Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

Table of Contents

- Understanding Blow Fill Seal Technology and Its Advantages

- Key Features of Modern Blow Fill Seal Machines

- Streamlining Production: How Blow Fill Seal Machines Improve Efficiency

- Cost-Effectiveness: The Financial Benefits of Implementing BFS Systems

- Quality Control: Ensuring Product Integrity with BFS Technology

- Future Trends: Innovations in Blow Fill Seal Machine Design and Application

- Enhancing Safety and Efficiency: A Comprehensive Overview of BFS (Blow-Fill-Seal) Solutions for IV Products Based on Recent Industry Insights

- FAQS

- Conclusion

- Related Posts

You know, in today’s fast-changing world of manufacturing, embracing new tech is honestly key to making things run smoother and cranking out better quality products. One game-changer in this space has been the Blow Fill Seal Machine. It’s really shaken up how packaging is done, especially in pharma. I came across a market report recently, and it’s pretty exciting—these machines are expected to grow a lot, with the market hitting around around $6.5 billion by 2025. That’s mainly because everyone’s asking for sterile, efficient packaging now more than ever. At Shanghai IVEN Pharmatech, we totally get how powerful this tech is. With our four expert factories, we’re proud to supply top-notch pharmaceutical machinery—including those awesome Blow Fill Seal Machines. By using this technology, manufacturers can simplify their processes, cut down contamination worries, and ultimately get better products into the hands of consumers—pretty cool, right?

Understanding Blow Fill Seal Technology and Its Advantages

Blow Fill Seal (BFS) technology is really changing the game when it comes to how products are made, especially in pharma and food sectors. It’s pretty amazing how this modern process combines forming, filling, and sealing containers all in one go. That means less fuss about contamination and a big bump in production speed — always a win, right? According to a report from Mordor Intelligence, the global BFS market is expected to grow at around 6.4% annually between 2021 and 2026. This just shows how more and more companies are seeing the value and safety benefits that BFS offers.

Over here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we’re really proud to be leading the charge with our top-of-the-line BFS machines. We have four specialized factories dedicated to different kinds of pharma machinery, so we can really ensure our solutions meet the highest standards in the industry. BFS isn’t just about cutting costs — it also helps make sure every product is consistent thanks to its precise filling process. So, if you’re a manufacturer looking to tighten things up and improve efficiency, BFS is definitely worth considering.

Here's a little tip: When you’re thinking about adopting BFS technology, it’s smart to look at how well the equipment can grow with your business down the line. Also, check if it’ll play nicely with your existing production setup—nothing worse than a clunky transition! Going all in on BFS can really save you money long-term and boost the quality of your products. It’s pretty much a no-brainer for modern manufacturing.

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

The following chart illustrates the efficiency gains and advantages of Blow Fill Seal (BFS) technology in modern manufacturing, highlighting the reduction in production time, cost, and material waste.

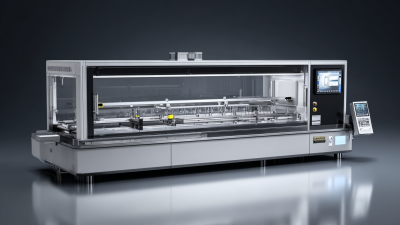

Key Features of Modern Blow Fill Seal Machines

Blow Fill Seal (BFS) machines have really changed the game in manufacturing, especially in pharma and food sectors. One of the coolest things about modern BFS machines is that they can make sterile containers right from plastic granules—all in one go. This inline process not only cuts down on contamination risks but also speeds things up quite a bit. Plus, with smart tech like automated handling and precise temperature controls, every container gets filled and sealed with a high level of accuracy and consistency. It’s pretty impressive.

And you know what else? These machines are super versatile. They can handle all sorts of container shapes and sizes, which makes them perfect for different market needs. They’re also designed to scale up easily, so manufacturers can boost production without sacrificing quality. On top of that, their compact build means they don’t take up too much space—something that’s a real plus for busy manufacturing facilities. All in all, the features of today's BFS machines really make a difference in running things smoothly and ensuring products are safe and top-notch.

Streamlining Production: How Blow Fill Seal Machines Improve Efficiency

Blow Fill Seal (BFS) machines are really changing the game when it comes to manufacturing. They combine forming, filling, and sealing all in one smooth process—kind of like a one-stop shop—which cuts down on extra handling and helps keep things contamination-free. That means faster production times and consistently good quality products, making BFS especially popular in fields like pharma and cosmetics.

Blow Fill Seal (BFS) machines are really changing the game when it comes to manufacturing. They combine forming, filling, and sealing all in one smooth process—kind of like a one-stop shop—which cuts down on extra handling and helps keep things contamination-free. That means faster production times and consistently good quality products, making BFS especially popular in fields like pharma and cosmetics.

If you're looking to get the most out of BFS tech, a few tips might help. First off, make sure to do regular maintenance checks—keeps the machines running smoothly and can save you from unexpected breakdowns. Also, investing some time in training your operators is a good idea. When they really get how the machinery works, they can handle issues quicker and tweak processes to get even better results.

Lastly, don’t forget about the materials you’re using for packaging. Picking the right materials that play nicely with BFS can improve how well seals hold up and even extend the shelf life of your products. Focus on these areas, and you’ll harness the full potential of BFS machines, powering up your production line like a pro.

Cost-Effectiveness: The Financial Benefits of Implementing BFS Systems

The manufacturing world is changing pretty quickly these days, and Blow Fill Seal (or BFS) machines are right in the middle of it all. I came across a report from MarketsandMarkets that predicts the BFS tech market will hit around $3.2 billion by 2025, growing at about 7.4% annually. The main reason? These systems help cut costs big time. By handling mixing, sealing, and sterilizing all in one automated process, factories can slash their labor expenses — we're talking potentially saving up to 20% on day-to-day operations.

Plus, BFS machines are super efficient when it comes to material use. They fill containers precisely, which means less waste and lower product costs. There was even a study from the International Society for Pharmaceutical Engineering saying that switching over to BFS could save companies over 15% on packaging costs because it reduces how much resin is needed for each container. And let’s not forget, the consistent quality and dependability of BFS help produce better products, which means fewer recalls and happier customers. All in all, investing in Blow Fill Seal technology isn’t just a smart move—it’s a strategic step toward making manufacturing more cost-effective in the long run.

Quality Control: Ensuring Product Integrity with BFS Technology

You know, the arrival of Blow Fill Seal (BFS) technology has really changed the game when it comes to quality control, especially in pharma and food industries. Basically, it combines the blowing, filling, and sealing steps all into one smooth process. That means there's a lot less chance for contamination to sneak in. It’s pretty cool because products get filled in a sterile environment, which not only keeps them safe but also helps build trust with the consumers—they can feel confident about what they’re buying.

Plus, BFS tech gives manufacturers great control over the filling process and the final quality of the product. Since it’s a closed system, there’s less human handling involved, which cuts down on mistakes. You’ve also got real-time monitoring and automated data collection, so keeping everything up to scratch becomes much easier. It’s like having an extra set of eyes constantly watching, making sure every single unit meets the standards. Honestly, if you’re serious about producing top-notch products in today’s world, jumping on the BFS bandwagon is definitely a smart move. It’s all about safety and quality, after all—things that consumers really care about these days.

Future Trends: Innovations in Blow Fill Seal Machine Design and Application

Lately, there’s been quite a lot of exciting changes in how Blow Fill Seal (BFS) machines are designed and used. It’s pretty amazing to see how these machines are becoming smarter and more efficient. For instance, more and more of them now come with really advanced automation features, which not only make the whole manufacturing process smoother but also boost precision when filling and sealing. Some of the leading-edge BFS machines even connect to the internet — I mean, IoT-enabled — so they can be monitored in real-time, with data analysis that helps run things more efficiently and cut down on unexpected downtime. Pretty cool, right?

On top of that, there’s a real focus these days on making everything more sustainable. Manufacturers are really pushing for eco-friendly materials and greener practices — like using biodegradable polymers in packaging, for example. It’s not just about being environmentally responsible, but also about meeting what consumers want. Companies are aiming to hit those sustainability goals, you know? As BFS technology keeps evolving, we’re seeing it being adopted more and more in sectors like pharma, food and beverages, and cosmetics. And with these advancements, we’ll probably see even more innovative solutions popping up, balancing market demands with environmental concerns — which is kinda exciting, don’t you think?

Enhancing Safety and Efficiency: A Comprehensive Overview of BFS (Blow-Fill-Seal) Solutions for IV Products Based on Recent Industry Insights

The adoption of Blow-Fill-Seal (BFS) technology for intravenous (IV) and ampoule products marks a significant advancement in the medical delivery system, enhancing both safety and efficiency. Recent industry insights reveal that hospitals utilizing BFS solutions have reported a 30% reduction in medication errors, attributable to the precision of the BFS system in delivering consistent dosages. This state-of-the-art technology applies sophisticated algorithms to ensure medications are not only delivered safely but also optimally, minimizing waste and exposure to contamination.

Moreover, the BFS system stands out for its user-friendly design, requiring minimal training for healthcare professionals. A survey conducted by a leading healthcare consulting firm indicated that over 85% of users found the BFS system easy to operate, which aligns with the growing demand for streamlined processes in medical environments. As the healthcare sector seeks effective solutions that meet budget constraints, BFS technology emerges as a cost-effective option, with reported savings of up to 25% on traditional packaging and delivery methods.

The shift towards BFS solutions underscores a broader trend in the industry aimed at leveraging technology to enhance care delivery. As the globally recognized market for BFS products is projected to grow at a CAGR of 11% through 2026, the implications for hospitals and clinics are profound, enabling improved patient outcomes while maintaining affordability in an increasingly competitive healthcare landscape.

FAQS

: Modern Blow Fill Seal machines produce sterile containers directly from plastic granules, minimizing contamination risk and reducing production time. They incorporate automated handling systems and precision temperature controls for accurate filling and sealing.

BFS machines combine forming, filling, and sealing in one operation, reducing additional handling and contamination risks, which accelerates the production cycle and ensures consistent product quality.

BFS technology is ideal for industries such as pharmaceuticals and cosmetics, where contamination prevention and consistent quality are crucial.

Yes, modern BFS machines are versatile and can handle a wide range of container shapes and sizes to meet various market demands.

Manufacturers can improve efficiency by conducting regular maintenance checks, investing in operator training, and choosing compatible packaging materials.

The compact design of BFS systems saves floor space in manufacturing facilities while maintaining high throughput rates, contributing to overall operational efficiency.

Operator training ensures that staff are knowledgeable about the machine's functionalities, allowing them to quickly address issues and optimize production processes, thus enhancing efficiency.

Advanced technologies, such as automated systems and precision controls, improve accuracy and consistency in the filling and sealing process, resulting in higher product safety.

Selecting suitable packaging materials that are compatible with BFS technology can improve seal integrity and extend the shelf life of products.

To maximize BFS benefits, manufacturers should maintain regular machine checks, provide adequate operator training, and evaluate packaging materials for compatibility with BFS processes.

Conclusion

You know, in today's world of manufacturing, the Blow Fill Seal Machine really stands out as a real game-changer. It’s helping industries boost their efficiency and ramp up their production capacity, all while making things smoother and quicker. Honestly, these machines pack a lot of features that not only speed things up but also keep quality control top-notch. That way, you’re sure the product stays perfect from start to finish during packaging.

And let’s not forget the cost savings—they really make a difference. Investing in a Blow Fill Seal system can be a smart move for companies wanting to optimize their operations without breaking the bank. Looking ahead, there are so many exciting innovations on the horizon in how these machines are designed and used. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are leading the charge, pushing the boundaries of what's possible in pharmaceutical equipment. Jumping on these advances will definitely give you a leg up, helping your business stay competitive and succeed in today’s fast-paced manufacturing world.

Related Posts

-

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

-

The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

-

Ultimate Guide to Efficient Glas Bottle Packaging Machines for Your Production Line

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

-

Top Strategies for Ensuring the Validation of Capsule Filling Machines in Pharmaceutical Production

Blog Tags: