What is a Roll Compactor? Key Insights from Top Manufacturers

Table of Contents

- Definition and Functionality of Roll Compactors in Manufacturing

- Key Advantages of Using Roll Compactors for Granulation Processes

- Comparison of Roll Compactor Designs: High-Pressure vs Low-Pressure Units

- Insights into Roll Compactor Efficiency: Data from Leading Manufacturers

- Application Areas of Roll Compactors in Pharmaceutical and Chemical Industries

- Maintenance Practices for Optimal Roll Compactor Performance

- Future Trends and Innovations in Roll Compactor Technology

- FAQS

- Conclusion

- Related Posts

You know, in both the pharma and food worlds, there’s a real push for more efficient ways to break down particles and get better granulation. One of the big players these days is the roll compactor — it’s become a pretty essential piece of equipment on many production lines. Honestly, it helps ensure products come out more consistent, and at the same time, it can cut down on manufacturing costs. I was reading a report from Research and Markets, and it looks like the global market for roll compactors is set to hit around $900 million by 2026. That’s a solid growth rate of about 7.5% every year since 2021, which just shows how important this tech is becoming. It’s clear that understanding what these machines can do — and what manufacturing companies are bringing to the table — is key for anyone in the industry.

Dr. Alan Smith, a real expert in granulation tech, mentioned something interesting: “Getting to grips with the innovative features and efficiency improvements that roll compactors offer is pretty much essential if you're serious about upgrading your production process.” His point underlines just how central these machines are in today’s manufacturing scene. As we take a closer look at the different manufacturers out there, it’s worth digging into the latest advancements and insights driving this market forward — knowledge that can really help stakeholders make smarter choices when it comes to equipment investments.

Definition and Functionality of Roll Compactors in Manufacturing

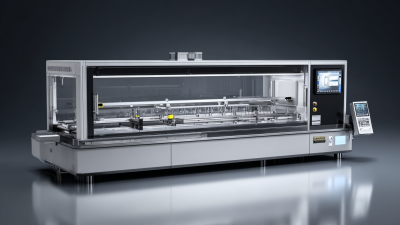

Roll compactors are essential machines in manufacturing processes, primarily used for the compaction of powders and granules. These machines operate on the principle of applying pressure to materials between two counter-rotating rolls, effectively transforming loose powders into dense granules or flakes. This compaction process not only enhances the material density but also improves its flow characteristics, making it easier to handle during subsequent manufacturing stages.

The functionality of roll compactors extends beyond mere compaction. They are also capable of producing uniform particle sizes, which is crucial in industries such as pharmaceuticals, food processing, and chemicals. Additionally, roll compactors can be integrated with other equipment to facilitate wet granulation, enabling the addition of liquid binders during the compaction process. This versatility allows manufacturers to generate a variety of end products while optimizing material properties based on their specific requirements, leading to more efficient production workflows.

Key Advantages of Using Roll Compactors for Granulation Processes

Roll compactors have become an essential tool in the granulation processes across various industries due to their numerous advantages. One of the primary benefits of using roll compactors is their ability to produce uniform granules with consistent particle sizes. This is vital for ensuring that the final product meets the required specifications, particularly in sectors such as pharmaceuticals and food production, where precision in dosing and mixing is crucial.

Moreover, roll compactors are known for their efficiency in processing materials. They can handle a wide range of feed types, transforming powders into dense granules, which not only enhances material flow but also improves packing density. This process minimizes dust generation and increases yield, ultimately leading to cost savings for manufacturers.

Additionally, the continuous operation of roll compactors allows for higher throughput compared to batch processing methods, making them an attractive option for large-scale production environments. Such advantages, combined with their capability to produce high-quality granules, further solidify the role of roll compactors in modern manufacturing processes.

Comparison of Roll Compactor Designs: High-Pressure vs Low-Pressure Units

Roll compactors play a crucial role in various industries, enabling the densification of powders into granules or pellets through a process of compaction. The design of roll compactors can be broadly categorized into two types: high-pressure and low-pressure units, each offering unique advantages based on specific application needs. According to a recent market report from a leading industry analysis firm, the global roll compactor market is projected to grow at a CAGR of 5.1% through 2028, driven by increased demand in pharmaceuticals and food processing sectors.

High-pressure roll compactors generate significant force during the compaction process, often exceeding 200 MPa. This intense pressure leads to the formation of denser materials, which is particularly beneficial for applications requiring precise granule control and enhanced flow properties. Research indicates that high-pressure units can reduce the use of binders, making them an efficient choice for industries focused on reducing production costs and improving material performance. In contrast, low-pressure roll compactors, operating below 100 MPa, are ideal for soft materials that require gentler processing, thus preserving their integrity while achieving a moderate densification.

As manufacturers strive for process optimization, the choice between high and low-pressure roll compactors tends to hinge on the characteristics of the material being processed and the desired end-product specifications. A comparative analysis reveals that high-pressure systems generally yield higher throughput and reduced cycle times, though they may require more substantial initial investments. On the other hand, low-pressure systems offer flexibility and simplicity in operation, making them suitable for a wide range of materials, including friable powders and sensitive constituents. Overall, understanding these distinctions is essential for industries looking to select the right equipment for their production processes.

Insights into Roll Compactor Efficiency: Data from Leading Manufacturers

Roll compactors play a crucial role in enhancing the efficiency of powder processing across various industries. These machines operate by compressing powder materials between two rotating rolls, transforming loose powders into dense, manageable forms. The efficiency of a roll compactor is primarily determined by its design and operational parameters, which include roll surface texture, gap settings, and rotation speeds. Leading manufacturers focus on optimizing these variables to maximize throughput while minimizing energy consumption. This balance is essential for achieving cost-effective production without compromising on product quality.

Data from top manufacturers indicate that advancements in roll compactor technology have led to significant improvements in processing efficiency. Innovations such as enhanced cooling systems and precise control mechanisms enable operators to maintain optimal conditions during compaction. Furthermore, the integration of automation and monitoring systems provides real-time feedback, facilitating adjustments that can enhance performance. As a result, modern roll compactors not only improve throughput but also ensure a higher degree of uniformity in the final product, thus catering to the demanding standards of various industrial applications.

Application Areas of Roll Compactors in Pharmaceutical and Chemical Industries

Roll compactors are essential equipment widely utilized in the pharmaceutical and chemical industries for their ability to process bulk materials into effectively managed forms. These machines employ a dual-roll system to compress powder into dense sheets, which are then broken down into granules or tablets as needed. This process not only enhances the flowability and uniformity of the materials but also significantly improves the consistency of dosage in pharmaceutical applications.

In the pharmaceutical sector, roll compactors play a critical role in granulation processes, where they convert powders into granules that are easier to handle and more conducive to tablet formation. This technique is particularly beneficial for producing formulations that require precise dosage and enhanced bioavailability. Similarly, in the chemical industry, roll compactors are employed for the production of agglomerates and granules, allowing for better control over particle size and distribution. This contributes to the efficiency of downstream processes, such as dissolution and reaction rates, ultimately enhancing product quality and process reliability.

Maintenance Practices for Optimal Roll Compactor Performance

Effective maintenance practices are crucial for ensuring optimal performance and longevity of roll compactors. These machines play a significant role in various industries, especially in the pharmaceutical and food sectors, where precise granulation and compaction are essential. According to a report from Research and Markets, the global roll compactor market is expected to grow at a CAGR of 5.2% from 2021 to 2026, highlighting the increasing reliance on these machines for efficient processing. To maintain peak performance, operators should focus on regular inspections, lubrication of moving parts, and timely replacement of worn components.

An essential aspect of maintenance involves monitoring system parameters such as pressure, temperature, and vibration levels. Implementing a predictive maintenance approach can help identify potential issues before they lead to equipment failure. A study published in the Journal of Manufacturing Science and Engineering suggests that companies employing predictive maintenance strategies save up to 30% in maintenance costs and reduce downtime by approximately 25%. Furthermore, maintaining optimal environmental conditions, such as humidity and temperature, can significantly enhance the performance of roll compactors, as these factors directly influence the material characteristics being processed. Therefore, a diligent maintenance strategy not only enhances efficiency but also contributes to better product quality and operational cost savings.

Future Trends and Innovations in Roll Compactor Technology

The roll compactor technology has been evolving rapidly, driven by the demand for increased efficiency and sustainability in various industries. One of the most significant trends is the integration of advanced automation and process control systems. These innovations allow for real-time monitoring and adjustment of parameters such as pressure and speed, ensuring optimal performance and product consistency. Manufacturers are increasingly utilizing data analytics to predict maintenance needs, reducing downtime and operational costs. The shift towards intelligent systems not only enhances productivity but also supports manufacturers in complying with stringent environmental regulations.

Moreover, there is a growing focus on eco-friendly materials and energy-efficient designs in roll compactor technology. This includes the use of alternative or bio-based materials that minimize environmental impact while maintaining quality standards. Additionally, energy-saving features, such as regenerative braking systems and optimized motor efficiency, are becoming standard in new models. As the industry moves toward more sustainable practices, innovations in roll compactors are expected to play a crucial role in shaping the future of material processing, enabling companies to meet both market demands and ecological responsibilities.

Roll Compactor Technology Trends

This bar chart illustrates the importance level of various trends in roll compactor technology as assessed by industry experts. Key areas include energy efficiency, production rate, material versatility, technological integration, and overall market growth.

FAQS

: Roll compactors compress powder materials between two rotating rolls, transforming loose powders into dense, manageable forms.

The efficiency is influenced by factors such as roll surface texture, gap settings, and rotation speeds, which manufacturers optimize to maximize throughput and minimize energy consumption.

Improvements such as advanced cooling systems, precise control mechanisms, and automation have enabled better performance during compaction.

Automation provides real-time feedback, allowing for adjustments that enhance performance and maintain optimal conditions during compaction.

In the pharmaceutical sector, roll compactors facilitate granulation processes, converting powders into granules that improve handling and dosage consistency.

Roll compactors are used to produce agglomerates and granules, which improve control over particle size and distribution, enhancing downstream processing efficiency.

Achieving a higher degree of uniformity is essential for meeting the demanding standards of various industrial applications, ensuring product quality.

By compressing powders into dense sheets, roll compactors improve the handling properties of materials, which is crucial for effective processing.

Roll compaction significantly improves the consistency of dosage in pharmaceuticals, which is vital for achieving accurate and effective medication formulation.

By ensuring better control over particle size and distribution, roll compaction enhances the efficiency of downstream processes like dissolution and reaction rates.

Conclusion

Roll compactors are essential machinery in manufacturing, particularly for granulation processes in the pharmaceutical and chemical industries. They function by applying pressure to materials, transforming them into granules, thus enhancing their flowability and processing characteristics. The article delves into the advantages of using roll compactors, highlighting their efficiency and versatility, which are crucial for optimizing production.

A comparison of high-pressure and low-pressure roll compactor designs reveals distinct operational efficiencies tailored to specific manufacturing needs. Key insights gathered from roll compactor manufacturers offer valuable data on efficiency and performance metrics. Additionally, the article underscores the importance of maintenance practices to ensure optimal operation and discusses future trends and innovations shaping the evolution of roll compactor technology, indicating a progressive direction for the industry.

Related Posts

-

2025 Top Roll Compactor Manufacturers: Industry Insights & Market Trends

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

-

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

-

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

How to Optimize Your Production Line with a Vial Ampoule Machine

Blog Tags: