Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

Table of Contents

- Benefits of Automatic Vial Inspection Machines in Pharmaceutical Manufacturing

- Key Technologies Driving Quality Control in Vial Inspection

- Industry Statistics: The Impact of Inspection Machines on Defect Reduction Rates

- Case Studies: Successful Implementations of Vial Inspection Solutions

- Future Trends in Automatic Inspection Technology for Quality Assurance

- FAQS

- Conclusion

- Related Posts

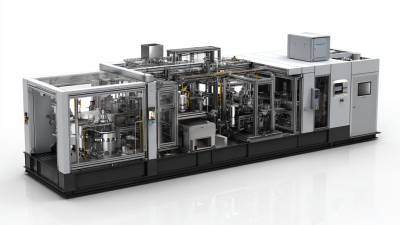

You know, the pharmaceutical world is really zeroing in on quality control these days — making sure medicines are both safe and effective. One of the coolest tools popping up is the Automatic Vial Inspection Machine. It’s becoming pretty much a must-have for manufacturers who want to step up their quality game. I read somewhere that, according to Grand View Research, the global market for these automated quality control tools could hit around $8.2 billion by 2027. That just shows how much everyone’s leaning on technology these days to cut down human error and make things run smoother. And speaking of innovation, Shanghai IVEN Pharmatech Engineering Co., Ltd. is definitely leading the charge with their four specialized factories, which focus on pharmaceutical machines, blood collection tube machinery, and water treatment gear. By bringing these advanced inspection machines into their production lines, companies are slashing defects and making sure they’re sticking to the tightest industry standards. All of this really boosts product reliability and, honestly, helps consumers trust the medicines they’re taking a lot more.

Benefits of Automatic Vial Inspection Machines in Pharmaceutical Manufacturing

Automatic vial inspection machines are really changing the game in pharmaceutical manufacturing. They’re helping companies step up their quality control game in a big way. With these smart systems, it's now possible to achieve 100% in-process control—yeah, every single vial gets checked! This is a huge deal given how much pressure there is to be both quick and safe in the industry. As production ramps up and regulations get even tougher, using automated tech isn’t just a nice-to-have anymore; it’s pretty much essential if you want to keep things running smoothly and minimize human mistakes.

Lately, there have been some pretty exciting innovations too. More and more, companies are blending AI and automated filling tech into their quality checks. For instance, new machines now combine visual inspections with fancy leak detection methods, making sure each vial and syringe is thoroughly checked during production. Switching from manual checks to automated ones has really cut down on contamination risks and helps ensure the final products meet those strict safety standards. As more firms jump on this bandwagon, we can expect even more reliable manufacturing processes—which ultimately means safer products for patients and a stronger trust in the industry.

Key Technologies Driving Quality Control in Vial Inspection

The pharmaceutical industry is always under pressure to make sure their products are safe and reliable, especially when it comes to vial inspection. And honestly, a lot of that comes down to the tech they’re using. Things like advanced imaging systems, artificial intelligence (AI), and machine learning algorithms are really leading the charge in quality control. I came across a recent report from MarketsandMarkets that says the worldwide market for automatic inspection machines is expected to hit around $1.2 billion by 2025 — that’s pretty impressive, especially with an annual growth rate of about 8.4%. It just shows how much demand there is for precision and making sure everything’s spot-on during the manufacturing process.

What’s fascinating is how integrating high-res cameras with smart software helps these machines spot tiny defects—things like cracks, particles, or even fill level issues. Research from Pharmaceutical Technology even suggests that these systems can detect defects up to 98% of the time, which is a huge boost in catching faulty products before they reach consumers. Plus, the AI-driven data analysis gives manufacturers real-time insights, so they can tweak their processes on the fly and keep things running smoothly. As more companies jump on board with these kinds of innovations, keeping strict quality control is only going to become more crucial — it's all about making sure the meds we rely on are safe and trustworthy.

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

Industry Statistics: The Impact of Inspection Machines on Defect Reduction Rates

The inspection machines market is really booming right now, especially in the semiconductor and electronics industries. As manufacturing gets more complicated, folks are pretty much relying on automated inspection tech like never before. It’s a big deal—by 2032, sales of semiconductor defect inspection equipment are expected to jump from around $6.14 billion in 2025 all the way to nearly $11 billion. Companies are starting to see just how crucial these machines are for cutting down defect rates. This shift is actually a huge step towards making products that are higher quality and more reliable, especially in high-tech fields.

Looking at the numbers, it’s clear these inspection machines are making a serious impact. The worldwide market for semiconductor wafer inspection tools could hit about $15.75 billion by 2034, growing at an annual rate of roughly 8.6%. That’s pretty impressive and shows just how much manufacturers need smarter solutions to cut errors and boost efficiency. Plus, the use of new tech like synthetic data in machine vision is really changing the game—making defect detection more accurate and adaptable in real time. These innovations aren’t just speeding things up; they’re also setting new standards for quality across the industry.

Case Studies: Successful Implementations of Vial Inspection Solutions

Lately, the pharmaceutical industry has been really leaning on automatic vial inspection machines to step up their quality control game. These high-tech solutions not only make inspections way easier and faster but also help cut down on human mistakes—so only the really good products make it to customers. There are some pretty inspiring stories out there of companies that have adopted these systems and seen big changes. For example, one pharma company managed to drastically cut down on defective vials, which meant they could stick to strict regulations and, on top of that, build more trust with their customers.

Then there’s this notable case of a well-known Chinese appliance maker. They managed to use some pretty innovative inspection tech to better protect their international trademarks. By taking a proactive, systematic approach, they could spot potential issues in their packaging much earlier in the process. That helped them reduce waste and boost efficiency—plus, it kept their brand reputation intact. All this aligns with their bigger goal of staying ahead in the competitive global market. These kinds of examples really show how automatic inspection tools are becoming a game-changer in manufacturing today, especially in industries where quality really matters.

Future Trends in Automatic Inspection Technology for Quality Assurance

As manufacturing keeps evolving, using automatic inspection tech is honestly becoming more and more crucial for making sure products meet quality standards. Looking ahead, the big buzz is around artificial intelligence and machine learning — stuff that really takes automatic vial inspection machines to the next level. These innovations don’t just make inspections faster and more accurate; they can also learn and adapt on the fly, reducing human error and making production smoother overall.

Lately, we’ve seen new frameworks like DATARUBRICS popping up, aiming to fix some of the issues we’ve had with traditional data assessment tools. Basically, they focus on setting clear, measurable quality benchmarks when it comes to machine learning datasets. When manufacturers start using these kinds of data-driven approaches, they can seriously improve their quality control, consistently hitting those high standards we all want.

As more companies jump on board with these advanced solutions, the whole landscape of quality assurance in manufacturing is about to change quite a bit — setting higher standards for efficiency and excellence that we haven’t seen before.

FAQS

: Automatic vial inspection machines are advanced systems used in pharmaceutical manufacturing to enhance quality control processes by ensuring 100 percent in-process control (IPC).

These machines significantly reduce the risk of contamination and ensure that products meet stringent safety standards by automating the inspection process.

Key technologies include advanced imaging systems, artificial intelligence (AI), and machine learning algorithms that enable accurate detection of defects.

The global market for automatic inspection machines is projected to reach $1.2 billion by 2025, growing at a CAGR of 8.4%.

AI-driven analytics enhance defect detection rates by up to 98%, allowing for proactive adjustments in manufacturing processes and improving overall operational efficiency.

The shift is important as it significantly reduces the risk of human error, which can compromise the quality and safety of pharmaceutical products.

These systems can detect defects such as cracks, particulates, and inconsistencies in fill levels in vials or syringes.

Real-time data allows manufacturers to make proactive adjustments to processes, enhancing operational efficiency and ensuring product quality.

Integrating technology into quality control mechanisms promotes thorough checks of products, improves reliability, and ultimately benefits patient safety and product integrity.

Manufacturers are increasingly adopting automated inspection solutions to meet tightening regulations and the growing demand for efficiency and safety in pharmaceutical production.

Conclusion

In the fast-changing world of pharma manufacturing, Automatic Vial Inspection Machines are really making a difference when it comes to quality control. These machines don’t just speed up the inspection process—they also help cut down on defects, making sure everything meets those tough industry standards. Thanks to cool tech like machine vision and AI, upgrades in this area are happening all the time, making inspections more precise and faster than ever.

If you look at the industry numbers, it’s clear these machines are a game-changer—less errors mean safer medicines for patients and lower production costs for companies. There are plenty of success stories out there too—companies that have adopted automatic vial inspectors and seen big improvements in their operations and quality assurance. Looking ahead, it seems like automation and tech innovation will only keep moving forward in this space, keeping companies like Shanghai IVEN Pharmatech at the forefront of these exciting developments.

Related Posts

-

The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Ultimate Guide to Efficient Glas Bottle Packaging Machines for Your Production Line

-

Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

Blog Tags: