The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

Table of Contents

- Understanding the Blow Fill Seal Manufacturing Process and Its Advantages

- Key Industry Trends Impacting Blow Fill Seal Manufacturers in 2023

- Top Factors to Consider When Choosing a Blow Fill Seal Manufacturer

- Comparative Analysis of Leading Blow Fill Seal Manufacturers in the Market

- Essential Certifications and Quality Standards for Blow Fill Seal Production

- Cost-Benefit Analysis: Investing in Blow Fill Seal Technology for Your Business

- FAQS

- Conclusion

- Related Posts

You know, in the fast-changing world of pharmaceuticals, staying efficient and safe isn’t just important — it’s everything. That’s why advanced packaging solutions are in such high demand right now. One tech that’s really making waves is Blow Fill Seal (BFS) — it’s kind of like the go-to for manufacturers who want to keep their products top-notch and make their production lines run smoother. I recently came across a report from MarketsandMarkets that says the global BFS market is expected to hit around USD 7.48 billion by 2026, growing at an impressive rate of about 11.2% CAGR. As this industry keeps booming, it becomes super important to find reliable, skilled BFS manufacturers who can deliver quality and stick to all the regulatory standards. That’s where companies like Shanghai IVEN Pharmatech come in — they’ve got four factories focused specifically on pharma machinery, including BFS tech, ready to meet the rising demand and help develop innovative solutions for today’s healthcare needs.

Understanding the Blow Fill Seal Manufacturing Process and Its Advantages

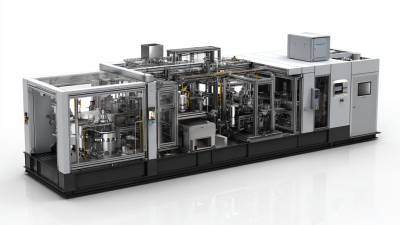

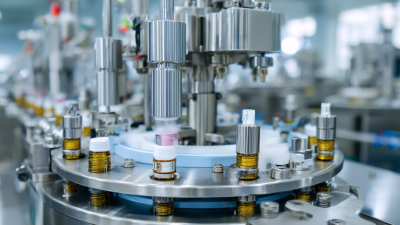

The Blow Fill Seal (or BFS, for short) process is pretty innovative—it's mostly used in pharma and food manufacturing. Basically, it combines three main steps: shaping the plastic containers through blow molding, filling them up, and sealing them all in one smooth, automated go. The journey starts with creating a plastic shell from resin. Once that's done, the machine fills the container with whatever product you’re making—like liquid medicine or food—while keeping everything super sterile. Then, the container is sealed shut to keep out germs and make sure the product stays fresh and safe.

The Blow Fill Seal (or BFS, for short) process is pretty innovative—it's mostly used in pharma and food manufacturing. Basically, it combines three main steps: shaping the plastic containers through blow molding, filling them up, and sealing them all in one smooth, automated go. The journey starts with creating a plastic shell from resin. Once that's done, the machine fills the container with whatever product you’re making—like liquid medicine or food—while keeping everything super sterile. Then, the container is sealed shut to keep out germs and make sure the product stays fresh and safe.

One of the coolest parts about BFS is that it can create sealed, sterile packaging, which is huge when safety and cleanliness are such big deals. It really helps cut down on the risk of contamination during production. Plus, it’s pretty efficient—doing all these steps in one go means less manual handling and less cleaning needed, which translates to lower costs. Because of all these perks, BFS is a pretty popular choice for companies that want to produce high-quality stuff while sticking to strict safety rules. It’s a game-changer, no doubt.

Key Industry Trends Impacting Blow Fill Seal Manufacturers in 2023

Hey there! So, 2023 has been quite a year for Blow Fill Seal (BFS) manufacturers. A lot of trends are cropping up that are really shaking up the industry. One big thing everyone’s talking about is the huge push toward sustainable packaging. If you haven't heard, a report from Smithers Pira mentions that the global market for eco-friendly packaging is expected to hit a whopping $1 trillion by 2027. Crazy, right? This shift is pushing BFS producers to get creative—coming up with greener materials and cleaner processes to cut down their environmental impact.

On top of that, automation and smart tech are taking center stage. According to the International Federation of Robotics, the use of industrial robots in factories is forecasted to grow by about 15% each year over the next five years. That kind of growth means companies can boost their efficiency and keep quality high—two things that matter a lot in today’s competitive market. Companies that jump on these tech trends now are probably going to stand out from the crowd.

If you're looking to stay ahead, I’d suggest trying out biodegradable materials in your BFS line—customers who care about the environment will really appreciate it. Also, investing in smart manufacturing tech can help you run things more smoothly and save money in the long run. It’s a good idea to keep an eye on industry reports, so you stay in the loop with new trends and tech that could give your business a boost. Trust me, staying informed is key!

Top Factors to Consider When Choosing a Blow Fill Seal Manufacturer

When you're choosing a blow fill seal (BFS) manufacturer, there are a few important things you really want to keep in mind — stuff that can seriously impact how well and how smoothly your packaging process goes. First off, take a close look at their experience and expertise with BFS technology. A company that’s been around the block a few times probably knows the ins and outs, and can handle the quirks of your specific products. That way, you can feel confident your packaging will hit all the safety and quality marks.

Plus, don’t forget to check out their production capabilities and the equipment they use. Modern machinery isn’t just about looking shiny — it means they can do precise work and adapt to different packaging needs and product specs. And, of course, ask about their quality assurance processes. A solid quality control system is key to keeping things consistent, avoiding contamination, or packaging blunders.

If you focus on these points, you’ll be better equipped to find a BFS partner that really lines up with what you need and helps you reach your business goals.

Comparative Analysis of Leading Blow Fill Seal Manufacturers in the Market

When you're trying to pick the best blow fill seal (BFS) manufacturers, doing a thorough comparison really pays off. I came across a recent market report from Fortune Business Insights, and it shows that the global BFS market hit around $4.2 billion back in 2022. What's even more interesting is that it's expected to grow at about 7.5% annually until 2029. This really highlights how important BFS technology is becoming—especially in pharma and food sectors—where people are super particular about sterile, preservative-free packaging.

Now, when you look at the big players like Estee Lauder, Rommelag, and Bosch, they really stand out—mainly because they’re pushing the envelope with innovative tech and a solid focus on quality. For example, Rommelag’s BFS systems can cut cycle times by up to 30%, which means they can pump out more bottles without sacrificing sterility. Plus, according to another report I read from Research and Markets, companies that adopt more automation in their BFS processes can cut operational costs by as much as 25%. So, if you’re evaluating which manufacturer to go with, it’s not just about their production capacity, but also about the latest tech and how much money you could save by choosing smarter, more efficient options.

Essential Certifications and Quality Standards for Blow Fill Seal Production

Looking for the best Blow Fill Seal (BFS) manufacturers? Well, understanding the key certifications and quality standards they should have is super important. These certifications basically show that the manufacturer is following industry rules and maintaining top-notch quality in their production. For example, ISO 9001 is all about quality management systems, helping companies keep things consistent, while ISO 13485 is more focused on medical devices—crucial for healthcare products. These standards help streamline processes, cut down on risks, and ensure that BFS products are reliably good every time.

On top of that, sticking to Good Manufacturing Practices (GMP) is a must. GMP guidelines make sure that the manufacturing process is safe and up to standard — which, let’s be honest, is pretty critical when it comes to pharmaceuticals and food items. Plus, manufacturers should also make sure they’re compliant with local laws and hold certifications relevant to what they’re producing. All this effort shows they’re serious about quality and safety, giving clients peace of mind knowing they’re getting dependable, safe BFS solutions. It’s all about trusting the process—and the product.

Cost-Benefit Analysis: Investing in Blow Fill Seal Technology for Your Business

You know, Blow Fill Seal (BFS) technology has really shaken things up in the pharmaceutical packaging world. It's a pretty slick way to produce and fill containers — all under sterile, aseptic conditions. As safety and efficiency become bigger deals when it comes to drug delivery, the BFS market is actually on the rise. A recent report predicts it’ll hit around USD 8.6 billion by 2027, growing at about 8.4% CAGR. What’s great about this tech? It not only helps keep the product intact and safe, but it also cuts down on manual handling, which means a smaller chance of contamination. Pretty cool, right?

If your company is thinking about investing in BFS, it’s a smart move to do a solid cost-benefit analysis first. Sure, the upfront costs can be quite steep, but in the long run, you might end up saving a lot — from lower labor costs and less waste to extending your product’s shelf life. Plus, jumping on board with this tech can give you a serious edge over competitors, especially since it works with all sorts of containers — from vials to ampoules — giving you more options for your products.

Some tips:

- Take a close look at your current packaging processes and see where BFS could make things smoother.

- It’s often a good idea to test out BFS with smaller batches first — that way, you can see how it fits into your production before going all-in.

- Keep an eye on industry trends and new developments in BFS tech — staying updated will help your business stay ahead of the game.

FAQS

: Key trends include the increasing demand for sustainable packaging solutions and the rise of automation and smart manufacturing technologies.

The global market for sustainable packaging is expected to reach $1 trillion by 2027, prompting BFS manufacturers to innovate with eco-friendly materials and processes.

Automation allows BFS manufacturers to enhance production efficiency and maintain high-quality standards, with the installation of industrial robots expected to grow by 15% annually.

Businesses should assess the manufacturer’s expertise, production capabilities, equipment, and quality assurance processes to ensure they meet safety and quality standards.

Modern machinery provides precision and flexibility, enabling manufacturers to accommodate various packaging needs and product specifications.

The BFS market was valued at approximately $4.2 billion in 2022 and is expected to grow at a CAGR of 7.5% through 2029.

Leading manufacturers, such as Rommelag, offer innovative technologies like reduced cycle times, which enhance output while maintaining sterility.

Companies that leverage automation in BFS processes can achieve a reduction in operational costs by up to 25%.

A robust quality control system ensures consistent product integrity, reducing the risk of contamination or packaging defects.

By incorporating biodegradable materials into their BFS production line, businesses can appeal to eco-conscious customers.

Conclusion

In today’s super competitive environment, really getting a handle on the ins and outs of Blow Fill Seal manufacturing is pretty much essential if your business wants efficient packaging solutions. The whole process has a bunch of perks—think better product safety and lower chances of contamination. As 2023 rolls on, some major trends are shaping how companies in this space operate, making folks rethink who they’re teaming up with for manufacturing. When you’re picking a partner, it’s super important to look at things like the technology they use, certifications, and quality standards—that’s how you make sure everything runs smoothly and the end product meets expectations.

If you do a quick comparison of the top Blow Fill Seal manufacturers out there, it really shows why investing in the latest tech pays off in the long run—saving you money and boosting efficiency down the line. For example, companies like Shanghai IVEN Pharmatech Engineering Co., Ltd., which has specialized factories dedicated to pharmaceutical and packaging machinery, really showcase what modern manufacturers are capable of. Finding the right partner isn’t just about getting the job done—it’s about making sure your packaging is top-notch and fully compliant with the strict quality rules that are the norm these days. A good match here can make a huge difference for your business's success in today’s market, hands down.

Related Posts

-

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

-

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Finding Top Quality Suppliers for the Best Leak Testing Machines

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

Blog Tags: