The Future of Pharmaceutical Safety: Revolutionary Aseptic Capping Machines Explained

Table of Contents

- Emerging Trends in Aseptic Capping Technologies for Drug Safety

- Key Features of Revolutionary Aseptic Capping Machines

- Enhancing Pharmaceutical Quality Control through Innovative Capping Solutions

- Automation and Efficiency: The Future of Aseptic Capping in Pharma

- Regulatory Compliance: Meeting Safety Standards with Advanced Capping Machines

- Innovative Solutions for Efficient Manufacturing: The Micro Blood Collection Tube Production Line

- FAQS

- Conclusion

- Related Posts

You know, in the fast-changing world of pharma manufacturing, keeping products safe and intact is more important than ever. That’s why the new Aseptic Capping Machines are such a big deal—they really mark a major step forward. I read somewhere that, according to Grand View Research, the global market for aseptic packaging could hit around USD 415.8 billion by 2027. That's mainly thanks to tighter safety rules and the growing need for contamination-proof processes.

Companies like Shanghai IVEN Pharmatech are really leading the charge here, with their four specialized factories focusing on all things pharmaceutical machinery and tech. By adopting these state-of-the-art Aseptic Capping Machines, manufacturers can not only speed things up but also stay within those tough safety standards. Ultimately, it all helps protect patients and makes sure the medicines they take are safe and effective.

Companies like Shanghai IVEN Pharmatech are really leading the charge here, with their four specialized factories focusing on all things pharmaceutical machinery and tech. By adopting these state-of-the-art Aseptic Capping Machines, manufacturers can not only speed things up but also stay within those tough safety standards. Ultimately, it all helps protect patients and makes sure the medicines they take are safe and effective.

Emerging Trends in Aseptic Capping Technologies for Drug Safety

You know, the pharmaceutical world is going through quite a shake-up lately, especially with these new aseptic capping technologies coming into play. It’s a huge deal because how we cap and package drugs directly impacts their safety and how well they work. I read somewhere (Grand View Research, I think) that the global market for aseptic packaging is expected to hit around $475.7 billion by 2027. That’s a clear sign that everyone’s really focused on keeping things sterile right from the start to the finish. This is especially true for biologics and injectable medicines—any contamination here could be disastrous, so it’s super important.

One of the coolest trends I’ve come across is the rise of these autonomous capping machines that are powered by robotics and AI. They’re designed to be super precise and cut down on human error. Plus, they help keep the environment sterile at all times. Interestingly, stats show that using automated capping can cut down contamination by up to 50% compared to the old manual methods. That’s a game-changer for companies trying to meet those tough regulatory standards.

A quick tip if you’re looking into these capping systems: it’s really worth paying attention to models that offer real-time monitoring. These systems can spot issues like pressure or temperature changes during the capping process right away, so you can fix things before any problems occur. Also, making sure your staff get proper training on these new machines is key—staying up-to-date with aseptic techniques helps keep everyone safe and the process smooth.

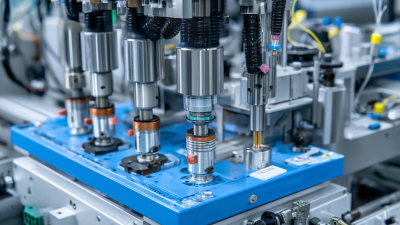

Key Features of Revolutionary Aseptic Capping Machines

Aseptic capping machines are really becoming crucial in making sure pharmaceutical products stay safe and untainted. These machines are designed to keep contamination at bay and to give vials and containers a secure, germ-free seal. I came across a recent industry report that predicts the aseptic packaging market will hit around $10.3 billion by 2026, growing at about 7.3% annually since 2021. That kind of growth just shows how important advanced tech is for keeping medicines safe.

Some of the coolest features these new aseptic capping machines have include really fast speeds, automation, and special sealing tech that ensures everything stays sterile. With all the latest tech packed in, these machines can work smoothly in sterile environments—which really cuts down on the risk of microbes sneaking in during filling.

Shanghai IVEN Pharmatech Engineering Co., Ltd. is doing some great work here, with their four specialized factories, pushing the boundaries of pharmaceutical machinery. They focus on creating innovative equipment that helps companies meet super strict safety standards while also keeping production efficient.

As the pharma world keeps evolving, investing in top-notch aseptic capping machines is pretty much essential for keeping products safe, compliant, and trustworthy.

Enhancing Pharmaceutical Quality Control through Innovative Capping Solutions

You know, the pharmaceutical world is always under pressure to step up its game when it comes to quality control — making sure medicines are both safe and effective. Lately, really cool innovations like these super advanced aseptic capping machines are pushing the boundaries even further. They’re built to fit right into the production line, creating a super sterile environment that helps cut down on contamination risks. And with things like automated monitoring and super precise capping, manufacturers can really boost the integrity of their products.

What's even better is that these aseptic capping machines aren't just all about quality — they're also a game changer for efficiency and growth. They can run at high speeds while keeping everything sterile, which means more products in less time, with fewer chances for mistakes. That’s great for safety and for keeping costs down, too. As the industry keeps changing and moving forward, these kinds of solutions will be pretty vital in making sure everything meets top-notch standards — ultimately helping to keep the public safe and healthy.

The Impact of Aseptic Capping Machines on Pharmaceutical Safety

Automation and Efficiency: The Future of Aseptic Capping in Pharma

The pharmaceutical industry is changing faster than ever before. Automation and efficiency are now the main players in modern manufacturing, really shaping how things are done. Aseptic capping machines, for example, are super important in this shift—they’re helping boost productivity while also keeping safety top-notch during the production of sterile meds. Interestingly, a recent report from Grand View Research predicts that the global aseptic packaging market will hit around $330 billion by 2027. That just shows how much demand there is for smarter, more advanced solutions in pharmaceutical capping.

With automation taking off, these aseptic capping machines have really cut down on contamination risks during filling and sealing. They’re packed with cool tech—like robots and real-time monitoring—that keep everything sterile. According to a study by the International Society for Pharmaceutical Engineering (ISPE), facilities that use automated capping have seen up to a 50% drop in downtime. That means they can produce more, faster, without sacrificing safety or quality. As pharma companies keep pushing for excellence in what they do, these machines are pretty much leading the charge—helping them stay compliant with regulations while also getting products out efficiently.

The Future of Pharmaceutical Safety: Revolutionary Aseptic Capping Machines Explained

| Feature | Description | Advantages | Impact on Efficiency |

|---|---|---|---|

| Automated Filling | High-precision automated systems for liquid filling | Minimizes human error and contamination risk | Increases throughput and reduces operation time |

| Robust Microbial Barrier | Advanced capping technology that provides a sterile seal | Ensures product integrity and safety | extends shelf life and reduces rework costs |

| User-Friendly Interfaces | Intuitive controls and display systems | Simplifies operation and reduces training time | Enhances overall production flow |

| Smart Monitoring Systems | Real-time data collection on performance | Facilitates predictive maintenance | Minimizes downtime and maximizes output |

| Scalability | Flexible designs that can adapt to different production volumes | Supports varying market demands | Enhances responsiveness to order changes |

Regulatory Compliance: Meeting Safety Standards with Advanced Capping Machines

In the pharma world, sticking to regulatory rules is kind of a big deal—especially when it comes to making sure medicines are safe for folks to use. That’s where those fancy aseptic capping machines come into play. They’re super important for hitting those strict safety standards set by agencies like the FDA and EMA. Did you know? A report from MarketsandMarkets predicts that the global aseptic packaging market will hit around $64.5 billion by 2025. That just shows how much more everyone’s stressing safety in drug manufacturing these days. These machines are pretty high-tech—they work hard to cut down on contamination risks, making sure each vial or bottle gets sealed in a sterile, mess-free environment.

Using these advanced capping machines not only helps companies stay on the right side of safety rules but also makes things run smoother and faster. According to a study by the International Society for Pharmaceutical Engineering (ISPE), switching to automated capping systems can cut down human error by half—meaning fewer product recalls and more trust from the people who end up using the meds. Plus, with the demand for production to be quicker than ever, these machines can speed up the capping process without sacrificing hygiene standards. And honestly, in today’s super competitive pharmaceutical scene, that’s a total game-changer.

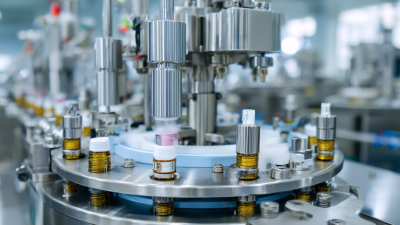

Innovative Solutions for Efficient Manufacturing: The Micro Blood Collection Tube Production Line

The advancements in medical technology have led to innovative solutions that enhance the efficiency of manufacturing processes, particularly in the production of micro blood collection tubes. These tubes are crucial for collecting blood samples from neonates and pediatric patients through easily accessible sites such as the fingertip, earlobe, or heel. The demand for these tubes has surged, with the global blood collection market predicted to reach approximately $18 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 5.6% from 2020.

The IVEN micro blood collection tube production line exemplifies the integration of automation in medical manufacturing. This one-piece production line significantly streamlines operations by automating the processes of tube loading, dosing, capping, and packing. This level of automation not only enhances productivity but also reduces the likelihood of human error, which is critical in a healthcare setting. Reports suggest that automated systems can improve workflow efficiency by up to 50%, enabling facilities to respond swiftly to increasing demands for diagnostic testing without compromising quality.

By employing such innovative machinery, manufacturers can operate with fewer personnel while maintaining a high standard of output. The IVEN system demonstrates a commitment to addressing industry needs, ensuring that the production of micro blood collection tubes meets the rising global demand while optimizing resources and labor. As the healthcare sector continues to evolve, solutions like the IVEN production line will play a vital role in delivering efficient, reliable products that support patient care and diagnostics.

FAQS

: Aseptic capping technologies are innovations that maintain sterile conditions during the packaging of pharmaceuticals, crucial for ensuring drug safety and efficacy, especially for biologics and injectables.

Autonomous aseptic capping machines utilize advanced robotics and AI to enhance precision and minimize human intervention, reducing contamination rates by up to 50% compared to traditional methods.

Key features include real-time monitoring systems for detecting pressure or temperature deviations, ongoing staff training in aseptic techniques, and the machine's ability to operate efficiently in sterile environments.

The global aseptic packaging market is projected to reach $475.7 billion by 2027, with the aseptic packaging segment alone expected to grow to $10.3 billion by 2026.

Innovative capping solutions integrate seamlessly into production lines, provide sterile environments, and utilize automated monitoring systems, leading to minimized contamination risks and higher product integrity.

Automation in aseptic capping processes allows for high-speed operation while maintaining sterility, reducing human intervention and potential errors, which improves overall safety in pharmaceutical packaging.

By investing in advanced aseptic capping equipment and regular training for personnel, manufacturers can ensure compliance with stringent regulatory standards and enhance product safety.

High-speed operation in aseptic capping machines allows for efficient production processes while maintaining stringent sterility requirements, enhancing overall output.

Shanghai IVEN Pharmatech Engineering Co., Ltd. is highlighted as a pivotal company developing innovative pharmaceutical machinery for aseptic capping processes.

Ongoing training ensures that personnel are well-versed in the latest aseptic techniques, which is essential for maintaining high safety standards in drug packaging operations.

Conclusion

Have you ever wondered about the future of pharmaceutical safety? The article titled "The Future of Pharmaceutical Safety: Revolutionary Aseptic Capping Machines Explained" really dives into how these new aseptic capping machines are playing a pivotal role in making medicines safer. It highlights some pretty exciting trends in the tech behind these machines—things designed to keep our drugs contamination-free. One of the coolest features? These machines are increasingly automated, which means they not only make the manufacturing process more efficient but also more reliable. It's like having a super-smart assistant working behind the scenes.

Plus, the piece stresses just how important these innovative capping solutions are when it comes to maintaining high quality control standards in pharma. With regulations getting stricter all the time, having the latest aseptic capping tech is pretty much essential if companies want to stay on top of safety requirements. And speaking of leaders in this field, Shanghai IVEN Pharmatech Engineering Co., Ltd. is definitely leading the charge. They've got the expertise and the know-how to produce cutting-edge machinery that meets the highest safety and quality standards in the industry.

Related Posts

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

-

How to Choose the Right Syringe Filter Manufacturers for Your Laboratory Needs

-

How to Maximize Production Efficiency with an IV Cannula Making Machine: A Data-Driven Approach

-

What is Efficient Blister Production and How It Transforms Pharmaceutical Packaging

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

The Future of Liquid Filling Machines: Innovations Shaping Tomorrow's Manufacturing

Blog Tags: