High reputation Clean Room Floor - Syringe Production Line – IVEN

High reputation Clean Room Floor - Syringe Production Line – IVEN Detail:

The whole production process of Syringes is consist of 6 main steps:

1. Injection Molding Machine

2. Scale Line Printing Machine

3. Assembling Machine

4. Individual Syringe Packaging Machine: PE bag package/blister package

5. Secondary packaging & CARTONNING

6. EO sterilizer

Product Video

Working Process:

1. Barrel Injection Molding

4. Individual Syringe Packaging:

2. Barrel scale line printing

5. Secondary packaging & CARTONNING

3. Assembling

6. EO Sterilization

Our Advantages:

There are 4S main advantages to share with you about our machines.

1.Safety. Our machines are equipped with protective cover, when the machine is running, the cover is closed, when the cover is open, the machine will stop running, which prevent worker from injury and also there will be no dust pollution to pollute syringe in process.

2.Stable running. If you only plan to run the machine 8 hours at the beginning, but you get more and more orders, so you plan to run it 16 or 24 hours per day. How can you do it without a good machine? For our machines, you totally no need to worry about it. Our machine can keep stable running 24 hours per day. So you can make the production shifts according to your demand. If later even you run it 24 hours still not enough for your demand, cause you get more and more orders, welcome to come to us for the second line or the third line.

3.Save labors. Save labor cost. It is fully automatic controlled by PLC. The machines are connected together. Not separate ones. It can do printing, assembling in one connected line. No need labors to do the transfer when printing is finished. Finished printing product will be transfereed to assemabling machine automaticlly.

4.Save materials. Our machines have high qualified rate. It is more than 99.9%. There will be almost no waste for you. More qualified product, more profit.

Case show:

Injection Molding Machine

Syringe Scale Line Printing Machine & Assembling Machine

Packing Line

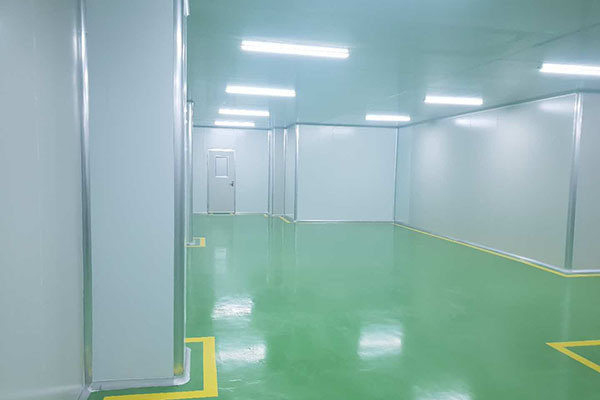

Clean Room System

Product detail pictures:

Related Product Guide:

Our company promises all buyers of the first-class products and solutions as well as most satisfying post-sale support. We warmly welcome our regular and new shoppers to join us for High reputation Clean Room Floor - Syringe Production Line – IVEN , The product will supply to all over the world, such as: Roman, Mombasa, Los Angeles, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. Best efforts are going to be produced to supply you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share the top trading practical experience with all our merchants.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.