You can make packaging faster with the IVEN Syrup Filling and Capping Machine. It is important to be exact and dependable at every step. This includes filling and capping. Automatic controls stop problems like spills or missing bottles. Special features work together. They help you get the same results every time.

Packaging Challenges in Pharmaceuticals

Common Issues in Syrup Packaging

There are many problems with syrup packaging. Bottles might leak if they are not sealed well. Syrup can spill and make things sticky. Sometimes, bottles do not have the same amount of syrup. Caps might not be tight enough. These problems can waste syrup and cause you to lose products. You want every bottle to look the same and follow safety rules.

Here are some problems you might see:

●Bottles with the wrong amount of syrup

●Caps that are loose or not straight

●Syrup spills when filling bottles

●Bottles that break when putting on caps

●Packaging that takes too long

Impact on Production Efficiency

Problems with packaging can slow down your work. If you stop to clean up spills or change broken bottles, you lose time. You might have to check each bottle by hand, which takes longer. When you fill bottles by hand, you can make mistakes and get different results. These mistakes can make your work slower and cost more money.

You want to make your packaging better. Machines that fill bottles right and put caps on tight help you work faster. You do not have to fix as many mistakes. You also get better results with every bottle. This helps you trust your packaging and keep your products safe.

IVEN Syrup Filling and Capping Machine Features

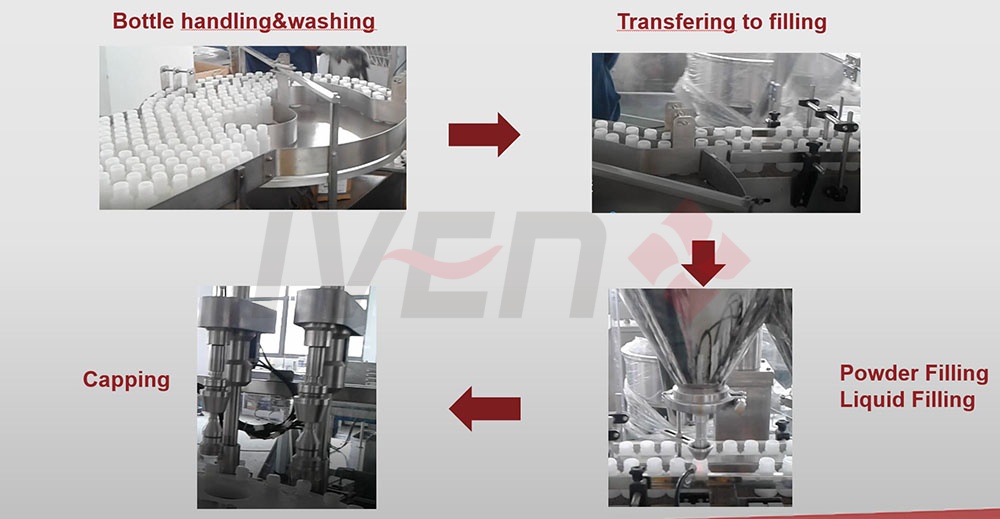

The IVEN Syrup Filling and Capping Machine does many jobs. It washes, dries, sterilizes, fills, and caps bottles. All these steps happen in one machine. This saves you time and helps you work faster. You do not need a different machine for each job. You can trust this machine to do every step.

Ultrasonic Washing and Sterilizing

You need bottles to be clean for syrup. The machine uses ultrasonic washing to get rid of dirt and dust. It cleans inside and outside the bottles. After washing, bottles go through sterilizing. This kills germs and keeps your syrup safe. You do not have to worry about germs. The automatic system gets every bottle ready for filling.

Precision Filling System

You want every bottle to have the right amount of syrup. The machine uses a precision filling system. It has a special control program to set the amount. There are 16 filling heads that work fast and fill bottles correctly. The liquid filling is very close to perfect. The machine stops filling if there is no bottle. This saves syrup and stops waste.

Here is how the filling works: Bottles move to the filling spot. The system checks for bottles. The filling heads add syrup with high accuracy. The machine makes sure bottles are in the right place.

You do not have to worry about spills or wrong amounts. The automatic filling machines keep things running well. You get the same results every time.

Automatic Capping Machines

After filling, bottles need to be sealed. The machine uses automatic capping machines to put caps on tight. There are 12 capping heads. The capping rate is over 99.8%. Rolling knives and heads fit many bottle shapes. The system checks for caps and bottles. If there is no cap, the machine stops capping. This keeps bottles safe from damage.

You do not have to worry about loose caps or broken bottles. The automatic capping machines work quickly and keep packaging safe. You can change the speed to match your needs.

The IVEN Syrup Filling and Capping Machine fixes many packaging problems. You get clean bottles, correct filling, and tight caps. The automatic features help you make fewer errors and save time. You can trust this machine to make your work better and help you reach your goals.

Benefits for Manufacturers

Increased Speed and Throughput

You want your packaging line to go fast. The IVEN Syrup Filling and Capping Machine helps you do this. It uses 16 filling heads and 12 capping heads. This means you can fill many bottles at the same time. The automatic system keeps everything moving. You do not have to stop for manual checks. You finish more bottles in less time. Your packaging line works better. You see your work get faster every day.

Enhanced Accuracy and Quality

You need each bottle to have the right amount of syrup. The machine makes sure every bottle is filled correctly. The control program checks every step. You get the same results for each bottle. The machine stops filling if there is no bottle. This helps stop mistakes. The capping system works very well, with a rate over 99.8%. You can trust your packaging is good. Your products look nice and follow safety rules.

Reduced Waste and Damage

You want to save syrup and bottles. The machine helps you waste less in many ways. The no bottle no filling feature stops syrup from spilling. The automatic capping system keeps bottles from breaking. You see less waste and fewer broken bottles. The damage rate is less than 0.1%. You do not have to throw away as many bottles or syrup. This saves you money and helps the environment. Machines like this help you use your resources better and waste less.

You get many good things from using the IVEN Syrup Filling and Capping Machine. You see faster packaging, better filling, and safer capping. The automatic features help you work smarter. Your packaging line gets stronger and more reliable.

You can see how the IVEN Syrup Filling and Capping Machine helps with packaging problems. It gives you clean bottles every time. The filling is always correct. The caps are tight on each bottle. The machine uses smart controls to work fast. You do not waste as much syrup or time. You can trust the results from this machine. It helps you follow safety rules.

Post time: Dec-24-2025