2025 How to Choose the Best Pharmaceutical Liquid Filling Machine for Your Needs

Table of Contents

- Understanding Pharmaceutical Liquid Filling Machines: An Overview

- Key Factors to Consider When Choosing a Liquid Filling Machine

- Types of Pharmaceutical Liquid Filling Machines Available in 2025

- Evaluating the Production Capacity and Speed Requirements

- Assessing Compatibility with Different Liquid Formulations

- Importance of Regulatory Compliance in Equipment Selection

- Budgeting for Purchase and Maintenance Costs of Filling Machines

- FAQS

- Conclusion

- Related Posts

As the pharmaceutical industry keeps evolving, there’s never been a more important time to have reliable and efficient packaging solutions. According to a report by Grand View Research, the global market for liquid filling machines in pharma is expected to hit around USD 3.5 billion by 2025, growing at a compound annual rate of roughly 5.9%. This boom is mainly fueled by the rising number of chronic conditions and the increasing demand for more sophisticated injectable medicines. So, choosing the right pharmaceutical liquid filling machine is pretty crucial for companies that want to ramp up their production without risking compliance with all those strict regulations.

Dr. John Smith, who’s been in the game for over 20 years, really stresses how important it is to pick the right equipment: “Getting a top-notch pharmaceutical liquid filling machine can make a world of difference in both efficiency and quality, and ultimately, it benefits the patients too.” As manufacturers try to streamline their filling processes, factors like automation, accuracy, and the ability to scale up are now front and center when making decisions. This article is here to shed some light on key things to think about — helping you find the best pharmaceutical liquid filling machine that suits your specific needs and production targets.

Understanding Pharmaceutical Liquid Filling Machines: An Overview

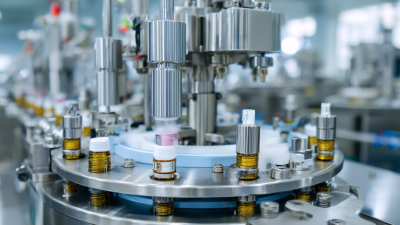

Pharmaceutical liquid filling machines are essential components in the production process within the pharmaceutical industry. These machines are designed to fill a variety of liquid products into containers such as vials, bottles, and syringes, ensuring precise dosage and maintaining the integrity of the liquid. Understanding the various types and features of these machines is crucial for selecting the right one to meet your company's specific needs.

When evaluating pharmaceutical liquid filling machines, consider factors such as the type of liquid being filled, the required filling speed, and the level of automation desired. Fully automated machines can significantly reduce labor costs and improve efficiency, while semi-automated options may be more suitable for smaller operations or specific filling requirements. Additionally, look for machines that comply with industry regulations and standards, as this is vital for maintaining product safety and quality.

**Tips:** Always assess the scalability of the liquid filling machine to ensure it can adapt to future production demands. Furthermore, prioritize machines with easy maintenance and cleaning protocols to minimize downtime and maintain compliance. Finally, consider the machine's compatibility with various container sizes, as this flexibility can enhance operational efficiency.

Pharmaceutical Liquid Filling Machines: Capacity Comparison

Key Factors to Consider When Choosing a Liquid Filling Machine

When selecting a pharmaceutical liquid filling machine, several key factors come into play to ensure that the equipment matches your specific operational needs. The first consideration should be the type of liquid being filled, as viscosity and density can influence the filling technology required. For instance, thicker formulations may need machines with specialized pumps to manage flow effectively, while high-speed operations may necessitate gravimetric or volumetric filling systems for precision.

Another important factor is the machine’s capacity and speed. Assessing the expected production volume will help determine whether a semi-automatic or fully automatic machine is best suited for your facility. Additionally, it’s crucial to consider the flexibility of the machine in accommodating different container sizes and types, as this versatility can significantly enhance operational efficiency and reduce downtime.

Tips: Always ask about the ease of cleaning and maintenance. Pharmaceutical production demands stringent hygiene standards, so machines that can be easily disassembled will save time during maintenance. Furthermore, review the available technological features such as touch-screen interfaces and automation capabilities, as these can greatly influence user experience and overall productivity. Finally, ensure that the machine complies with regulatory requirements pertinent to your market, which can help avoid costly compliance issues down the line.

Types of Pharmaceutical Liquid Filling Machines Available in 2025

In 2025, the pharmaceutical industry continues to evolve, showcasing a variety of liquid filling machines tailored to meet diverse production needs. Understanding the types of pharmaceutical liquid filling machines available is crucial for manufacturers seeking to enhance efficiency, accuracy, and compliance in their operations. Some of the prominent categories include volumetric filling machines, which utilize precise measurements to dispense a specific volume of liquid; and gravity filling machines, which rely on gravity to transfer liquids into containers, making them ideal for products with low viscosity.

Additionally, the market boasts aseptic filling machines specifically designed to maintain sterility throughout the filling process. These machines are essential for pharmaceuticals that require stringent hygiene standards. Another emerging type is the pump filling machine, which utilizes various types of pumps to handle different viscosities and ensure accurate filling. As technology advances, newer models also incorporate automation and integration features, allowing for uninterrupted production lines and higher output rates, which are vital for meeting the growing demand in the pharmaceutical sector. Choosing the right machine involves careful consideration of the product characteristics, production volume, and operational goals.

Evaluating the Production Capacity and Speed Requirements

When selecting a pharmaceutical liquid filling machine, evaluating production capacity and speed requirements is crucial. The pharmaceutical industry has stringent demands, with High-Performance Liquid Chromatography (HPLC) standards and aseptic processing requirements often dictating the need for precision and efficiency. According to the International Society for Pharmaceutical Engineering, production speeds can range from 30 to 300 bottles per minute, depending on the machine type and the viscosity of the liquid. Understanding your specific production volume, whether it’s large-scale or small-batch production, will help you choose a machine that aligns with your operational goals.

When assessing machine speed, consider factors such as the required turnaround time and the complexity of your filling process. A report from the Pharmaceutical Manufacturing Association notes that improving speed by just 10% can significantly enhance overall productivity, making the choice of machinery pivotal. Additionally, if your production demands include diverse bottle sizes or types, opt for machines designed for quick changeovers to minimize downtime.

Tip: Always conduct a thorough analysis of your current production workflow before making a decision. This can include measuring the volume of production runs and identifying bottlenecks in your existing processes. Another tip is to collaborate with engineers to customize your liquid filling machine based on precise speed and production capacity requirements to maximize efficiency and compliance with industry standards.

Assessing Compatibility with Different Liquid Formulations

When selecting a pharmaceutical liquid filling machine, assessing compatibility with various liquid formulations is crucial. Different formulations, such as emulsions, suspensions, and solutions, may have distinct properties that affect their flow and filling characteristics. For instance, highly viscous liquids may require specialized pumps and mechanisms to ensure accurate filling without causing damage or delays. Conversely, lighter formulations could benefit from machines designed for faster throughput.

Furthermore, consideration of additional factors like temperature sensitivity and the presence of particulates can influence the machine's design and operation. A filling machine that can seamlessly handle a range of liquid characteristics not only enhances productivity but also ensures that the integrity and quality of the pharmaceutical products are maintained throughout the filling process. Therefore, a thorough evaluation of liquid characteristics is essential for selecting the most suitable liquid filling machine to meet unique production needs.

2025 How to Choose the Best Pharmaceutical Liquid Filling Machine for Your Needs - Assessing Compatibility with Different Liquid Formulations

| Machine Type | Liquid Compatibility | Filling Speed (Bottles per Minute) | Accuracy (%) | Price Range ($) |

|---|---|---|---|---|

| Piston Filler | Viscous Liquids, Creams | 30 | ±1% | 5,000 - 15,000 |

| Vacuum Filler | Low Viscosity Liquids, Water-like | 40 | ±0.5% | 4,000 - 12,000 |

| Peristaltic Pump Filler | Biologics, Sterile Solutions | 50 | ±0.2% | 6,000 - 18,000 |

| Aseptic Filling Machine | Injections, Vaccines | 25 | ±0.1% | 20,000 - 50,000 |

| Rotary Filler | Liquids, Syrups | 100 | ±1.5% | 15,000 - 30,000 |

Importance of Regulatory Compliance in Equipment Selection

When selecting a pharmaceutical liquid filling machine, one of the foremost considerations should be regulatory compliance. Regulatory agencies, such as the FDA or EMA, impose stringent requirements on equipment used in the production of pharmaceutical products to ensure safety, efficacy, and quality. A machine that meets these standards not only reduces the risk of legal repercussions but also builds trust with customers and stakeholders. Focusing on compliance during selection helps prevent costly recalls and ensures that the manufacturing process adheres to Good Manufacturing Practices (GMP).

Additionally, understanding the specific regulations that pertain to your product is crucial. Different types of pharmaceutical liquids, be they injectables, intravenous solutions, or oral medications, may fall under diverse regulatory scrutiny. As such, evaluating the filling machine's design—its materials, cleanability, and validation capabilities—is essential. Machines that allow for seamless cleaning and maintenance can facilitate compliance with the required sanitation standards, which is vital in a sector where contamination must be meticulously controlled. By prioritizing regulatory compliance in your equipment selection, you not only abide by the law but also enhance operational efficiency and product safety.

Budgeting for Purchase and Maintenance Costs of Filling Machines

When selecting a pharmaceutical liquid filling machine, budgeting for both the initial purchase and ongoing maintenance costs is crucial. According to market research, the global liquid filling machine market is projected to exceed $4 billion by 2025, highlighting the growing investment in this technology. The initial cost of a filling machine can range significantly, typically from $10,000 to over $100,000, depending on the complexity and automation level of the equipment. It's essential to take into account not only the purchase price but also the anticipated maintenance costs, which can average around 5-15% of the machine's purchase price annually.

Tip: Always factor in the cost of spare parts and required components, as these can accumulate over time. The reliability of a filling machine can significantly impact your operations, thus choosing models known for their durability can help mitigate unexpected expenses.

Moreover, regular maintenance plays a crucial role in extending the lifespan of your equipment. Routine checks and servicing can prevent costly breakdowns and ensure the machine operates at optimal efficiency. Based on industry insights, facilities that establish a comprehensive maintenance schedule often report up to 30% reduction in operational downtime, leading to improved productivity and cost-effectiveness.

Tip: Consider investing in a preventative maintenance plan, as it not only prolongs equipment life but can also enhance performance, ultimately translating to better product quality and reduced waste.

FAQS

: You should consider the specific production volume required, whether it’s large-scale or small-batch production, as well as the expected speed of operation, which can range from 30 to 300 bottles per minute based on machine type and liquid viscosity.

Improving machine speed by even 10% can significantly enhance overall productivity, making the selection of machinery crucial for meeting operational goals.

Key factors include required turnaround time, the complexity of the filling process, and the need for quick changeovers for different bottle sizes to minimize downtime.

Analyzing the current production workflow helps identify production volume, bottlenecks, and areas for improvement, ensuring that the chosen machine meets the specific needs of the operation.

Different liquid formulations, such as emulsions and suspensions, have unique properties that can impact flow and filling characteristics, necessitating specialized machines for accurate filling.

Considerations include the viscosity of the liquid, temperature sensitivity, and the presence of particulates, all of which influence the appropriate design and operation of the filling machine.

Collaborating with engineers allows for customization of the liquid filling machine based on precise speed and production capacity requirements, enhancing efficiency and compliance with industry standards.

Specialized pumps and mechanisms are required for highly viscous liquids to ensure accurate filling without causing damage or delays during the process.

A filling machine that can handle diverse liquid properties enhances productivity and maintains the integrity and quality of pharmaceutical products throughout the filling process.

Conclusion

When selecting the best Pharmaceutical Liquid Filling Machine for your needs in 2025, it's essential to first understand the different types available and their specific functions. Key factors to consider include the production capacity and speed requirements, ensuring the machine aligns with your operational workflow. Assessing compatibility with various liquid formulations is crucial, as not all machines handle every type of substance effectively.

Additionally, regulatory compliance plays a vital role in equipment selection, as adherence to safety and quality standards is paramount in the pharmaceutical industry. Finally, budgeting for both the initial purchase and ongoing maintenance costs will help in making a financially sound decision while ensuring long-term operational efficiency. By taking these considerations into account, you can choose a Pharmaceutical Liquid Filling Machine that meets your unique production needs.

Related Posts

-

How to Optimize Your Production Line with a Vial Ampoule Machine

-

2025 Top 5 Pharmaceutical Liquid Filling Machines You Can't Miss

-

Understanding the Role of Bioreactor Manufacturers in Sustainable Bioprocessing Innovations

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

How to Select the Perfect Pharma Blister Cartoner Machine for Your Production Needs

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

Blog Tags: