The Future of Liquid Filling Machines: Innovations Shaping Tomorrow's Manufacturing

Table of Contents

- Understanding Liquid Filling Machines: Core Technologies and Their Evolution

- Key Innovations Revolutionizing the Liquid Filling Industry

- Sustainability in Liquid Filling: Eco-friendly Practices and Technologies

- Automation and Smart Technology: The Future of Liquid Filling Operations

- Choosing the Right Liquid Filling Machine: Essential Considerations for Manufacturers

- Emerging Trends: What to Expect in Liquid Filling Solutions Over the Next Decade

- Streamlining Production Efficiency with the Vial Liquid Filling Production Line

- FAQS

- Conclusion

- Related Posts

Hey, in the fast-changing world of manufacturing these days, Liquid Filling Machines are becoming more and more important across different industries — especially in pharma. I recently came across a report from MarketsandMarkets that says the market for these machines could hit around $5.6 billion by 2025, growing at about 4.5% annually. That’s a pretty solid rise, and honestly, it’s all because everyone’s looking for better precision and efficiency when packaging. It’s making innovations in liquid filling tech a big deal right now. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are really leading the charge, with four specialized factories focused on pharma machinery and more. As manufacturers of these machines, they’re not just keeping up with what the industry needs — they’re actually shaping the future with smarter solutions that boost both productivity and safety in manufacturing processes.

Understanding Liquid Filling Machines: Core Technologies and Their Evolution

Liquid filling machines have really become a big deal in today's manufacturing world. They’re constantly evolving, reflecting broader tech trends we see everywhere. If you look into their history, you’ll notice how automation, pinpoint accuracy, and new materials have played huge roles in shaping them. Recently, a report showed that the market for these machines is expected to grow by about 4.5% annually from 2022 to 2030—thanks mainly to the boom in packaged foods and drinks. As manufacturers get smarter with automation, these filling machines are becoming more advanced—fewer mistakes, more efficient runs, you know the drill.

And it’s not just about automation. Innovations like IoT—think real-time updates and smarter maintenance—are really changing the game. Now, operators can monitor everything on the fly, which means problems are caught early and supply chain stuff runs smoother. They’re also pouring money into data centers to keep everything cool and operating without a hiccup. Plus, breakthroughs in machine learning and robotics are making it easier to handle tricky filling jobs that used to be a headache. All these tech leaps are basically transforming liquid filling machines into something way more integrated with the industrial revolution happening now. Long story short, the future’s looking pretty exciting—these machines are set to shake up manufacturing across all sorts of sectors.

The Future of Liquid Filling Machines: Innovations Shaping Tomorrow's Manufacturing

This chart illustrates the evolution of core technologies in liquid filling machines over the past decade, highlighting key innovations that have driven efficiency and accuracy in manufacturing processes.

Key Innovations Revolutionizing the Liquid Filling Industry

The liquid filling machinery sector is really on the verge of some exciting changes that are going to shake up how things are done across different industries. Technology’s moving so fast right now, driving the market toward smarter, more efficient solutions—especially in the world of automated filling. While many manufacturers are jumping on the automatic bandwagon, there’s still quite a bit of demand for semi-automatic machines. These are perfect for specialized tasks or when clients have specific needs. What’s super cool is that now we’re seeing an uptake in smarter machines integrated with AI. This means more customized, precise filling—and let’s be honest, that’s a total game-changer as consumer tastes keep evolving.

The market for liquid filling machines is expected to grow from around $3.81 billion in 2018 all the way up to about $6.31 billion by 2032. That’s a pretty healthy compound annual growth rate (or CAGR) of around 3.4%. And it’s not just this segment—broader liquid packaging is booming too, predicted to hit over $373 billion by 2023 with a CAGR of roughly 5.2% through 2032. As filling tech advances—think vacuum, volumetric, and weigh-filling methods—companies are better equipped to meet the skyrocketing demand for packaged beverages. Plus, as new materials and techniques come into play, like cutting-edge glass substrates, we’re heading towards packaging that’s not only better for the products but also more sustainable overall.

Sustainability in Liquid Filling: Eco-friendly Practices and Technologies

These days, sustainability is pretty much a big deal in the manufacturing world, especially when it comes to liquid filling operations. You know, with everyone paying more attention to the environment, companies are really starting to adopt greener practices to cut down their ecological impact. Things like using biodegradable materials for packaging and installing systems that cut down on waste during filling—those are like, must-do steps if you wanna be more eco-friendly. Plus, with cool tech like AI-based analytics, companies can keep an eye on how much energy and resources they’re using. That way, they can make things more efficient, save some cash, and help the planet at the same time.

And it doesn’t stop there. Today’s filling machines are coming packed with features that boost sustainability. For example, some machines now have automatic cleaning systems that use way less water and chemicals. They keep everything clean without wasting tons of resources. And on top of that, lots of facilities are jumping on the renewable energy train—think solar panels or wind power—to make their operations even greener. By embracing all these innovations, manufacturers not only meet global sustainability goals but also catch the eye of eco-conscious consumers who really care about products made responsibly.

Automation and Smart Technology: The Future of Liquid Filling Operations

Wow, if you look at how quickly automation and smart tech are changing the game in liquid filling for manufacturing, it’s pretty incredible. Companies are really pushing to boost efficiency and get more precise results, and the buzz around advanced robots and AI solutions is growing fast. I read a recent report from MarketsandMarkets that says the liquid filling machine market might hit around $5.4 billion by 2026, with a compound annual growth rate of roughly 6.5%. That’s mainly because everyone wants to produce more, faster, and cut down on costs — so automated systems are definitely taking center stage over the old-school methods.

At Shanghai IVEN Pharmatech Engineering, we totally get how important this shift is. We’ve got four dedicated factories specializing in pharmaceutical machinery, blood collection tube equipment, and water treatment systems. Our goal is to stay ahead by integrating the latest tech into our products. Going digital and smart doesn’t just speed things up — it also boosts product quality with more accurate filling and less needed human handling. As the market demands more reliable and scalable manufacturing solutions, jumping on these tech advancements isn’t just smart — it’s essential for staying competitive in today’s fast-moving industry.

Choosing the Right Liquid Filling Machine: Essential Considerations for Manufacturers

So, whenever you're picking out a liquid filling machine, there are quite a few important things you should keep in mind to make sure everything runs smoothly and accurately. First off, you really need to consider whether the machine is compatible with the specific type of liquid you're working with—especially if you're in an industry dealing with sterile liquids. Did you know that the market for aseptic liquid filling machines is expected to hit around $6.8 billion by 2032? That’s pretty massive, so understanding what your product needs is super important. You want to make sure the machine can keep everything sterile during the filling process, because failing to do so could mean running into all sorts of regulatory headaches down the line.

On top of that, think ahead—scalability is a big deal. As your business grows, you'd want a machine that can handle different bottle sizes or get adjusted for liquids with different viscosities. Luckily, modern tech is making these machines more flexible than ever, so you can meet current market demands and also have room to expand later. With the industry expected to grow at about 4.79% annually from 2024 to 2032, investing in the right filling machine isn’t just a good idea—it’s a smart move to stay competitive and set yourself up for long-term success.

Emerging Trends: What to Expect in Liquid Filling Solutions Over the Next Decade

The liquid filling machine industry is really on the verge of some big changes. You can feel that emerging trends are about to reshape how manufacturing works over the next few years. Automation and smart tech are leading the charge here—more and more companies are bringing AI and IoT into their systems. It’s pretty exciting because it doesn’t just make everything more efficient; it also lets companies keep an eye on data in real time. That means they can fine-tune their production lines on the fly and cut down on waste, which is a huge win.

And then there's the whole focus on sustainability. You know, with environmental issues becoming a bigger deal, liquid filling solutions are stepping up their game. They’re using materials that are better for the planet, and there’s a lot of buzz around biodegradable containers and refillable packaging now. Consumers are more conscious of their ecological footprint these days, and manufacturers are responding to that. All in all, it’s pretty clear—this sector is moving towards smarter and greener ways of doing things. It’s kind of inspiring to see how production is shifting toward more responsible methods for the future.

Streamlining Production Efficiency with the Vial Liquid Filling Production Line

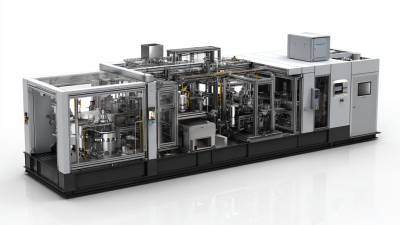

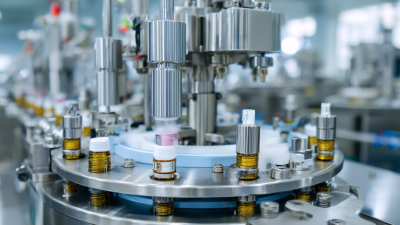

In the modern era of manufacturing, efficiency is paramount, especially in the production of pharmaceuticals and other liquid products. The Vial Liquid Filling Production Line exemplifies this drive toward streamlining operations. This sophisticated system seamlessly integrates several advanced machines, including a vertical ultrasonic washing machine, RSM sterilizing drying machine, filling and stoppering machine, and KFG/FG capping machine. Each component plays a critical role, ensuring that the entire process remains both efficient and sanitary.

The versatility of the Vial liquid filling production line is particularly noteworthy. Each machine can function independently or as part of a cohesive unit, adaptively meeting diverse production needs. The ultrasonic washing machine ensures thorough cleanliness, eliminating contaminants with precision. Following washing, the RSM sterilizing drying machine guarantees that vials are not only clean but also free from moisture—essential for effective filling and sterility. The filling and stoppering machine, paired with the capping machine, ensures accurate and reliable packaging, minimizing waste and enhancing productivity.

By investing in a fully integrated production line like this, manufacturers can significantly improve their production efficiency. The automated processes reduce human error, lower operational costs, and streamline workflows, ultimately leading to a higher output of quality products. In an industry where precision and cleanliness are crucial, the Vial Liquid Filling Production Line stands out as a dependable solution for modern manufacturing challenges.

FAQS

: The liquid filling machinery market is projected to grow at a CAGR of 4.5% from 2022 to 2030.

Key technologies include automation, precision filling, and advanced materials.

Smart manufacturing technologies, such as IoT integration, enable real-time monitoring, predictive maintenance, and enhanced supply chain management.

Manufacturers are adopting eco-friendly practices such as using biodegradable materials for packaging and reducing waste during the filling process.

AI-driven analytics help companies monitor resource usage, leading to optimized production rates and conservation of energy and materials.

Modern filling equipment includes automatic cleaning systems that reduce water and chemical usage, contributing to lower waste.

Renewable energy sources like solar or wind power are being incorporated into production facilities to support eco-friendly practices.

Sustainability helps manufacturers align with global goals and attract environmentally conscious consumers.

The evolution reflects broader industrial transformations through advancements in automation, machine learning, and robotics for better handling of complex tasks.

Thermal management is crucial for ensuring the efficient operation of technologies involved in the liquid filling process, particularly as data centers become more important.

Conclusion

Hey, have you checked out the blog titled "The Future of Liquid Filling Machines: Innovations Shaping Tomorrow's Manufacturing"? It dives into how quickly liquid filling tech is changing these days. The article kicks off by breaking down the main technologies that form the backbone of modern liquid fillers, giving a bit of a history lesson along the way. It’s pretty fascinating to see how far we’ve come! Then, it highlights all the cool innovations that are really transforming the industry right now. Plus, it spots the importance of eco-friendly practices—because, let’s face it, sustainability is more crucial than ever.

Looking ahead, the blog points out that automation and smart tech are becoming game-changers for making liquid filling processes faster and more efficient. It also gives some solid tips on how to pick the right machine, which is super helpful for manufacturers trying to keep up in such a competitive market. With all these exciting trends on the horizon, the insights shared here are definitely worth a read for anyone involved in this field. They’ll help get you ready for what’s coming in the next decade or so!

Related Posts

-

Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

Ultimate Guide to Efficient Glas Bottle Packaging Machines for Your Production Line

-

The Future of Efficient Cartridge Filling Machine Innovations

Blog Tags: