Intravenous Therapy Production Line - China Factory, Suppliers, Manufacturers

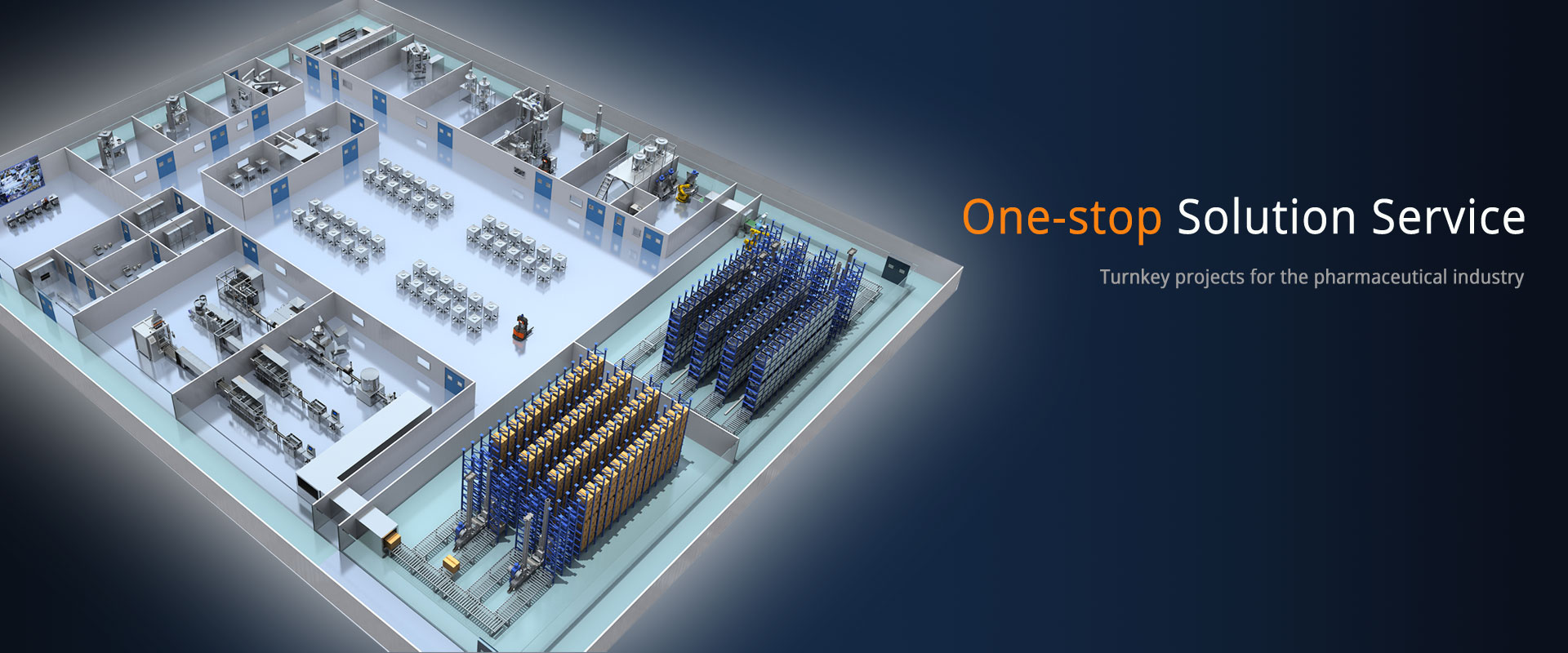

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Intravenous Therapy Production Line, Non-Pvc Soft Bag Machinery, Sugar Syrup Dispenser Machine Price, Ampoule Washing Machine Qualification,Vial Cap Sealing Machine. We are confident to make great achievements in the future. We are looking forward to becoming one of your most reliable suppliers. The product will supply to all over the world, such as Europe, America, Australia,Malta, Bulgaria,Tunisia, Tunisia.It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We provide wholesale prices on all our quality parts so you are guaranteed greater savings.

Related Products