How to Select the Perfect Pharma Blister Cartoner Machine for Your Production Needs

Table of Contents

- Key Considerations for Choosing a Pharma Blister Cartoner Machine Based on Production Volume Requirements

- Understanding Different Types of Blister Cartoners: Horizontal vs. Vertical Designs

- Evaluating Speed and Efficiency: Industry Standards for Output Rates in Pharma Production

- Analyzing Material Compatibility: Choosing the Right Cartoner for Various Packaging Materials

- Cost-Benefit Analysis: Initial Investment vs. Long-Term Operational Efficiency in Blister Packaging

- Regulatory Compliance: Ensuring Your Cartoner Meets Pharma Industry Standards and Guidelines

- Innovative Solutions for Efficient Vaccine Delivery: A Comprehensive Guide to Prefilled Syringe Machines

- FAQS

- Conclusion

- Related Posts

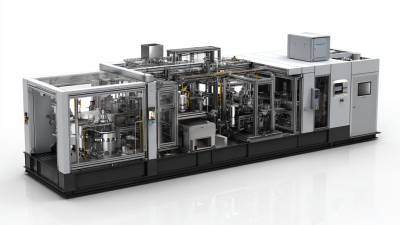

Picking the right Pharma Blister Cartoner machine isn’t just a simple choice — it’s a pretty important decision for any pharma company looking to make their production run smoother and more efficient. Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we totally get how tricky it can be to find that perfect cartoning solution that fits your specific operational needs. We’ve got four dedicated factories doing everything from pharmaceutical machinery and blood tube production to water treatment equipment, so we bring a ton of expertise and innovation to the table.

In this guide, I’ll walk you through the key things to think about when choosing a Pharma Blister Cartoner. The goal? Help you boost efficiency, keep your products safe and intact, and make your packaging process a lot more streamlined. Whether you’re ramping things up or just looking to add more automation, understanding these points should help you make smart decisions that line up with your production goals.

Key Considerations for Choosing a Pharma Blister Cartoner Machine Based on Production Volume Requirements

When you're on the hunt for a pharma blister cartoner machine, one of the most important things to think about is your production volume. You want to make sure it’ll run smoothly and won’t break the bank. So, take a good look at what you’re currently producing and what you expect to produce in the future. If you're a big operation, you might lean toward fully automated machines—they're built for speed and nonstop work. But if you're a smaller outfit, semi-automated options might do the trick—they’re more flexible and usually cheaper upfront.

Also, don’t forget to check how the machine handles different batch sizes and product varieties. It’s handy if the machine has adjustable features to fit different blister pack sizes or carton styles, especially if you carry a diverse line of products. Scalability is another biggie—think about whether it’s easy to upgrade or expand the machine as your production demands grow. That way, you’re not stuck having to buy a whole new setup down the road. And finally, trust me, don’t overlook after-sales support and spare parts availability. These little things can make a huge difference when it comes to keeping your production line running smoothly without unexpected hiccups or costly downtime.

Understanding Different Types of Blister Cartoners: Horizontal vs. Vertical Designs

So, if you're trying to pick out a blister cartoner machine for pharmaceutical manufacturing, it’s pretty important to get a handle on the differences between horizontal and vertical setups. Horizontal blister cartoners are often the go-to if you’re running at high speeds because they have a really efficient layout that keeps the product moving smoothly along. I read in a report from Grand View Research that the global market for blister packaging is expected to hit around USD 26 billion by 2025. That growth is partly because everyone’s craving faster production lines and pushing innovation forward. Plus, horizontal machines tend to be easier to access for maintenance, which cuts down on downtime and keeps things running more smoothly overall.

Now, vertical blister cartoners are a different story. They’re great if you’re working with limited space since they don’t take up as much room, and they’re pretty versatile when it comes to different package sizes. If you’re often changing things up or doing smaller batches, these machines can be a lifesaver. In fact, a study in the Journal of Pharmaceutical Sciences noted that vertical machines could cut production time by about 20%. That’s pretty significant, especially if you want to streamline your workflow and handle a wide range of products without much hassle. Bottom line—understanding these differences can really help you make a smart choice that matches your production goals and needs.

How to Select the Perfect Pharma Blister Cartoner Machine for Your Production Needs

| Feature | Horizontal Blister Cartoner | Vertical Blister Cartoner |

|---|---|---|

| Design Orientation | Horizontal layout for easy access | Vertical layout for compact footprint |

| Production Speed | High-speed capabilities, suitable for large batches | Moderate speed, suitable for medium to large batches |

| Size Flexibility | Can accommodate larger blisters and packages | Ideal for smaller and standard-sized blisters |

| Maintenance | Easier access for maintenance and cleaning | Can be more challenging due to compact design |

| Cost Efficiency | Higher initial cost, but effective for large scale | Lower initial investment, suitable for varied production |

| Operator Training | Requires detailed training for efficient operation | Easier training process with simpler operations |

Evaluating Speed and Efficiency: Industry Standards for Output Rates in Pharma Production

When you're choosing a pharma blister cartoner machine, it’s really important to look at how fast and efficient it is — stuff like this matters a lot in the pharmaceutical world. The machine’s output rate is a big deal because it directly affects how much you can produce in a given time. Of course, there are industry standards to keep in mind, which vary depending on what kind of products you’re packaging and the rules you need to follow. So, you’ve got to ask yourself: can this machine hit those targets without risking the quality of your products?

Plus, the machine’s design and tech features make a huge difference. Modern models might come with cool stuff like automated loading or real-time checks that help keep things running smoothly. When you analyze the output speed along with how well the machine handles different products and packaging needs, you can be pretty confident your operation will stay flexible and ready to adapt. And in a competitive market where time really is money, investing in a blister cartoner that ticks both boxes—speed and efficiency—will not only boost your productivity but also ensure your pharmaceutical products stay safe and effective.

Analyzing Material Compatibility: Choosing the Right Cartoner for Various Packaging Materials

When you're picking out a pharma blister cartoner machine, it's really important to understand the materials you're working with—this can make or break your packaging process. Different meds might need different packaging materials, like PVC, PVDC, or aluminum foil. Each material interacts differently during packaging, so choosing the right cartoner is a big deal. For example, PVC is super common because it’s affordable and pretty clear, but PVDC has better barrier properties, which makes it perfect for more sensitive products. Basically, your cartoner needs to be compatible with whatever materials you’re using to keep everything running smoothly and to protect your products.

And it’s not just about the type of material—things like thickness and shape really matter too. A machine that can handle thicker stuff might need different settings or tooling compared to one designed for thinner films. It’s really worth checking out what the cartoner can do—like its speed, how accurate it folds, and how well it seals—so you know it can handle the specific materials you're using. When you take all these factors into account, you’ll be able to pick a cartoner that not only fits your production needs but also boosts the quality and reliability of your packaging. It’s kinda like finding the perfect fit—it just makes everything work better in the long run.

Cost-Benefit Analysis: Initial Investment vs. Long-Term Operational Efficiency in Blister Packaging

When you're choosing a pharma blister cartoner machine, it’s pretty important to weigh the costs against the long-term benefits. I mean, a recent report by Grand View Research indicates that the global blister packaging market could hit around $32.4 billion by 2025, mainly because there's a growing demand for better pharma packaging solutions. Putting your money into a high-quality cartoner can really pay off — it can boost your production speed, cut down on labor costs, and help reduce product errors. A good machine can up your packaging rate by about 20-30%, making sure you can keep up with market demand without sacrificing quality.

Plus, don’t forget that operational efficiency is key here. It’s all about how well your processes run in the long run. According to Smithers Pira, companies that go for automated blister packaging solutions tend to see their operational costs drop by 15-25% over five years — thanks mostly to less material waste and more accurate production. And honestly, machines that are easy to maintain can make a huge difference by reducing downtime, which is super important for keeping things running smoothly. So, if you find the right balance between the initial investment and these ongoing benefits, your business can really get a leg up in the fast-changing world of pharma manufacturing.

Cost-Benefit Analysis of Pharma Blister Cartoner Machines

Regulatory Compliance: Ensuring Your Cartoner Meets Pharma Industry Standards and Guidelines

When it comes to the pharmaceutical world, choosing the right blister cartoner machine is all about making sure you're playing by the rules. Regulations from big names like the FDA, EMA, and ISO are really important—they help keep products safe and effective. I recently read in Pharmaceutical Technology that around 85% of recalls happen because of labeling mistakes or compliance issues. That really drives home why it’s so crucial to invest in machines built with these standards in mind. A good cartoner should have features like automated inspection systems—these check labels and packaging to catch errors before they become costly problems. It’s all about reducing risks and staying compliant.

Plus, when you're picking out a cartoner, think about whether it can keep up with changing rules. The market for pharmaceutical packaging machines is expected to grow at about 6.9% each year, reaching around $63 billion by 2025—mainly because everyone’s so focused on staying compliant. Machines that are flexible—like programmable settings for different products or sizes—can really help your business stay ahead of those regulatory updates. So, if you keep compliance front and center when making your choice, you’re not just making your operations smoother, but you’re also protecting your reputation and making sure your profits stay healthy in this heavily regulated industry.

Innovative Solutions for Efficient Vaccine Delivery: A Comprehensive Guide to Prefilled Syringe Machines

The advent of prefilled syringes in the 1990s marked a significant breakthrough in the drug packaging and delivery landscape. This innovative solution has transformed the administration of medications, particularly in high-stakes fields such as immunology and surgical procedures within ophthalmology, otology, and orthopedics. According to a report by Grand View Research, the global prefilled syringe market is expected to reach USD 10.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 10.5%. This growth is fueled by the increasing demand for safe and efficient medication delivery methods, which prefilled syringes readily provide.

Prefilled syringes offer numerous advantages, including reduced risk of contamination, precise dosing, and enhanced patient compliance. The packaging and storage of high-grade drugs in these syringes improves the overall efficacy of the treatments while minimizing the potential for error during administration. Furthermore, the World Health Organization emphasizes the significant role these devices play in curbing the spread of infectious diseases, especially in vaccination campaigns where efficiency and safety are paramount.

As the medical industry progresses, the development of cutting-edge prefilled syringe machines is pivotal. These machines not only automate the filling process but also ensure the integrity of the drug throughout its lifecycle. Industry reports indicate that the demand for such advanced machinery will continue to rise, driven by the ongoing need for improved vaccine delivery systems in light of global health challenges. By investing in innovative prefilled syringe technology, medical practitioners can enhance treatment effectiveness and contribute to better health outcomes on a larger scale.

FAQS

: It's essential to assess current and projected production needs. High-volume manufacturers may benefit from fully automated machines for speed, while smaller operations might prefer semi-automated options for flexibility and lower costs.

The machine's capacity, usually measured in cartons per minute, should align with your operational goals to ensure efficiency and effectiveness in production.

Machines that offer adjustable features to accommodate different blister pack dimensions or carton designs are critical for companies with diverse product lines.

Scalability allows the machine to grow with production needs, preventing costly replacements as demand increases.

After-sales support and the availability of spare parts significantly affect production uptime and maintenance costs, making them important considerations.

Different pharmaceutical products may require various packaging materials like PVC, PVDC, or aluminum foil, each affecting the choice of cartoner.

A cartoner must be capable of handling various thicknesses and forms of packaging materials, which may require different mechanical settings or tooling.

Speed, accuracy in folding, and sealing processes are essential attributes that ensure the cartoner can meet the specific requirements of various materials.

Understanding material compatibility ensures efficient operation and maintains product integrity during the packaging process.

Smaller operations may find semi-automated options more affordable with lower upfront costs, while larger manufacturers may invest in automation for long-term efficiency gains.

Conclusion

Picking out the right Pharma Blister Cartoner Machine is pretty important if you want to keep things running smoothly in the pharmaceutical world. Honestly, it helps to think about how much you need to produce – are you better off with a horizontal or vertical model? Sometimes it’s just about what fits best with your setup. Speed matters too, so it’s good to look at industry standards to see what kind of output you’re aiming for and make sure it lines up with your goals. Don’t forget to check if the machine’s compatible with different packaging materials—that way, you’re covered no matter what you’re packing.

It’s also smart to do a bit of a cost-benefit analysis. Like, weigh the upfront costs against long-term efficiency. And of course, staying compliant with all the industry regulations is a must. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. offer a pretty wide range of pharmaceutical machinery, including high-tech Pharma Blister Cartoner Machines. They can really help boost your packaging process without sacrificing quality or safety — pretty important, right?

Related Posts

-

The Future of Liquid Filling Machines: Innovations Shaping Tomorrow's Manufacturing

-

The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

-

How to Choose the Best Filling Isolator Line For Your Vial Production Needs

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

How to Choose the Right Syringe Filter Manufacturers for Your Laboratory Needs

Blog Tags: