Top 10 Tips for Choosing the Right Pharmaceutical Packaging Equipment

Table of Contents

- Understanding the Importance of Pharmaceutical Packaging Equipment

- Identifying the Types of Packaging Equipment Available for Pharmaceuticals

- Evaluating Regulatory Compliance Standards for Packaging Machinery

- Assessing Production Volume and Speed Requirements for Equipment

- Analyzing Cost-Effectiveness and Budget Constraints in Equipment Selection

- Considering Ease of Use and Maintenance in Packaging Equipment

- Exploring Technological Innovations in Pharmaceutical Packaging Solutions

- Efficient Solutions for Packaging: Exploring the Automatic Blister Packing & Cartoning Machine

- FAQS

- Conclusion

- Related Posts

Picking the right pharmaceutical packaging equipment isn't just a technical decision — it's pretty much a big deal for any company in the pharma game. You see, in this industry, where compliance, safety, and efficiency aren’t just buzzwords but absolute essentials, choosing the right gear can really make or break the quality and trustworthiness of your meds. Think of this guide as your friendly walkthrough, packed with useful tips and honest insights to help pharmaceutical pros fine-tune their packaging processes.

As more and more people need medicines, the demand for smart, reliable packaging options keeps climbing too. Good equipment is key to making sure your products stay clean, safe from contamination, and get across to customers in perfect shape. With so many choices out there, figuring out what’s the best fit for your specific needs—like your production scale, the kind of product you handle, and industry rules—can feel pretty overwhelming. But if you keep in mind things like your output volume, the nature of your products, and regulatory standards, you’ll be able to make smarter decisions that boost your entire packaging game.

In the next parts, we’ll go over ten essential tips for choosing the right pharmaceutical packaging machinery. These are best practices that can help you work faster, waste less, and keep your products safer. Getting a grip on these ideas will give your company a real edge — helping you invest in technology that not only handles today’s challenges but also sets you up nicely for future growth.

Understanding the Importance of Pharmaceutical Packaging Equipment

Pharmaceutical packaging equipment plays a vital role in the life cycle of drug products, serving not only as a protective barrier but also as a crucial element in ensuring compliance with rigorous industry standards. The integrity of pharmaceutical products is paramount, as they must be safeguarded from contamination, degradation, and other environmental factors that could compromise their efficacy. Proper packaging preserves the quality of medicines, extends shelf life, and is essential for maintaining patient safety. Understanding the nuances of packaging equipment enables manufacturers to select solutions that align with their specific needs and regulatory requirements.

Furthermore, the efficiency and reliability of packaging equipment can significantly impact operational productivity. As pharmaceutical companies strive to optimize their supply chains and reduce time-to-market, investing in advanced packaging technologies becomes imperative. Options such as automated systems can enhance accuracy, minimize human error, and streamline processes, which leads to better resource management and cost-effectiveness. Ultimately, recognizing the importance of pharmaceutical packaging equipment reinforces the commitment to quality, safety, and innovation within the industry, ensuring that patients receive the highest standard of care.

Identifying the Types of Packaging Equipment Available for Pharmaceuticals

When selecting packaging equipment for the pharmaceutical industry, it’s crucial to understand the various types available, each designed to meet specific requirements in terms of efficiency, safety, and compliance. There are primarily three categories of pharmaceutical packaging equipment: primary, secondary, and tertiary packaging machines. Primary packaging involves direct contact with the product, such as blister packing for pills or vials for liquid medications. Secondary packaging focuses on grouping primary packages, which is often visible on retail shelves, while tertiary packaging is used for bulk transport, ensuring products reach pharmacies and hospitals safely.

A crucial tip for choosing the right packaging equipment is to assess the specific needs of your products, including the volume and type of pharmaceuticals you produce. According to a recent report by Smithers Pira, the global market for pharmaceutical packaging is expected to reach $120 billion by 2025, with significant demand for enhanced safety features and automation. Automation in packaging not only improves efficiency but also reduces human error, which is critical in maintaining compliance with stringent regulatory standards.

Additionally, consider modular systems that can be easily adapted to changing production needs. The flexibility of such systems allows pharmaceutical manufacturers to integrate new technologies without extensive overhauls. This adaptability is highlighted in industry forecasts that estimate a 20% growth in demand for customizable packaging solutions over the next decade. Ultimately, understanding the types of packaging equipment available and making informed choices based on market trends can help ensure long-term success in the pharmaceutical packaging sector.

Evaluating Regulatory Compliance Standards for Packaging Machinery

When selecting pharmaceutical packaging equipment, understanding regulatory compliance standards is crucial. These standards ensure that packaging machinery not only meets the necessary safety and quality measures but also adheres to the guidelines set forth by health authorities. It’s essential to assess how potential equipment aligns with these regulations to avoid costly mistakes and ensure patient safety.

One key tip for evaluating packaging machinery is to thoroughly review the equipment’s compliance with Good Manufacturing Practices (GMP). This includes assessing the materials used in the machinery, as they must not react negatively with the pharmaceuticals being packaged. Additionally, it's important to verify that the machinery is designed for clean environments to minimize contamination risks.

Another valuable consideration is the equipment’s validation and documentation processes. Ensure that the machinery comes with robust validation protocols that meet regulatory expectations, such as installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ). This documentation not only aids in compliance but also provides assurance of the equipment's reliability and efficiency in a pharmaceutical setting.

Top 10 Tips for Choosing the Right Pharmaceutical Packaging Equipment

| Tip No. | Tip Description | Regulatory Compliance Standard | Key Considerations |

|---|---|---|---|

| 1 | Assess Material Compatibility | USP ISO 11607 |

Consider chemical interactions and stability. |

| 2 | Evaluate Equipment Reliability | FDA 21 CFR Part 820 | Look for proven track records and warranties. |

| 3 | Check for Scalability | GMP Guidelines | Ensure it can handle future production increases. |

| 4 | Compliance with Labeling Requirements | FDA Labeling Regulations | Verify equipment can print and apply accurate labels. |

| 5 | Consider Automation Options | ISO 9001 | Evaluate labor reduction and efficiency gains. |

| 6 | Assess Cleaning and Maintenance Needs | FDA 21 CFR Part 210 | Look for easy access and less downtime. |

| 7 | Evaluate Supplier Support | FDA Support Requirements | Assess training and troubleshooting options. |

| 8 | Review Cost-Effectiveness | CFR Part 210 Financial Guidelines | Examine ROI and total cost of ownership. |

| 9 | Test for Ergonomics | ISO 45001 | Ensure safety and comfort for operators. |

| 10 | Stay Informed on Regulations | Global Regulatory Standards | Keep up with changes in compliance requirements. |

Assessing Production Volume and Speed Requirements for Equipment

When selecting pharmaceutical packaging equipment, one of the most critical factors to consider is the production volume and speed requirements. The pharmaceutical industry is witnessing an increasing demand for high-efficiency packaging solutions driven by the need for faster time-to-market. According to a 2021 report by MarketsandMarkets, the pharmaceutical packaging market is projected to reach USD 1.3 trillion by 2027, underscoring the necessity for manufacturers to upgrade their packaging processes to meet rising demands.

Production volume directly influences the type of packaging equipment a company should invest in. For instance, manufacturers with a high throughput requirement may require fully automated systems that can handle large batches with minimal downtime. In contrast, smaller-scale operations could benefit more from semi-automated or manual systems, which provide the flexibility to adapt to varying production quantities. A study from PMMI indicates that 50% of respondents reported increasing their automation levels to enhance productivity and reduce labor costs. These insights suggest that businesses must accurately assess their expected production volumes and select equipment that aligns with their operational capabilities and market expectations.

Moreover, speed requirements should not be overlooked, as they are critical to maintaining competitiveness in a rapidly evolving industry. Packaging lines need to be agile, capable of adjusting to changes in product features without significantly impacting overall productivity. According to a report by IDTechEx, the push for smart packaging technologies is on the rise, with over 60% of pharmaceutical companies indicating that they plan to implement more advanced packaging solutions over the next few years. This trend highlights the importance of investing in equipment that offers scalability and the ability to integrate advanced technologies, ensuring that manufacturers remain responsive to market demands while upholding high standards of quality and compliance.

Analyzing Cost-Effectiveness and Budget Constraints in Equipment Selection

When selecting pharmaceutical packaging equipment, cost-effectiveness and budget constraints play a critical role in the decision-making process. A thorough analysis of the total cost of ownership (TCO) is essential to determine the long-term financial implications of any equipment investment. This includes not only the initial purchase price but also factors such as maintenance costs, energy consumption, and potential downtime. Prioritizing equipment that offers a favorable TCO can help pharmaceutical companies optimize their financial resources while ensuring compliance with industry standards.

Additionally, it is crucial to establish a clear budget before exploring packaging options. This budget should account for all anticipated expenses, including installation, training, and ongoing operational costs. Engaging in a cost-benefit analysis can help stakeholders evaluate different equipment options against their budgetary limits. By identifying the essential features that provide the greatest return on investment, companies can make informed decisions that align with both their financial goals and operational requirements. This strategic approach not only supports financial viability but also enhances overall productivity and efficiency in the pharmaceutical packaging process.

Considering Ease of Use and Maintenance in Packaging Equipment

When selecting pharmaceutical packaging equipment, ease of use and maintenance are critical factors that can significantly impact operational efficiency. A user-friendly machine is essential for ensuring that staff can quickly learn to operate it without extensive training. Equipment with intuitive interfaces and clear instructions not only enhances productivity but also minimizes the risk of errors during the packaging process. Simplicity in design can help streamline workflows, enabling operators to focus on quality control rather than struggling with complicated machinery.

Maintenance is another crucial consideration that plays a vital role in the longevity and performance of packaging equipment. Choose equipment that allows for straightforward cleaning and servicing, which can save time and reduce downtime in production. Moreover, consider the availability of spare parts and support services, as these will affect the overall maintenance ease. Regular maintenance can prevent unexpected breakdowns and ensure compliance with safety and quality standards. In essence, prioritizing these attributes can lead to more reliable and efficient packaging operations in the pharmaceutical industry.

Exploring Technological Innovations in Pharmaceutical Packaging Solutions

In the fast-evolving landscape of pharmaceutical packaging, technological innovations play a pivotal role in enhancing efficiency, safety, and compliance. Recent industry reports estimate that the global pharmaceutical packaging market will reach USD 100 billion by 2025, driven significantly by advancements in packaging machinery. Automation has become a cornerstone of these innovations, with smart packaging solutions integrating IoT technology to track products throughout the supply chain, ensuring that they meet safety standards while minimizing waste.

Moreover, cutting-edge techniques such as blister packaging and active packaging are gaining traction. Blister packs not only improve shelf life but also allow for precise dosage control, which is crucial in maintaining drug efficacy. Active packaging incorporates materials that can interact with the product or its environment, providing real-time data and extending product longevity. According to a report by Smithers Pira, these technologies are expected to reduce packaging waste by about 13% over the next five years, aligning with global sustainability goals and significant reductions in environmental impact.

As manufacturers explore these advancements, the importance of choosing the right packaging equipment becomes paramount. Efficient machinery not only streamlines the filling and sealing processes but also enhances the overall reliability and quality of pharmaceutical products. With the integration of cutting-edge technology, pharmaceutical companies are better equipped to meet regulatory requirements and consumer demands, paving the way for innovative packaging solutions that prioritize safety and efficiency.

Top 10 Tips for Choosing the Right Pharmaceutical Packaging Equipment

Efficient Solutions for Packaging: Exploring the Automatic Blister Packing & Cartoning Machine

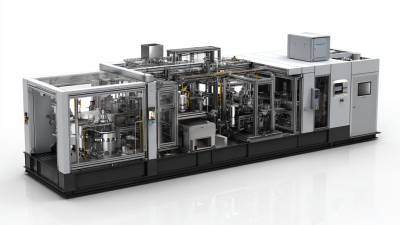

The automatic blister packing and cartoning machine is revolutionizing packaging efficiency across various industries, reflecting a growing trend towards automation. This line typically integrates three essential machines: the blister machine, the cartoner, and the labeller. The blister machine is designed to form blister packs from thermoformed plastics, which offer a protective solution that ensures product integrity. According to a recent market report, the global blister packaging market is projected to reach $22.4 billion by 2026, growing at a CAGR of 6.2%. This highlights the increasing demand for blister packaging solutions, driving investments in automated systems.

Following the blistering process, the cartoner plays a critical role in packaging these blister packs into cartons, efficiently preparing them for distribution. The cartoning machine enhances productivity by automating the packaging of multiple blister packs into a single carton, reducing labor costs and improving speed. Reports indicate that automation in packaging can improve line efficiency by up to 30%, significantly impacting operational costs. Furthermore, the labeller adds an important finishing touch by applying labels to cartons, ensuring compliance with regulatory standards and increasing brand visibility.

The integration of these machines not only boosts efficiency but also provides manufacturers with greater flexibility. In an era where consumer preferences are rapidly changing, having an adaptable packaging process is essential. As supply chains continue to evolve, the adoption of automatic blister packing and cartoning machines represents a strategic investment for businesses looking to enhance their packaging operations and meet the demands of the marketplace.

FAQS

: Pharmaceutical packaging equipment is crucial for protecting drug products, ensuring compliance with industry standards, preserving medicine quality, extending shelf life, and maintaining patient safety.

The main categories are primary packaging (direct contact with the product), secondary packaging (grouping primary packages), and tertiary packaging (used for bulk transport).

Automation enhances accuracy, minimizes human error, streamlines processes, and improves efficiency, ultimately leading to better resource management and cost-effectiveness.

Analyzing TCO helps companies understand the long-term financial implications of equipment investments, including initial purchase price, maintenance costs, energy consumption, and potential downtime.

Establishing a clear budget helps account for installation, training, and ongoing operational costs, ensuring that companies make informed decisions that align with their financial goals.

Companies should assess specific product requirements, including the volume and type of pharmaceuticals they produce, and consider flexibility in systems that allow adaptation to changing production needs.

The demand for customizable packaging solutions is projected to grow by 20% over the next decade, highlighting the need for flexibility within packaging systems.

Investing in reliable and efficient packaging equipment can significantly impact operational productivity by optimizing supply chains and reducing time-to-market for pharmaceutical products.

A cost-benefit analysis should evaluate different equipment options against budgetary limits by identifying essential features that provide the greatest return on investment.

Trends like enhanced safety features, automation, and the need for compliance with stringent regulatory standards are shaping the future of pharmaceutical packaging.

Conclusion

Choosing the right Pharmaceutical Packaging Equipment is crucial for ensuring product safety and compliance within the industry. Understanding the importance of packaging equipment involves recognizing its role in maintaining the integrity of pharmaceuticals and adhering to strict regulatory compliance standards. Various types of packaging equipment are available, each suited to different production volumes and speeds, which must be carefully assessed based on specific operational needs.

Cost-effectiveness and budget constraints are also significant factors that influence equipment selection. Additionally, ease of use and maintenance should not be overlooked, as these aspects can impact overall efficiency. Finally, exploring technological innovations in pharmaceutical packaging solutions can lead to advancements that enhance productivity and reliability within the packaging process, ultimately supporting the industry's mission to deliver safe and effective medications.

Related Posts

-

Explore the Future: 2025 Top Pharmaceutical Packaging Equipment Innovations

-

How to Select the Perfect Pharma Blister Cartoner Machine for Your Production Needs

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

How to Optimize Production Efficiency with a Single Dose Packaging Machine

-

2025 How to Choose the Best Pharmaceutical Liquid Filling Machine for Your Needs

-

How to Choose the Best Filling Isolator Line For Your Vial Production Needs

Blog Tags: