How Vial Filling Machines Revolutionize the Pharmaceutical Industry: A Closer Look

Table of Contents

- Understanding the Role of Vial Filling Machines in Pharma Production

- Key Advantages of Automated Vial Filling Processes

- Types of Vial Filling Machines and Their Applications

- Impact of Vial Filling Technology on Drug Safety and Precision

- Future Trends in Vial Filling Machinery and Industry Innovations

- Optimizing Efficiency and Quality: The Comprehensive Guide to Vial Liquid Filling Production Lines

- FAQS

- Conclusion

- Related Posts

In today’s fast-moving pharma world, Vial Filling Machines have really changed the game when it comes to making production more efficient and accurate. If you’ve been following industry trends, you’ll see that the global market for these systems is projected to hit over $5 billion by 2025 — all because there's a rising demand for injectable medicines and biologics. Shanghai IVEN Pharmatech Engineering Co., Ltd. is right at the forefront of this wave. They operate four specialized factories that develop top-notch pharmaceutical machinery, helping streamline the vial filling process. These machines aren’t just about speed; they’re built to meet strict quality standards, boost throughput, and cut down contamination risks. By using cutting-edge tech, they’re helping to keep supply chains running smoothly in a sector where precision and dependability are everything. As the pharma industry keeps evolving, it’s pretty clear that Vial Filling Machines are playing a crucial role in ensuring drugs are delivered safely and effectively — it’s hard to overstate their importance.

Understanding the Role of Vial Filling Machines in Pharma Production

Vial filling machines really are a big deal in the world of pharma production. They play a huge role in making things more efficient and accurate. I read in a report by Grand View Research that the global market for these machines is expected to hit about 1.6 billion dollars by 2025 — that just goes to show how much they're essential for ensuring medicines are properly dosed. With people demanding sterile, high-quality drugs more than ever, companies are investing in more advanced filling tech. Not only does this help them stay compliant with the rules, but it also speeds up how fast they can produce medications.

What’s really cool about vial filling machines is how they take care of boring, repetitive tasks like dispensing liquids, which really cuts down on human errors and contamination. According to MarketsandMarkets, demand for automation in vial filling is expected to grow by about 7.5% annually from 2020 to 2025. That’s a clear sign that the industry is moving toward smarter, faster solutions. This shift doesn’t just speed things up — it helps pharma companies respond quicker to market needs and keeps the supply chain strong. Overall, with safety and efficiency in mind, these machines are leading the charge in changing up how medicines are made nowadays.

Key Advantages of Automated Vial Filling Processes

Automated vial filling has really transformed the pharmaceutical industry in a big way. It’s like, they’ve finally found a way to make things more efficient and precise — which was pretty much impossible before. One of the biggest perks? It cut down on human errors quite a lot. Thanks to these automated systems, the chances of contamination or wrong doses are way lower, so patients can trust that their meds are safe and accurately dosed. And honestly, that kind of accuracy not only ups the quality of the products but also gives consumers a little more confidence in what they’re getting.

Plus, another huge win with these machines is how much faster they can fill vials. As demand for medicines keeps climbing, manufacturers gotta keep up, right? Automated systems can fill vials at lightning speed, which means more products made in less time. That kind of efficiency lets companies react quickly to market shifts or new customer needs, making their whole process more flexible and giving them a solid edge over competitors. It’s pretty impressive when you think about how much things have improved.

Types of Vial Filling Machines and Their Applications

Vial filling machines really are a crucial part of the pharmaceutical world. They help make the whole process of filling vials with just the right amount of medication much smoother and more accurate. There are actually a bunch of different types out there, each suited for specific tasks. For example, volumetric filling machines are great if you're running large quantities of liquid medicines quickly, while aseptic filling machines are key when you need to keep things sterile—especially for sensitive biologics or injectables.

At Shanghai IVEN Pharmatech Engineering Co., Ltd., we take pride in our expertise when it comes to pharmaceutical machinery. We're all about innovation and quality. We have four professional factories making a wide range of equipment, including vial filling machines, so our clients get access to cutting-edge technology that meets all the industry standards. Our machines don’t just cut down on labor costs—they also help streamline the entire production process. It’s all part of our mission to support the pharma industry in meeting the rising global demand for safe and efficient medication delivery systems.

How Vial Filling Machines Revolutionize the Pharmaceutical Industry: A Closer Look

| Type of Vial Filling Machine | Applications | Filling Method | Production Rate |

|---|---|---|---|

| Semi-Automatic Vial Filling Machine | Small to medium-scale production | Piston or syringe | 300-600 vials per hour |

| Automatic Vial Filling Machine | High-volume production | Gravity or vacuum | 1200-3000 vials per hour |

| Aseptic Vial Filling Machine | Sterile products, vaccines | Controlled environment | 600-1000 vials per hour |

| Multi-Dose Vial Filling Machine | Injectable formulations | Peristaltic pump | 500-800 vials per hour |

| Vial Washing and Filling Machine | Complete vial processing | Washing and filling in one | 700-1500 vials per hour |

Impact of Vial Filling Technology on Drug Safety and Precision

Over the years, vial filling tech has really stepped up in making sure drugs are safer and more precisely packaged. These days, modern vial filling machines are pretty advanced — they automate pretty much the whole process, which helps cut down on human mistakes. That’s super important in pharma, where even tiny errors can pose serious health risks. Thanks to fancy sensors and smart controls, each vial gets the right amount of medication, and the whole process is monitored in real-time, so everything stays compliant with tight regulations.

On top of that, tech like robotic systems and AI has completely changed how vials are filled and sealed. These innovations don’t just make operations run smoother; they also boost the accuracy and cut down on contamination risks. Better precision means patients get the correct dosage, which is crucial for safety and effectiveness. As pharma companies keep adopting these new tools, they’re able to deliver more reliable medications, which ultimately helps improve health outcomes for people around the world.

Impact of Vial Filling Technology on Drug Safety and Precision

Future Trends in Vial Filling Machinery and Industry Innovations

You know, the pharmaceutical industry is really going through a big shake-up these days, largely thanks to all the new stuff happening with vial filling machines. Companies are all about boosting efficiency and getting things just right, so they've been rolling out more and more automated systems. These new machines don’t just get the job done faster—they also keep everything super clean and safe, which is a huge deal. They're pretty versatile too, handling different vial sizes and types, so manufacturers don’t get stuck with one rigid setup. It’s like they’re built to grow and adapt with the industry’s ever-changing needs.

Looking ahead, things are only going to get smarter. We’re talking about integrating features like artificial intelligence and machine learning—tools that can fine-tune the filling process, cut down on mistakes, and make tracking data a lot easier. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd., with their high-tech factories dedicated to pharma machinery, are really leading the charge here. They’re providing reliable solutions that help meet the rising demands for efficiency and strict compliance.

If you're on the hunt for a vial filling machine, my advice is to keep an eye on automation features, make sure it works with different vial types, and don’t forget to consider how easy it is to maintain. Staying in the loop with the latest industry standards and tech trends can seriously make a difference in how smooth your operations are. Plus, teaming up with manufacturers who are on the cutting edge can actually make your life a lot easier and your results much better.

Optimizing Efficiency and Quality: The Comprehensive Guide to Vial Liquid Filling Production Lines

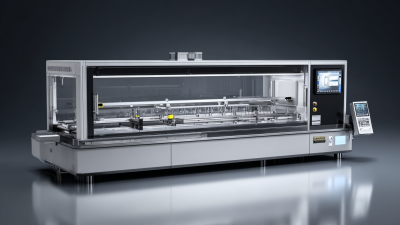

In the realm of pharmaceutical manufacturing, the optimization of efficiency and quality in vial liquid filling production lines is critical. This comprehensive guide delves into the key components that contribute to an effective production process. The vial liquid filling line incorporates several advanced machines designed to streamline operations and ensure product integrity. Among these are the vertical ultrasonic washing machine, the RSM sterilizing drying machine, and the filling and stoppering machine, complemented by the KFG/FG capping machine.

Each piece of equipment serves a specific function, enhancing the overall efficacy of the production line. The ultrasonic washing machine employs sonic waves to thoroughly cleanse vials, ensuring that all contaminants are eradicated before the filling process begins. Following this, the RSM sterilizing drying machine utilizes advanced techniques to sterilize and dry the vials, preparing them for safe and hygienic liquid filling. The filling and stoppering machine then accurately dispenses the liquid while sealing the vials securely, ensuring that their contents are preserved. Finally, the capping machine effectively seals the vials, providing an additional layer of security against contamination.

Notably, these machines can operate cohesively as part of an integrated system or function independently, offering flexibility to manufacturers based on their production needs. By optimizing these production line components, manufacturers can enhance operational efficiency while maintaining the highest quality standards for their products.

FAQS

: Vial filling machines are crucial for ensuring efficiency and accuracy in pharmaceutical production, significantly impacting the precise dosage of medications. The global vial filling machinery market is projected to reach USD 1.6 billion by 2025, underlining their growing importance.

Automated vial filling machines minimize human error by automating tasks such as dispensing liquids, thereby reducing contamination risks and ensuring accurate dosing of pharmaceuticals.

Automated vial filling processes enhance efficiency and precision, significantly increasing production speed while reducing the risk of contamination and incorrect dosing, which in turn boosts product quality and consumer confidence.

The demand for automated vial filling systems is expected to grow at a CAGR of 7.5% from 2020 to 2025, reflecting the pharmaceutical industry’s shift toward automation for improved production timelines and adaptability to market demands.

Future trends include the integration of smart technologies such as artificial intelligence and machine learning, which optimize filling processes and enhance data tracking, as well as improved scalability for handling diverse vial sizes and materials.

Manufacturers should consider automation capabilities, compatibility with various vial types, and the machine's maintenance requirements to ensure compliance with industry standards and improve production quality.

Advanced filling technologies allow pharmaceutical companies to adapt quickly to changing market demands and accelerate production timelines, thereby enhancing the robustness of the supply chain.

Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are at the forefront of innovations in vial filling machinery, providing reliable solutions that meet the growing demands for efficiency and compliance in the pharmaceutical sector.

Conclusion

Vial filling machines are really essential in the pharmaceutical world. They help make the production process smoother and boost efficiency all around. These automated systems bring so many benefits—like improving accuracy, cutting down on contamination risks, and speeding up turnaround times. There are different types of vial filling machines out there, each suited for specific needs, so pharma companies can handle a variety of production demands while still keeping safety and precision front and center.

As technology keeps advancing, the way vial filling machines are improving continues to shape how drugs are made and how safe they are. New innovations in machinery are setting the stage for future trends, showing just how committed the industry is to quality and efficiency. At Shanghai IVEN Pharmatech Engineering Co., Ltd., we’re proud to be leading the way in making cutting-edge vial filling machines and other key pharmaceutical equipment. Our goal? Supporting the industry’s growth and helping it keep reaching for excellence.

Related Posts

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

-

Innovations in Vial Filler Machines at the 138th China Import and Export Fair 2025

-

Revolutionizing Pharmaceutical Production with Advanced Vial And Ampoule Filling Machine Technology

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

-

7 Compelling Reasons to Choose the Best Clean Steam Generator Manufacturers for Your Business Needs

-

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

Blog Tags: