Revolutionizing Pharmaceutical Production with Advanced Vial And Ampoule Filling Machine Technology

Table of Contents

- Understanding the Role of Advanced Filling Machines in Modern Pharma Production

- Key Features of High-Efficiency Vial and Ampoule Filling Technologies

- Best Practices for Implementing Filling Machine Solutions in Pharmaceutical Facilities

- Ensuring Quality and Compliance in Automated Filling Processes

- Cost-Benefit Analysis of Upgrading to Advanced Filling Machine Systems

- FAQS

- Conclusion

- Related Posts

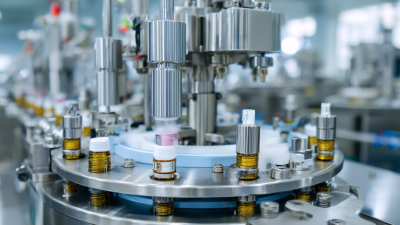

The pharmaceutical world is going through some pretty exciting changes right now, thanks to new tech—especially when it comes to making injectable meds. If you peek at the latest market reports, you'll see that the global market for vial and ampoule filling machines is expected to grow by more than 8% yearly from 2021 to 2028. That’s mostly because there's a rising need for biologics and sterile products.

Shanghai IVEN Pharmatech plays a big part in all this. They’re using some really advanced tech to create high-end filling machines for vials and ampoules. With four dedicated factories focused on pharmaceutical machinery, blood collection tubes, and water treatment setups, they’re pretty well-prepared to meet the demand worldwide. These innovations aren’t just about speeding things up—they also make sure everything is safe and top quality, which ultimately helps improve patient care.

Understanding the Role of Advanced Filling Machines in Modern Pharma Production

In today’s pharmaceutical manufacturing, using advanced filling machines is pretty much a game-changer. These high-tech machines are built to handle a bunch of different containers—like vials and ampoules—and they can automate the whole filling process. What’s cool is how precise they are; thanks to their careful volumetric control, they cut down on mistakes like overfilling or underfilling. That’s a big deal because it keeps everything within strict regulations and also boosts the safety and quality of the products we rely on. Plus, with tech like machine vision, these machines can check each filled container in real-time to spot any issues right away, which adds an extra layer of accuracy.

On top of that, switching to these fancy filling machines really helps make production smoother and faster. Manufacturers can crank out more products quickly and spend less on labor because the machines don’t need as much human oversight. They’re also super flexible and can be easily integrated into existing lines, making it simple to switch between different formulations or container types. That kind of adaptability is pretty crucial since the market nowadays moves fast and consumer preferences change all the time. All in all, adopting this innovative technology is really transforming pharmaceutical production into a more agile, responsive process—leading to better outcomes for patients and everyone involved.

Revolutionizing Pharmaceutical Production with Advanced Vial And Ampoule Filling Machine Technology

This chart illustrates the technological advancements in vial and ampoule filling machines over the years, showcasing their impact on production efficiency and accuracy in the pharmaceutical industry.

Key Features of High-Efficiency Vial and Ampoule Filling Technologies

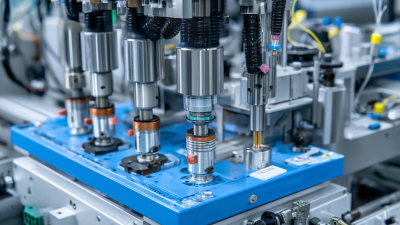

The pharma world is going through a pretty big shift these days, thanks to some really cool new vial and ampoule filling machines. These tech upgrades are a game-changer—they help boost how fast things get produced, make sure everything’s safe and up to standard, and keep up with the skyrocketing demand for injectable meds. If you’ve seen the latest reports from Grand View Research, they’re saying that by 2025, the global market for this kind of equipment could hit around $7.1 billion. That’s mainly because more companies are leaning on biologics and sterile products—they’re just... growing so quickly.

When you look at the key features of these high-tech filling machines, automation, accuracy, and versatility stand out. Automating the process cuts down on human mistakes and speeds things up—think processing thousands of vials or ampoules every hour. Plus, these machines usually come with smart monitoring systems that keep a close eye on fill levels and quality, making sure everything’s consistent. IHS Markit even says that adopting smart manufacturing practices could boost productivity by up to 30%. All these advances don’t just help companies stay compliant with strict regulations—they also make it easier for them to respond quickly when market demands change. Pretty impressive, right?

Best Practices for Implementing Filling Machine Solutions in Pharmaceutical Facilities

In the fast-changing world of pharmaceuticals, having the latest vial and ampoule filling machines is pretty much essential if you want to keep things running smoothly. When it comes to bringing these new machines into your facility, the key is starting with a good look at your current workflows. Spotting where things slow down or bottleneck can really help you customize the setup. That way, the transition is much smoother, and you get the best bang for your buck—more efficiency without messing with quality.

Take Shanghai IVEN Pharmatech Engineering Co., Ltd., for example. They’re really leading the charge in this field, with four specialized factories dedicated to pharmaceutical equipment and more. By tapping into their industry know-how, IVEN can offer tailored filling solutions that fit right into what each client needs. But it’s not just about the machines—proper training for staff and regular maintenance are equally important. These steps are what keep everything running smoothly, so you can see a real boost in your production capabilities without much hassle.

Revolutionizing Pharmaceutical Production with Advanced Vial And Ampoule Filling Machine Technology - Best Practices for Implementing Filling Machine Solutions in Pharmaceutical Facilities

| Parameter | Value | Notes |

|---|---|---|

| Filling Speed | 120 vials per minute | Depends on vial size |

| Accuracy | ±0.5% of fill volume | Critical for potency |

| Cleaning Time | 15 minutes | Automated cleaning systems |

| Downtime | Less than 5% | Includes maintenance |

| Machine Usability | User-friendly interface | Training required for operators |

| Compliance Standards | cGMP | Mandatory for production |

Ensuring Quality and Compliance in Automated Filling Processes

You know, the pharmaceutical production scene has been pretty booming lately. A big reason? There's a huge push for more efficient and automated filling things up — it’s all about speeding things up and keeping quality in check. If you look at the latest industry numbers, the global market for packaging machinery — you know, the tech stuff used in filling vials and ampoules — is projected to hit around 60 billion dollars by 2025. And it’s growing at roughly 5% each year! This surge is mostly because companies and regulators are super focused now on quality and staying compliant, especially as standards get tighter worldwide.

Automation in filling isn’t just about making things faster; it plays a huge role in keeping products safe and effective. Fancy new machines can dial in precise doses, cut down the risk of contamination, and help keep production running smoothly. For pharma companies, dealing with recalls and regulatory fines is a serious headache, so switching to automated filling systems has become kind of a no-brainer. Plus, with high-tech weighing and monitoring gadgets, they can make sure everything’s legit and meet legal standards in real-time — which is a game-changer for maintaining quality. As things develop, it’s clear that new tech in filling processes will be the secret sauce for meeting rising customer expectations while still playing by the tough industry rules.

Cost-Benefit Analysis of Upgrading to Advanced Filling Machine Systems

Upgrading to more advanced vial and ampoule filling machines? Honestly, it's a pretty smart move for pharma companies looking to save a buck while upping their game. As tech keeps moving fast, these new fillers aren't just about faster production — they’re more accurate, more automated, and easier to run. That means less labor fuss, less waste, and ultimately more profit in the pocket. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. get this too; they’re leading the charge with cutting-edge machinery tailored specifically for pharma needs.

Getting these high-tech filling systems in place doesn’t just make things run smoother — it also helps ensure your products are safer and fully compliant with all the regs. Sure, the upfront cost might seem hefty at first, but in the long run, you’re saving on operational costs and boosting your output. In today’s pretty competitive market, adopting such tech can really give a company an edge, while also guaranteeing top-notch quality for their medicines. As the pharma world keeps changing, investing in advanced filling tech feels like a savvy move — perfect for companies that want to stay efficient, competitive, and at the top of their game.

FAQS

: Best practices include conducting a thorough assessment of current workflows, identifying bottlenecks, and tailoring the introduction of filling machinery to enhance productivity while maintaining quality.

Shanghai IVEN Pharmatech Engineering Co., Ltd. is significant due to its four professional factories and expertise in providing customized filling solutions that meet the unique operational needs of pharmaceutical clients.

Effective training for personnel is essential to ensure that the newly implemented machinery operates at peak performance, which significantly enhances production capabilities.

The global market for packaging machinery, including vial and ampoule filling technology, is expected to reach $60 billion by 2025, growing at a CAGR of nearly 5%.

Growth in the pharmaceutical production industry is driven by the rising demand for efficient and automated filling processes and a heightened focus on quality and compliance due to stricter regulatory standards.

Automation enhances operational efficiency by ensuring precise dosage, mitigating contamination risks, and streamlining production lines, which is crucial for maintaining product integrity and safety.

Automated filling systems can help address challenges such as product recalls and regulatory penalties by improving compliance and operational efficiency.

Advanced filling machines often incorporate sophisticated weighing and monitoring devices that provide real-time data essential for quality assurance and compliance with legal requirements.

Technological innovation in filling processes is key to meeting growing consumer demands while adhering to stringent industry regulations, thereby affecting overall production efficiency and quality.

Primary concerns include ensuring quality, maintaining compliance with regulatory standards, and preventing contamination, all of which are critical in the pharmaceutical production process.

Conclusion

So, I came across this article called 'Revolutionizing Pharmaceutical Production with Advanced Vial and Ampoule Filling Machine Technology,' and honestly, it does a pretty good job of showing how much modern filling machines are changing the game for pharma manufacturing. It’s interesting to see how these high-tech vial and ampoule fillers are not only boosting production speed but also helping maintain top-notch quality—something that’s super important in this industry. The article really highlights features like precision, faster throughput, and automation—that sort of thing. Plus, it offers some practical tips on how pharma companies can get these machines up and running smoothly, all while staying compliant with the tricky regulatory stuff.

On top of that, it stresses how crucial quality control is when dealing with automated filling lines. There's also a bit of a breakdown on the costs versus benefits—basically showing that investing in the latest equipment can actually save money in the long run. And it’s exciting to see players like Shanghai IVEN Pharmatech Engineering Co., Ltd. leading the way—these folks really know their stuff. All in all, it feels like the industry is on the brink of some pretty big improvements, and it’s getting more competitive worldwide.

Related Posts

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Ultimate Guide to Choosing the Right Tube Labeling Machine Suppliers for Your Business Needs

-

How to Maximize Production Efficiency with an IV Cannula Making Machine: A Data-Driven Approach

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

How to Select the Perfect Pharma Blister Cartoner Machine for Your Production Needs

Blog Tags: