Exploring Innovation: Liquid Filling Machine Manufacturers at the 138th Canton Fair 2025

Table of Contents

- Overview of the 138th Canton Fair: Focus on Innovation in Liquid Filling Machinery

- Key Liquid Filling Machine Manufacturers to Watch at the 138th Canton Fair

- Innovative Technologies Showcased by Liquid Filling Machine Manufacturers

- Sustainability Trends in Liquid Filling Machines at the 138th Canton Fair

- Networking Opportunities for Industry Professionals at the Canton Fair

- Future Prospects for Liquid Filling Machinery: Insights from the Canton Fair

- Optimizing Vial Liquid Filling Production Lines for Enhanced Efficiency and Quality in Pharmaceutical Manufacturing

- FAQS

- Conclusion

- Related Posts

As the 138th Canton Fair gets ready to kick off in 2025, everyone's buzzing about how the manufacturing scene is evolving — and a big highlight is the cool new stuff being showcased by Liquid Filling Machine Manufacturers. It’s pretty much the go-to event for industry leaders to show off their latest innovations and tech breakthroughs. One company that really catches the eye is Shanghai IVEN Pharmatech Engineering Co., Ltd. They’ve got a solid lineup of four specialized factories focusing on pharmaceutical machinery, blood collection tube equipment, and water treatment solutions. When you start digging into the opportunities coming out of the Canton Fair, it’s clear that liquid filling machines are playing a huge role in boosting production efficiency and keeping things precise across different sectors. This isn’t just about showing off new gadgets — it’s also about highlighting how dedicated these manufacturers are to quality and innovation, especially in today’s fast-changing marketplace.

Overview of the 138th Canton Fair: Focus on Innovation in Liquid Filling Machinery

Hey, have you heard about the 138th Canton Fair happening in 2025? It's shaping up to be a real hotspot for innovation, especially when it comes to liquid filling machinery. With everyone talking about the latest in manufacturing tech these days, this event is bound to showcase some pretty exciting stuff—things like new liquid filling machines that aim to boost both efficiency and accuracy in production lines. The exhibitors there will get a chance to show off their newest innovations, whether it's automation upgrades, greener production methods, or smart tech integrations—pretty much reflecting what the beverage and food industries are looking for these days.

If you swing by, you'll find a bunch of different machine setups, all designed for different uses—whether you're filling sodas, pharmaceuticals, or other liquids. It's a fantastic place for manufacturers to connect with potential clients, investors, and industry experts. Plus, it’s all about pushing the boundaries of what's possible in liquid packaging tech. Sustainability’s also a big focus—they’re actively reworking processes to cut waste and save energy, aligning with the global shift towards greener, more eco-friendly production practices. Basically, it’s an event you won’t want to miss if you’re into the latest and greatest in this field.

Key Liquid Filling Machine Manufacturers to Watch at the 138th Canton Fair

The 138th Canton Fair is just around the corner, and it's shaping up to be a fantastic event for anyone interested in the latest in liquid filling technology. You'll find some really innovative manufacturers there, shaking things up in the industry. One name that definitely stands out is Shanghai IVEN Pharmatech Engineering Co., Ltd. They've got four specialized factories focused on different areas: pharmaceutical machinery, blood collection tube equipment, and water treatment systems. People are really noticing their commitment to quality and their use of cutting-edge tech — especially since the industry is expected to grow at around 8.5% annually through 2027, according to recent market forecasts.

If you’re thinking of checking out the fair, keep an eye on the key players who’ve recently come out with advanced filling solutions that are not only super efficient but also precise. With automation becoming more and more common, many manufacturers are starting to sprinkle in AI and IoT tech into their machines. This definitely helps boost productivity and makes the whole process a lot more reliable.

A quick tip: When you're exploring different liquid filling machine makers at the fair, make sure to look into how innovative their tech is, how good their customer service is, and the variety of products they can offer. It’s also worth asking about their after-sales support and whether they incorporate sustainable practices into their manufacturing. All these little details can really make a difference in your buying decision — and, of course, in how satisfied you’ll be down the line.

Innovative Technologies Showcased by Liquid Filling Machine Manufacturers

So, at the 138th Canton Fair in 2025, innovation totally stole the show! All the liquid filling machine manufacturers were there, showing off some pretty cool, cutting-edge tech aimed at making production smoother and more precise. It’s pretty amazing how these new gadgets don’t just help streamline the whole process but also keep up with what different industries—especially pharma and food processing—really need. The latest models are packed with smart features, automation, and interfaces that are super easy to use. Bottom line? They’re all about boosting productivity without compromising on quality.

And then there’s Shanghai IVEN Pharmatech Engineering Co., Ltd.—a real player in this space. These guys have their hands in quite a few pies, with four specialized factories focusing on pharmaceutical machinery, blood collection tube equipment, and water treatment gear. Their facilities really show their dedication to innovation and top-notch quality. They’re constantly pushing the envelope, developing advanced liquid filling machines that meet all the strict standards industry demands. By using the latest engineering practices, IVEN not only improves manufacturing workflows but also keeps solidifyng its spot as a leader in the market. Honestly, they’re also helping push the tech forward at the fair, and it’s pretty exciting to see what’s coming next!

Sustainability Trends in Liquid Filling Machines at the 138th Canton Fair

So, at the 138th Canton Fair in 2025, it's pretty clear that sustainability is gonna be a big deal among liquid filling machine makers. Everyone's trying to meet eco-friendly standards these days, right? Because of that, the global market for these machines is expected to grow quite a bit — we're looking at around $3.2 billion by 2026, with a CAGR of about 5.5% (according to TechSci Research from 2022). Manufacturers aren’t just focusing on making their machines more efficient anymore; they’re also trying to cut down on environmental impact. That shift is largely driven by consumers increasingly wanting sustainable packaging and greener manufacturing practices.

One of the coolest trends right now is the push for energy-efficient tech in these machines. Studies show that with the help of smart sensors and automation, some machines can cut their energy use by up to 30% compared to older, traditional models (Smithers Pira, 2023). On top of that, many manufacturers are now using recycled materials for parts and designing machines with modular features — so it’s easier to upgrade or fix things without replacing the whole thing. As the industry heads toward greener ways of working, folks at the Canton Fair will definitely be on the lookout for innovative solutions that show off these sustainability efforts. It’s all about staying competitive in a market that’s increasingly conscious of its environmental footprint.

Networking Opportunities for Industry Professionals at the Canton Fair

The upcoming 138th Canton Fair in 2025 is shaping up to be an incredible opportunity for folks in the industry, especially those working with liquid filling machines. It's one of the biggest trade events out there, bringing together experts, manufacturers, and distributors from all over the world. Honestly, it’s a lively hub for meeting people, swapping ideas, and even discovering new tech. Attending this fair isn’t just about showing off what you’ve got; it’s also about making connections that could turn into real business partnerships and help your growth.

Plus, the fair is happening alongside other major shows, like the 9th Asia-Pacific Cleanroom Technology & Equipment Exhibition. That really adds to the buzz, giving attendees a chance to dive into even more industry conversations and meet a wider range of folks. If you're involved in this space, it’s a perfect opportunity to catch up on the latest trends, see some innovative products, and grow your network—all while enjoying the vibrant culture of Guangzhou. Honestly, it’s a key event that could really influence the future of liquid filling machines and beyond, so don’t miss out!

Exploring Innovation: Liquid Filling Machine Manufacturers at the 138th Canton Fair 2025

| Company Type | Location | Machine Capacity (L/min) | Technology Level | Main Application |

|---|---|---|---|---|

| Manufacturer | China | 30 | Automatic | Food & Beverage |

| Supplier | Germany | 50 | Semi-Automatic | Pharmaceutical |

| Distributor | USA | 20 | High-tech | Cosmetics |

| Manufacturer | Italy | 40 | Manual | Beverage |

| Supplier | Japan | 25 | Automatic | Household |

Future Prospects for Liquid Filling Machinery: Insights from the Canton Fair

Hey there! So, with the 138th Canton Fair coming up in 2025, it's pretty exciting to see how the liquid filling machinery world is about to get a big boost. Recent industry chatter suggests that the global market for liquid filling machines is on track to hit around USD 5.3 billion by 2026, growing at roughly 5.8% annually. A lot of this boom is coming from the rising need for smarter, more efficient packaging solutions—whether it's food, drinks, meds, or cosmetics.

From what folks are saying about the Canton Fair, we'll probably get a sneak peek at some really cool innovations—like smarter automation systems and tighter precision tech. I read somewhere that about 60% of manufacturers are now throwing IoT into the mix to ramp up efficiency and cut down on downtime. These tech upgrades aren't just about speed—they’re also helping reduce waste since machines are getting better at filling exactly the right amount every time. Attending events like this is super helpful for manufacturers, because it’s where they can show off the latest innovations and get a sense of where the market’s headed in the near future.

Innovation Trends in Liquid Filling Machinery

Optimizing Vial Liquid Filling Production Lines for Enhanced Efficiency and Quality in Pharmaceutical Manufacturing

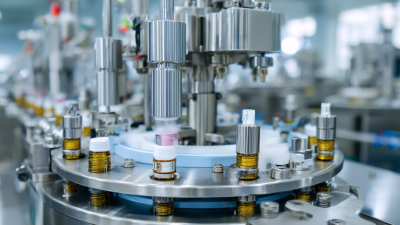

In the pharmaceutical manufacturing industry, optimizing vial liquid filling production lines is essential for enhancing both efficiency and quality. The integration of advanced machinery plays a crucial role in streamlining operations and ensuring that the manufacturing process meets stringent regulatory standards. The modern Vial liquid filling production line features several key components, including a vertical ultrasonic washing machine, an RSM sterilizing drying machine, and a filling and stoppering machine, all designed to function seamlessly together or independently as required.

The ultrasonic washing machine provides thorough cleaning of vials through high-frequency sound waves, ensuring the removal of any residual contaminants. Following this, the RSM sterilizing drying machine not only sterilizes but also dries the vials, preparing them for the filling process. Once cleaned and sterilized, vials proceed to the filling and stoppering machine, which precisely fills the vials with the desired liquid product and securely places stoppers. Finally, the KFG/FG capping machine applies the final touch by sealing the vials, thereby protecting the contents for storage and distribution.

This cohesive production line enhances overall efficiency by reducing bottlenecks and minimizing manual intervention, which can be prone to errors. Furthermore, the ability for each machine to operate independently provides flexibility, enabling manufacturers to adapt to varying production demands while maintaining high-quality standards throughout the process.

FAQS

: The 138th Canton Fair is a premier trading event that showcases innovative liquid filling machine manufacturers and facilitates networking among industry professionals.

Shanghai IVEN Pharmatech Engineering Co., Ltd. is a notable company at the fair, recognized for its specialized factories focusing on pharmaceutical machinery and advanced technology.

The industry is experiencing increased automation, with manufacturers incorporating AI and IoT technologies into their machines to enhance efficiency and reliability.

Attendees can build valuable connections, collaborate with global experts, and explore innovative technologies that can lead to partnerships and business growth.

The global liquid filling machines market is projected to reach USD 5.3 billion by 2026, growing at a CAGR of 5.8% due to rising demand in various sectors.

Attendees can expect insights into smart automation and enhanced precision systems that improve operational efficiency and sustainability in the filling processes.

After-sales support is crucial for ensuring long-term satisfaction and reliability in the performance of liquid filling machines, influencing purchasing decisions.

Sustainability is increasingly important as manufacturers strive to reduce material waste and optimize filling accuracy through advanced technologies.

The Canton Fair will coincide with the 9th Asia-Pacific Cleanroom Technology & Equipment Exhibition, enhancing opportunities for engagement across related industries.

Events like the Canton Fair are pivotal for showcasing cutting-edge technologies and understanding market trends that will shape the industry's future growth.

Conclusion

The 138th Canton Fair coming up in 2025 is shaping up to be a pretty big deal for anyone involved in liquid filling machinery. It’s a great chance to see the latest and greatest tech in action. Attendees can expect top manufacturers to showcase their newest innovations—solutions designed to boost efficiency and productivity, all while embracing the growing emphasis on sustainability we’re seeing these days.

There’s also plenty of opportunities to network — so if you're in the industry, it’s a perfect place to connect with others and chat about what’s next for liquid filling machines. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd., which runs four factories dedicated to pharma and machinery, will undoubtedly have a lot to contribute and share. As the fair goes on, all these insights and new ideas will help push the industry forward, solidifying its role as a key part of modern manufacturing processes.

Related Posts

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

Unlocking Efficiency: The Advantages of Using an Automatic Vial Inspection Machine

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

What is Efficient Blister Production and How It Transforms Pharmaceutical Packaging

-

Mastering the Art of Capsule Filling: A Comprehensive Guide for Global Buyers

Blog Tags: