How to Optimize Your Production Line with a Vial Ampoule Machine

Table of Contents

- Understanding Vial Ampoule Machines: Types and Applications in Production

- Key Benefits of Implementing Vial Ampoule Machines in Manufacturing Processes

- Optimizing Workflow Efficiency: The Role of Automation in Vial Filling and Sealing

- Industry Standards and Compliance: Ensuring Quality in Vial Ampoule Production

- Real-Time Performance Metrics: Tracking Production with Vial Ampoule Technology

- Future Trends: The Impact of Smart Technologies on Vial Ampoule Machine Optimization

- FAQS

- Conclusion

- Related Posts

In today's fast-changing pharmaceutical world, fine-tuning production processes isn’t just a good idea — it’s pretty much essential if you want to stay competitive and keep product quality top-notch. Plenty of manufacturers are turning to new tech, like the Vial Ampoule Machine, as a key part of their strategy. I recently read a market report by Grand View Research that estimates the global pharmaceutical packaging market could hit around USD 1 trillion by 2026. That growth is mainly driven by the rising need for safe and efficient ways to deliver medicines. Here in Shanghai, companies like IVEN Pharmatech Engineering Co., Ltd. — with their four specialized factories focused on pharma machinery — are really leading the way in this shift. By adopting the latest technology, such as the Vial Ampoule Machine, businesses can boost their production speed, meet stricter regulations, and ultimately help improve patient outcomes while making the industry a bit more sustainable. Pretty exciting stuff, right?

Understanding Vial Ampoule Machines: Types and Applications in Production

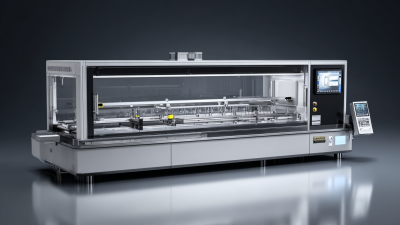

Vial ampoule machines play a pretty important role in today's production lines, especially in sectors like pharmaceuticals and cosmetics. There are different types out there, each tailored for specific jobs—whether you're running a small batch or a huge volume. For example, rotary vial filling machines are great for big batches because they can fill multiple vials at once, which really speeds things up. Meanwhile, linear ampoule filling machines are more precise and better suited for smaller quantities or specialized products. Picking the right machine? That's really about understanding what your production needs are—that’s key.

And it’s not just about filling either. These machines are pretty versatile—they can handle capping, labeling, and even inspection tasks. Many modern systems are super high-tech, often loaded with robotics and AI to keep things running smoothly, cut down on human errors, and boost overall quality. Using the right setup not only gets the job done faster but also helps meet strict safety and hygiene standards, which are absolutely critical when making injectables. Bottom line: choosing the right machine setup can seriously crank up your productivity and make your whole line more efficient.

Key Benefits of Implementing Vial Ampoule Machines in Manufacturing Processes

Using vial ampoule machines in manufacturing really brings a bunch of benefits, especially in the pharma world where everything needs to be precise and top-notch. These machines make the fill and finish steps for parenteral drugs way smoother by automating key tasks, which helps cut down on human errors and speeds things up overall. As pharma companies keep looking for ways to optimize their processes, bringing these vial ampoule machines into the mix means they can count on a more steady and reliable output—crucial for meeting those strict sterility standards.

And it doesn’t stop there. When you add in advanced tech like blow-fill-seal (BFS) systems, it gives manufacturers even more options for packaging design and better sterility during filling. BFS is pretty cool because it forms, fills, and seals the containers all in one closed system, which really cuts down the contamination risk. It’s a smart move for handling sensitive meds safely and also taps into the bigger trend of automation in manufacturing. So, by leveraging these technologies, companies can get more out of their production lines while keeping their product quality sky-high.

Optimizing Workflow Efficiency: The Role of Automation in Vial Filling and Sealing

Automation has really turned into a total game-changer for the pharmaceutical manufacturing world, especially when it comes to filling and sealing vials. I read somewhere—that the global pharma packaging market is expected to hit around $1.4 trillion by 2026. A big part of that push is driven by smarter automated solutions that help get things done faster and cut down on labor costs. Machines like vial ampoule fillers with lots of advanced tech are making everything run smoother—cutting down human errors and keeping products safe and compliant with all the regs.

If companies jump on board and start using automated vial filling and sealing machines, they can see production speeds jump by up to 50%, according to a 2022 report by Smithers Pira. That’s pretty huge—it means faster turnarounds, and workers can spend less time on repetitive tasks and more on quality checks or other important stuff. Plus, automation makes it easier to track data and monitor processes in real-time, which kind of helps everyone find ways to get better and more efficient. As regulations keep tightening, sticking to consistent, reliable filling and sealing is a must. That’s why automation isn’t just a luxury anymore—it’s a key ingredient for making sure everything runs smoothly and efficiently.

Optimization of Production Line with Vial Ampoule Machine

This bar chart illustrates the impact of automation on workflow efficiency in vial filling and sealing processes. The data shows time savings in minutes for each stage of production after implementing a vial ampoule machine.

Industry Standards and Compliance: Ensuring Quality in Vial Ampoule Production

When you're working in the high-stakes world of making vial ampoules, sticking to industry standards and compliance rules really isn't just a good idea — it's everything. From start to finish, every step of the manufacturing process needs to follow those tough guidelines set by health authorities. That’s not just about keeping regulatory bodies happy; it’s about protecting the people who’ll use your products and also boosting the trust others have in your production line.

**A few hints on staying compliant:** Regular audits of your facility are key — they help you spot potential hiccups before they become big problems. Staying up-to-date with the latest rules and weaving them into your daily routines is super important, too. Don’t forget to train your team on good practices and why compliance really matters. It can cut down on mistakes and make the whole operation smoother.

And hey, investing in some cutting-edge technology, like automated vial ampoule machines, can really give you a leg up. These machines often come with cool features that track and record production data in real time — making sure everything stays consistent and reducing human errors. Pretty neat, right?

**A few tips for keeping quality rock-solid:** Having a solid quality management system that covers every part of your process is a must. Regular checks and validation of your equipment help keep the product quality high. And don’t forget to set up a good feedback loop with your team — it’s a simple way to keep improving and make sure you’re always on point with compliance.

Real-Time Performance Metrics: Tracking Production with Vial Ampoule Technology

In today's fast-moving pharma world, keeping an eye on real-time performance metrics is super important for fine-tuning production lines—especially when you're working with advanced equipment like vial ampoule machines. These machines do more than just fill and seal; they also let manufacturers keep tabs on key performance indicators on the fly. When you integrate data analytics into your process, it’s easier to monitor things like throughput, downtime, and potential bottlenecks. And if any issues pop up? You can usually catch and fix them pretty quickly.

Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we totally get how crucial efficiency and accuracy are in pharma manufacturing. We’ve got four dedicated factories, all focused on different sectors—ranging from pharmaceutical machinery to water treatment equipment. We make good use of cutting-edge vial ampoule tech to help optimize operations. By constantly tracking performance data, our clients can make smarter decisions to improve their manufacturing workflows. The result? Better quality products, cost savings, and a leg up in a competitive market. Investing in this kind of tech isn’t just about meeting today’s needs; it’s about positioning your business to grow and thrive down the road.

Future Trends: The Impact of Smart Technologies on Vial Ampoule Machine Optimization

You know, these days, adding smart tech into vials and ampoule machines is really changing the game for production lines in pharma and cosmetics. I came across this report from Grand View Research — it says that by 2027, the whole smart manufacturing scene is forecasted to hit around $1.37 trillion. That’s a huge jump, and a lot of it’s thanks to smarter automation and better data exchange. Basically, manufacturers are now able to tap into data analysis, IoT gadgets, and even AI to boost efficiency and cut down on machine downtime on their vial and ampoule lines.

As this kind of tech becomes more common, you can really see the perks. For example, real-time monitoring gets a lot better — workers can spot issues early on, which means fewer mistakes and wasted resources. McKinsey & Company even found that companies using advanced analytics can bump up their productivity by roughly 20 to 25 percent. Plus, AI-driven predictive maintenance helps extend equipment life and drops service costs. All this points to a future where Industry 4.0 practices are standard — making our vial and ampoule production not just more efficient, but also compliant with the tight regulations we’ve gotta follow in pharma and cosmetics. It’s pretty exciting stuff!

FAQS

: Vial ampoule machines are primarily used in the production of pharmaceuticals and cosmetics, automating tasks such as filling, capping, labeling, and inspection to enhance efficiency and ensure product quality.

There are various types of vial ampoule machines, including rotary vial filling machines for larger batches and linear ampoule filling machines for smaller, specialized products.

They streamline the fill and finish stages of drug production by automating essential tasks, reducing human error, and increasing overall production speeds.

BFS technology is an advanced method that combines the processes of forming, filling, and sealing in a closed system, enhancing sterility during production and providing flexibility in packaging design.

Adhering to industry standards and compliance regulations ensures product quality, safeguards end-user health, and enhances the credibility of the production line.

Regular audits, staying updated on regulations, training employees, and utilizing automated machines with monitoring features can help maintain compliance.

Implementing a robust quality management system, conducting regular quality checks, validating equipment, and establishing feedback loops with staff can sustain product integrity.

Advanced technologies, including automated systems and real-time monitoring features, improve operational efficiency, reduce human error, and help maintain high standards of hygiene and quality.

Training employees on best practices related to compliance and quality assurance can diminish errors, enhance operational efficiency, and promote a culture of quality within the organization.

Automated machines not only increase speed and efficiency but also help ensure adherence to strict hygiene and safety standards, which are critical in the production of injectable substances.

Conclusion

Switching to a Vial Ampoule Machine in your production line really can make a big difference when it comes to efficiency and quality—especially in pharma manufacturing. It’s pretty important to understand the different types and how they’re used because these machines are key players in making the workflow smoother, mainly thanks to automation in filling and sealing vials. Putting one of these machines in place doesn’t just speed things up; it also helps you stay within industry standards, so you know you’re making top-quality ampoules.

Plus, with real-time performance data that these machines provide, manufacturers can keep an eye on how things are going. This makes it easier to tweak and improve the process on the fly—kind of like having a live dashboard. As technology keeps moving forward, we’re probably going to see even smarter, more innovative features added to these machines, shaping the future of automated manufacturing. Companies like Shanghai IVEN Pharmatech are really on top of this stuff, using their know-how to keep ahead of the curve in pharma machinery innovation.

Related Posts

-

The Definitive Handbook to Automated Inspection Machines in the Pharma Industry

-

Mastering the Art of Capsule Filling: A Comprehensive Guide for Global Buyers

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

-

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

-

7 Compelling Reasons to Choose the Best Clean Steam Generator Manufacturers for Your Business Needs

-

How to Choose the Right Syringe Filter Manufacturers for Your Laboratory Needs

Blog Tags: