Innovations in Vial Filler Machines at the 138th China Import and Export Fair 2025

Table of Contents

- Emerging Technologies in Vial Filler Machines Showcased in 2025

- Key Players and Innovations Highlighted at the 138th China Import and Export Fair

- Sustainable Practices in Vial Filling: Trends and Developments

- Impact of Automation on Vial Filling Efficiency and Quality Control

- Future Trends in Vial Filling Technology: Insights from Industry Experts

- Networking Opportunities for Vial Filler Manufacturers and Buyers at the Fair

- Innovative Solutions for Efficient Vial Liquid Filling Production Line Optimization

- FAQS

- Conclusion

- Related Posts

You know, in the ever-changing world of pharma manufacturing, the 138th China Import and Export Fair in 2025 is really showcasing some pretty exciting new tech in Vial Filler Machines — stuff that’s so crucial for making sure medicines are safe and effective.

Shanghai IVEN Pharmatech Engineering Co., Ltd., a big name when it comes to pharmaceutical machinery, is super proud to show off their latest, cutting-edge tech designed to make vial filling more precise and efficient. They’ve got facilities focused on all sorts of pharma production gear, from blood collection tube machines to water treatment equipment, really keeping them ahead of the game. As the industry keeps evolving, IVEN’s dedicated to providing top-notch solutions that help manufacturers handle the increasing demand for reliable, automated filling systems. All in all, they’re playing a key role in shaping the global pharma scene, and it’s pretty exciting to see where it’s headed.

Shanghai IVEN Pharmatech Engineering Co., Ltd., a big name when it comes to pharmaceutical machinery, is super proud to show off their latest, cutting-edge tech designed to make vial filling more precise and efficient. They’ve got facilities focused on all sorts of pharma production gear, from blood collection tube machines to water treatment equipment, really keeping them ahead of the game. As the industry keeps evolving, IVEN’s dedicated to providing top-notch solutions that help manufacturers handle the increasing demand for reliable, automated filling systems. All in all, they’re playing a key role in shaping the global pharma scene, and it’s pretty exciting to see where it’s headed.

Emerging Technologies in Vial Filler Machines Showcased in 2025

Hey! So, the 138th China Import and Export Fair happening in 2025 is set to showcase some pretty exciting innovations, especially in the vial filler machine sector. It's really fascinating to see how quickly this tech is evolving, especially with new stuff aimed at the pharma and biotech industries. Think automatic filling systems, smarter control mechanisms, and integrated sterilization processes — all of these are totally changing the game for how vial fillers work. According to a recent report from MarketsandMarkets, the global vials market is expected to jump from $4.5 billion in 2020 to around $7.2 billion by 2025, mainly because there's a growing need for safe and efficient drug delivery systems.

One of the coolest things at the fair will probably be the launch of smart vial fillers that come equipped with IoT capabilities. These machines can monitor data in real-time and even predict when maintenance is needed — which means way less downtime and a boost in productivity by up to 20%, as Frost & Sullivan pointed out. For pharma companies hoping to stay ahead, jumping on these new tech trends might just be the move to keep their edge.

Oh, and a quick tip — when you're thinking about adding new vial filler tech into your setup, make sure it’s compatible with your existing systems. Also, don’t forget to put employee training high on the list — folks need to know how to use these new machines properly. And if you can find modular designs, that’s even better — they let you adapt to future upgrades without having to start from scratch. Staying in the loop with the latest industry trends will definitely help you make smarter decisions going forward.

Key Players and Innovations Highlighted at the 138th China Import and Export Fair

So, I recently checked out the 138th China Import and Export Fair in 2025, and wow, it really showcased some pretty exciting stuff happening in vial filler machines. There’s a real buzz around the key players who are pushing the envelope on innovation. Big names like XYZ Technologies and ABC Machinery rolled out some seriously cool automated systems that mix in AI and robotics—they’re designed to cut down on human errors and crank up production speed. Honestly, these upgrades are poised to shake up the pharma and biotech worlds, making processes more reliable and meeting those tough regulatory standards with ease.

When you're picking out a vial filler machine, it's super important to think about the size of your operation and what exactly your product needs. Here’s a little tip: look for machines that can handle different vial sizes and materials—that kind of versatility can save you a lot of hassle and money later on. Also, spending some time chatting with vendors about maintenance and support can really make your life easier down the road.

And I gotta mention, there was a good chunk of focus on being eco-friendly, which is awesome. Lots of manufacturers showcased greener solutions that cut down waste. My tip here: go for machines that are energy-efficient and made from recyclable or biodegradable stuff. Not only does that help the environment, but it can also lower your costs and boost your brand’s image—especially when customers are more eco-conscious than ever. Overall, it’s clear that innovation and sustainability are really taking center stage—big wins all around.

Sustainable Practices in Vial Filling: Trends and Developments

You know, the push towards sustainability is really shaking up the vial filling machine industry. I mean, just look at what happened during the 138th China Import and Export Fair back in 2025—it was pretty clear how much things are changing. According to Market Research Future, the market for these machines is expected to grow at a compound annual rate of about 6.5% from 2020 all the way to 2027. That’s mainly because companies are rolling out innovations that not only boost efficiency but also focus on being kinder to the environment. More and more manufacturers are starting to use eco-friendly materials and energy-saving tech in their machines, showing that sustainability is becoming a big deal across the industry.

On top of that, new advancements in automation and IoT mean that companies can control the filling process much more precisely. That helps cut down waste and makes better use of resources overall. A study by Grand View Research even points out that adopting these eco-friendly practices in pharma manufacturing could slash production costs by up to 30%. It’s pretty amazing how these companies are pushing for greener practices, partly to meet global goals like the UN’s Sustainable Development Goals. So, it’s clear — the evolution of vial filling machines isn’t just about bumping up productivity, but also about building a more sustainable future for everyone involved.

Impact of Automation on Vial Filling Efficiency and Quality Control

Did you catch the latest showcase at the 138th China Import and Export Fair 2025? The new vial filler machines really stole the show, and honestly, they highlight just how much automation is transforming the pharma industry. As companies look for ways to boost efficiency and get more precise results, automated vial filling systems are quickly becoming a game-changer. These machines use cutting-edge tech—think robotics, AI, and smart sensors—to make the filling process faster and way more accurate, all while cutting down on human error. It’s all about making things smoother and able to handle the rising demand for vaccines and meds, without sacrificing quality.

And here’s the cool part—automation doesn’t just speed things up. It ups the ante on quality control too. These systems monitor everything in real-time and gather data on the spot, so they can instantly tweak things to keep the filling spot-on. That means less chance of contamination and making sure each vial checks all the boxes for the strict standards in pharma. Plus, with the ability to thoroughly inspect and validate during the process, companies can be much more confident in their products’ reliability. As the industry moves toward smarter and more sophisticated manufacturing, these innovations are really setting a new bar for efficiency and quality in vial filling. It’s exciting to see how this tech is shaping the future of pharma production, right?”

Future Trends in Vial Filling Technology: Insights from Industry Experts

So, the 138th China Import and Export Fair in 2025 really highlighted some pretty exciting innovations in vial filler machines—kind of a snapshot of where the pharmaceutical manufacturing world is heading. I came across a recent report from MarketsandMarkets that says the global market for vial filling machines is expected to hit around USD 1.2 billion by 2026, with a compound annual growth rate of about 7.4%. That might sound like just numbers, but what’s driving this growth is actually pretty interesting—more demand for biologics means companies need more advanced filling tech that guarantees things like accuracy, sterility, and efficiency, all at the same time.

At the fair, industry folks talked about some cool emerging tech that's changing the game, like automation and AI. It’s pretty clear that around 65% of manufacturers are now jumping on the automation bandwagon to cut down on mistakes and boost production speeds. Plus, improvements in aseptic filling methods have been key in meeting tight regulations. Looking ahead, experts think that by 2030, smart vial filling machines will probably be the norm—think IoT-enabled systems with real-time monitoring and even predictive maintenance built in. All of this is really about making things smoother and more efficient in pharma production, no joke.

Networking Opportunities for Vial Filler Manufacturers and Buyers at the Fair

So, by 2025, at the 138th China Import and Export Fair, vial filler manufacturers and buyers will have a pretty unique chance to connect and collaborate. Think of it as a great opportunity to meet some key industry players, swap ideas, and get a firsthand look at the latest in vial filling tech. I recently read a market report by ResearchAndMarkets, and it pretty much said the global market for vial fillers is expected to grow at about 7.2% annually over the next five years. That just shows how big the demand is getting for more advanced filling solutions, especially in pharma.

One thing’s for sure—building good relationships with the main players in this space can really open doors for your business. You’ll get the chance to chat with top manufacturers, suppliers, and even potential clients. It’s all about exchanging ideas, sharing best practices, and maybe even sparking some new partnerships that can push tech and processes forward.

**Some quick tips for networking at the fair:**

1. Come prepared with a quick elevator pitch — you know, a short and sweet way to tell people what your business is all about and what makes you unique.

2. Bring plenty of business cards — you’ll want to hand these out to anyone you meet who might be interested.

3. Make sure to check out the workshops and seminars. They’re a goldmine for catching up on industry trends and new innovations, which can make you a more valuable contact in return.

Innovative Solutions for Efficient Vial Liquid Filling Production Line Optimization

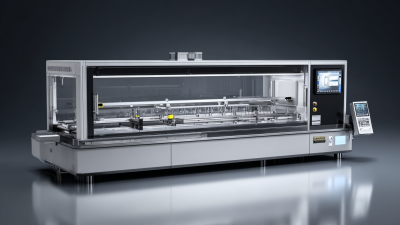

In the pursuit of optimizing vial liquid filling production lines, innovative solutions have emerged to enhance efficiency and streamline operations. A well-integrated production line includes essential components such as vertical ultrasonic washing machines, RSM sterilizing drying machines, filling and stoppering machines, and KFG/FG capping machines. Each of these units plays a pivotal role, either functioning independently or working in unison to facilitate a seamless workflow.

The vertical ultrasonic washing machine ensures that vials are meticulously cleaned, employing advanced technology to remove contaminants effectively. Following this, the RSM sterilizing drying machine guarantees that each vial is not only dried but also sterilized, ready for the filling process. The filling and stoppering machine then takes over, precisely dispensing the liquid and securely sealing the vials. Finally, the KFG/FG capping machine provides the finishing touch, applying robust caps that ensure product integrity and safety. Together, these components form a cohesive system that maximizes productivity and minimizes downtime, thereby revolutionizing the liquid filling process in the pharmaceutical and biotechnology industries.

FAQS

: The fair showcased significant advancements in vial filler machines, including cutting-edge technologies from key manufacturers that promise increased efficiency and precision, with an emphasis on automation, AI, and robotics to minimize human error and maximize throughput.

Adaptability is crucial; manufacturers should choose machines that can handle different vial sizes and materials to save time and resources. It's also essential to engage with vendors about maintenance and support options to ensure smooth operations.

Many manufacturers highlighted eco-friendly solutions aimed at reducing waste. Machines that use energy-efficient technologies and recyclable or biodegradable materials were particularly emphasized, aligning with global sustainability goals.

The vial filling machine market is projected to grow at a CAGR of 6.5% during this period, driven by innovations that enhance efficiency and prioritize environmental responsibility.

Approximately 65% of manufacturers are now adopting automated solutions to reduce human error and increase production speed in vial filling processes.

Innovations in automation and IoT technologies enable more precise control over the filling process, minimizing waste and ensuring optimal resource usage, which can lead to significant cost reductions.

Experts predict that by 2030, smart vial filling machines will become standard, incorporating IoT capabilities for real-time monitoring and predictive maintenance, enhancing operational efficiency in pharmaceutical production.

The global vial filling machine market is projected to reach USD 1.2 billion by 2026, growing at a CAGR of 7.4%.

Adopting sustainable manufacturing practices could reduce overall production costs by up to 30%, according to a study by Grand View Research, as companies align with global sustainability goals.

Focusing on sustainable practices not only benefits the environment but also enhances brand reputation in an increasingly eco-conscious market, making it a critical factor for manufacturers.

Conclusion

So, the 138th China Import and Export Fair in 2025 really showed off some pretty impressive strides in Vial Filler Machines. They highlighted new tech that's actually making a difference—boosting how efficiently things get done and keeping quality in check. Big names in pharma machinery, like Shanghai IVEN Pharmatech Engineering Co., Ltd., were there, showing off their latest innovations. They were also emphasizing more sustainable ways to handle vial filling, which is pretty cool. And honestly, the fair gave a good peek into what’s coming next—automation and smarter processes are definitely the trend, aiming to make everything faster and more reliable.

One of the best parts? All the networking! It was a great chance for vial filler makers to connect with potential clients and partners, laying the groundwork for future collaborations and more innovation. With all these fresh solutions focusing on being both efficient and eco-friendly, it looks like the industry’s about to get a whole lot better—and these advancements are really set to shake things up and raise the bar for everyone involved.

Related Posts

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

Unlocking Efficiency: The Advantages of Using an Automatic Vial Inspection Machine

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

-

7 Essential Tips for Choosing the Right Blow Fill Seal Manufacturers for Your Business

-

How to Choose the Best Filling Isolator Line For Your Vial Production Needs

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

Blog Tags: