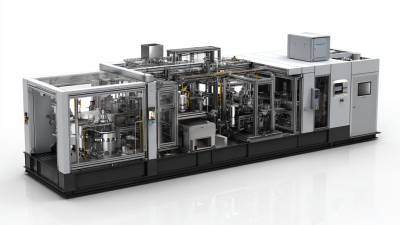

One standout solution that aligns with these industry trends is the IVEN cartridge filling production line. Designed specifically for the efficient production of cartridges and carpules, this system incorporates features such as bottom stoppering, liquid vacuuming to handle surplus liquid, and intelligent drying and sterilizing processes. Notably, the full safety detection and intelligent control mechanisms ensure that operations remain stable; functionalities like "no cartridge/carpule, no stoppering, no filling" significantly enhance reliability. A report valued the global cartridge filling equipment market at over $3 billion in 2022, underscoring the pivotal role that efficient filling systems play in meeting rising production demands.

Furthermore, the IVEN system's capability for automatic material feeding addresses a common bottleneck in cartridge production when supplies run low. This not only boosts operational efficiency but also contributes to an overall reduction in downtime. As manufacturers increasingly turn to high-tech solutions, the IVEN cartridge filling production line serves as a prime example of how innovative equipment can lead to heightened efficiency, aligning with current market trends and industry goals for maximum productivity.

FAQS

: Cartridge filling machines are equipment used for filling cartridges with pharmaceuticals or other liquids. They are evolving through advancements in robotic automation, planar motor technology, and modular designs to enhance efficiency and precision while maintaining aseptic conditions.

The market for aseptic filling machines is projected to grow significantly, potentially reaching nearly USD 3.18 billion by 2034, driven by the increasing demand for efficient systems capable of handling various applications, such as vials and nested syringes.

Automation enhances cartridge filling efficiency by increasing production rates by up to 50% and reducing labor costs. Automated systems minimize human error, achieving accuracy levels of 99.9%, which leads to improved throughput and product quality.

Automated filling machines provide higher accuracy (99.9% versus 95% for manual processes), reduce cycle times, decrease labor costs, and ensure compliance with regulatory requirements, ultimately enhancing reliability in industries like pharmaceuticals and food & beverage.

Future trends in cartridge filling technologies include the integration of smart features such as AI and IoT capabilities, leading to enhanced precision, operational efficiency, reduced filling errors, and improved quality control.

Smart cartridge filling solutions streamline production by minimizing waste, ensuring consistency, and utilizing real-time data analytics for predictive maintenance. This results in decreased downtime and optimized resource allocation.

The global market for cartridge filling machines is projected to grow at a CAGR of 6.5% from 2023 to 2030, driven by increased automation and the adoption of smart technologies.

Advanced technologies such as AI and IoT contribute to sustainability in cartridge filling by optimizing processes, reducing errors, and minimizing waste, ultimately creating agile production lines that can respond quickly to changing market demands.

Related Posts

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

Blog Tags: