Understanding the Role of Bioreactor Manufacturers in Sustainable Biotechnology

Table of Contents

- The Importance of Bioreactor Design in Sustainable Biotechnology Applications

- Key Features of Eco-Friendly Bioreactors for Sustainable Practices

- Innovative Materials and Technologies Used by Bioreactor Manufacturers

- Collaboration Between Bioreactor Manufacturers and Biotech Firms for Sustainability

- Regulatory Considerations in the Development of Sustainable Bioreactors

- FAQS

- Conclusion

- Related Posts

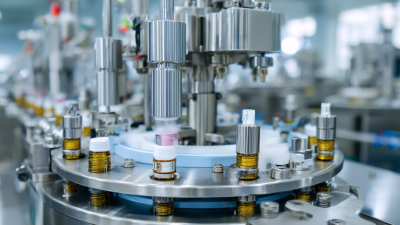

In the fast-changing world of sustainable biotech, the role of Bioreactor Manufacturers has never been more important. As industries scramble to develop greener, more eco-friendly ways of production, companies like Shanghai IVEN Pharmatech are really leading the charge. They've got four specialized factories focusing on everything from pharma machinery to blood collection tubes and water treatment equipment. IVEN is all about coming up with innovative bioreactor solutions that boost efficiency while also cutting down on environmental impact.

By blending cutting-edge tech with sustainable practices, these manufacturers are key players in helping the biotech industry become more eco-conscious and sustainable. In this article, I want to explore how Bioreactor Manufacturers are making a real difference—showing how their expertise is crucial for building a more sustainable future for the industry.

By blending cutting-edge tech with sustainable practices, these manufacturers are key players in helping the biotech industry become more eco-conscious and sustainable. In this article, I want to explore how Bioreactor Manufacturers are making a real difference—showing how their expertise is crucial for building a more sustainable future for the industry.

The Importance of Bioreactor Design in Sustainable Biotechnology Applications

When it comes to advancing sustainable biotech, the way we design bioreactors really matters—especially when we're talking about producing bioactive compounds through cool, innovative methods like solid-state fermentation, or SSF for short. You know, ongoing research shows that SSF makes great use of agro-industrial leftovers, turning what would be waste into something valuable. It's a perfect example of the circular economy in action, proving just how important it is to create bioreactors that are up to the task of supporting such eco-friendly practices.

On top of that, there's a lot of buzz lately about developing new materials and smart tech for making bioreactors more efficient and environmentally friendly. For example, some projects are exploring ways to incorporate advanced manufacturing techniques and bioprocessing know-how—imagine bioreactors built with magnetically controlled smart materials. These kinds of innovations are kind of a game-changer because they help solve current challenges in regulating microbial activity and, in the process, make biotech applications much more sustainable. Ultimately, all these efforts are helping us build a stronger, more resilient bioeconomy that’s better for the planet.

Key Features of Eco-Friendly Bioreactors for Sustainable Practices

You know, in the fast-moving world of biotech, eco-friendly bioreactors are really making a difference when it comes to pushing sustainable practices forward. These smart systems are built with features that aim to cut down environmental impact while still getting the job done efficiently. According to a report from Grand View Research, the global market for bioreactors is expected to hit around $12.69 billion by 2025. That’s mainly because of the rising demand for biopharmaceuticals and everyone’s increasing focus on greener production methods.

One thing that really stands out about eco-friendly bioreactors is how energy-efficient they are. Companies are now adopting cool tech like continuous flow systems and membrane filtration, which, compared to the old-school batch methods, use a lot less energy. For example, a study in the Journal of Cleaner Production pointed out that switching to energy-efficient bioreactors could slash operational costs by up to 20%, plus it helps cut down CO2 emissions. Plus, many of these bioreactors now come with real-time monitoring systems. That means better resource management — keeping conditions just right for microbial growth and reducing waste, which totally aligns with the whole circular economy thing in biotech.

Innovative Materials and Technologies Used by Bioreactor Manufacturers

Bioreactor makers really play a key role when it comes to pushing sustainable biotech forward. They’re always coming up with new materials and technologies to make their products better and more eco-friendly. I read a report from Grand View Research that predicts the global bioreactor market will hit about $8.7 billion by 2027. That’s mainly because there’s a growing buzz around biopharmaceuticals and more sustainable ways of production. One cool trend? Disposable bioreactors made from single-use materials. These not only cut down contamination risks but also help save on costs — which is a win-win for everyone. Plus, companies using these disposable systems are actually shrinking their environmental impact — leaders in the industry are reporting about a 30% reduction in water and energy use during manufacturing, which is pretty impressive.

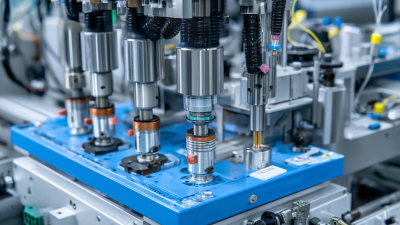

On top of that, there have been some great advances in bioreactor design, especially modular ones that can be scaled up or down depending on what’s needed. For example, a study by the International Society for Pharmaceutical Engineering mentioned that these modular reactors can boost production efficiency by up to 50%. That kind of flexibility lets manufacturers respond faster to market changes and really fine-tune their sustainable practices. Add in real-time monitoring and automation—these tech upgrades give them better control over the process, leading to higher yields and less waste. It’s clear that as bioreactor companies keep innovating with new materials and smarter tech, they’re crucial in driving the whole sector towards a greener, more sustainable future.

Understanding the Role of Bioreactor Manufacturers in Sustainable Biotechnology

| Technology/Material | Description | Sustainability Impact | Application Areas |

|---|---|---|---|

| Single-use Bioreactors | Disposables designed for one-time use, reducing the risk of contamination. | Minimizes waste and energy consumption in cleaning. | Pharmaceutical production, cell culture. |

| 3D Bioreactors | Advanced systems allowing for three-dimensional cell growth to mimic natural environments. | Enhances cell viability and product yield, reducing resource use. | Tissue engineering, regenerative medicine. |

| Smart Bioreactors | Equipped with sensors and IoT capabilities for real-time monitoring and control. | Improves efficiency and reduces resource wastage. | Biopharmaceuticals, biofuels. |

| Biomaterials | Materials derived from renewable resources used in bioreactor construction. | Promotes use of sustainable resources and reduces carbon footprint. | Medical devices, sustainable packaging. |

Collaboration Between Bioreactor Manufacturers and Biotech Firms for Sustainability

You know, the partnership between bioreactor makers and biotech companies really is a big deal when it comes to pushing sustainable biotech practices forward. These manufacturers provide the core technology that biotech firms need to run their processes smoothly, helping them boost product yields while still keeping an eye on the environment. When they incorporate eco-friendly materials and energy-saving designs into their systems, it’s like they’re making it easier to switch to greener ways of production. Honestly, this teamwork can lead to some pretty innovative solutions—things that cut down greenhouse gases and generate less waste, which is pretty awesome.

On top of that, this kind of collaboration isn’t just about equipment—it’s also about sharing knowledge and sparking new ideas to tackle sustainability head-on. Biotech companies often count on these manufacturers’ expertise to tweak and customize their systems for specific uses, like making biofuels, pharmaceuticals, or bioplastics. When they work together on projects or joint research, they can push the envelope—advancing automation, improving monitoring tech, and fine-tuning bioprocesses to be more efficient and sustainable. All in all, this kind of teamwork doesn’t just support eco-friendly innovations; it also shows a real commitment to responsible manufacturing that’s good for both the industry and the planet.

Regulatory Considerations in the Development of Sustainable Bioreactors

Developing sustainable bioreactors is pretty exciting, but it also comes with its own set of regulatory hurdles that manufacturers need to navigate. Honestly, these rules can vary a lot from one part of the world to another, covering things like environmental impact checks, safety measures, and how well the product actually works. So, it’s really important for manufacturers to stay in close touch with regulatory agencies early on—making sure they understand exactly what’s required for their new green tech. The key is to get their designs aligned with these rules right from the start.

On top of that, making bioreactors more sustainable often means we have to rethink some of the old regulations. Using new biomaterials or energy-saving methods might challenge standards that were originally built around older technologies. So, manufacturers really need to push for more flexible, adaptive regulatory approaches that recognize these advances in biotech. The goal is to keep safety and environmental goals front and center, but also to make sure regulation doesn’t hold back innovation. By engaging proactively with regulators, companies can help shape a system that’s more open to new, eco-friendly solutions—and ultimately, that benefits everyone involved in the long run.

Bioreactor Types and Their Sustainability Ratings

FAQS

: Eco-friendly bioreactors are advanced systems designed to minimize environmental impact and maximize efficiency in biotechnology, promoting sustainable practices.

They incorporate technologies like continuous flow systems and membrane filtration, which significantly reduce energy consumption compared to traditional batch processes, potentially lowering operational costs by up to 20%.

Manufacturers increasingly use disposable bioreactors made from single-use materials, which reduce contamination risks and lower operational costs, while significantly minimizing ecological footprints.

Innovations include modular systems that allow for scalability and flexibility, enhancing production efficiency by up to 50% and enabling manufacturers to adapt quickly to market demands.

Real-time monitoring enhances resource management, ensuring optimal conditions for microbial growth, which reduces waste generation and aligns with circular economy principles.

Manufacturers must navigate varying global regulatory frameworks concerning environmental impact assessments, safety protocols, and product efficacy, adapting their designs to meet these regulations.

Close engagement helps manufacturers understand specific requirements for new sustainable technologies and ensures compliance while fostering innovation in bioreactor design.

The adoption of disposable systems has been reported to reduce water and energy consumption during production processes by 30%.

Conclusion

Bioreactor manufacturers are pretty important when it comes to pushing forward sustainable biotech. They’re always working on designing eco-friendly bioreactors that not only boost efficiency but also help cut down on environmental harm. It’s really about using innovative materials and the latest tech to develop bioreactors that can handle the increasing needs of sustainable practices today. Plus, teaming up with biotech companies is a big part of the game—sharing knowledge and resources makes it easier to hit those sustainability goals.

And don’t forget, regulatory stuff plays a huge role in designing these green bioreactors. It guides manufacturers to stick with industry standards, all while promoting environmentally-friendly methods. Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we’re super committed to advancing pharmaceutical machinery and equipment, and that really lines up with these principles of sustainability. It’s clear—manufacturers are key players in building a greener future for biotech, and we’re proud to be part of that movement.

Related Posts

-

Ultimate Guide to Efficient Glas Bottle Packaging Machines for Your Production Line

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

Innovations in Vial Filler Machines at the 138th China Import and Export Fair 2025

-

How to Choose the Best Filling Isolator Line For Your Vial Production Needs

-

Top Strategies for Ensuring the Validation of Capsule Filling Machines in Pharmaceutical Production

-

How to Maximize Production Efficiency with an IV Cannula Making Machine: A Data-Driven Approach

Blog Tags: