Non-Pvc Soft Bag Manufacturer - China Manufacturers, Suppliers, Factory

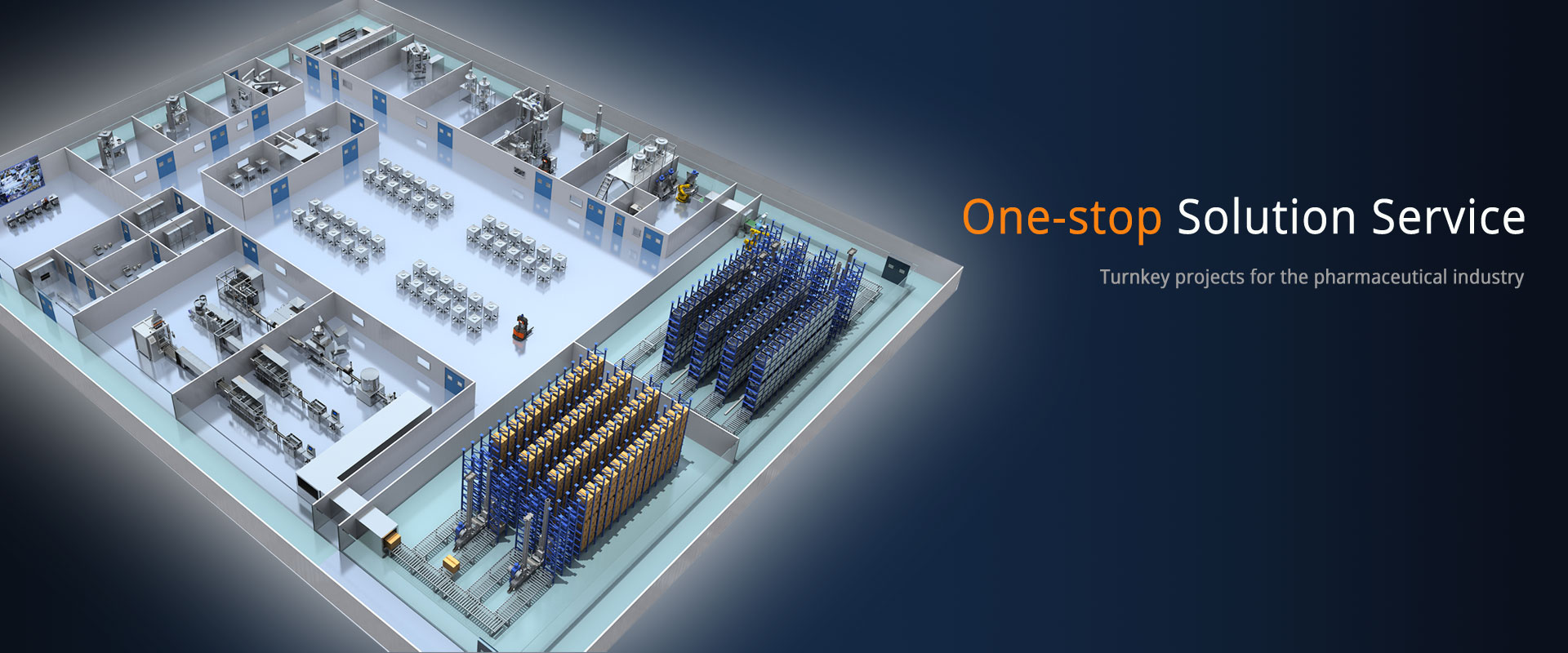

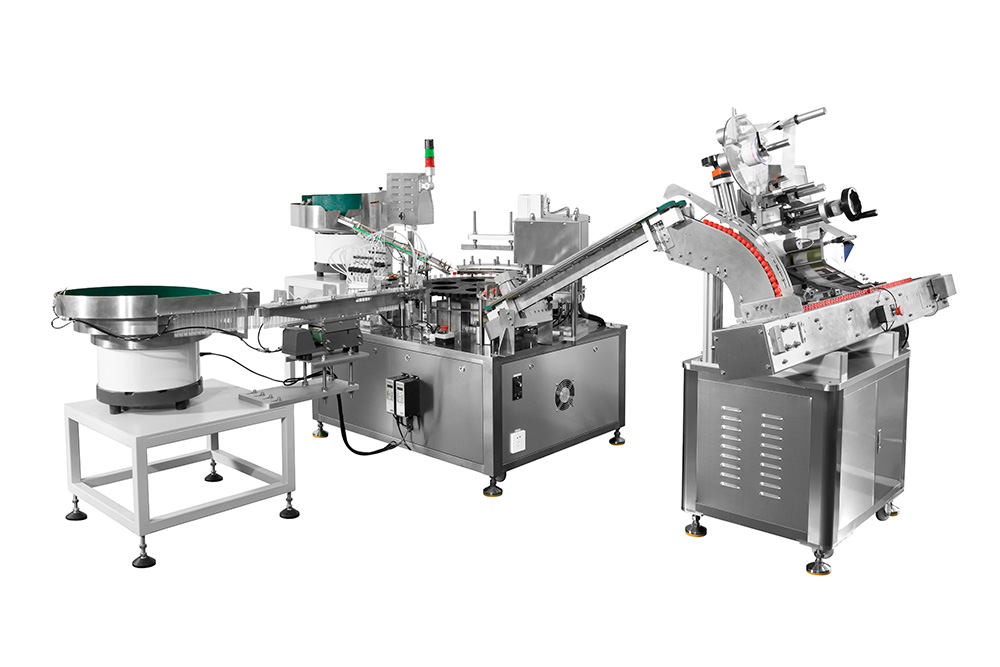

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for Non-Pvc Soft Bag Manufacturer, Ampoule Washing Filling Sealing, Vial Crusher Machine, Plastic Ampoule Filling Machine,Vial Crimping Machine. For anyone who is intrigued in almost any of our solutions or want to talk about a custom made purchase, make sure you sense free of charge to get in touch with us. The product will supply to all over the world, such as Europe, America, Australia,Slovakia, Paraguay,Malawi, Bulgaria.To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.

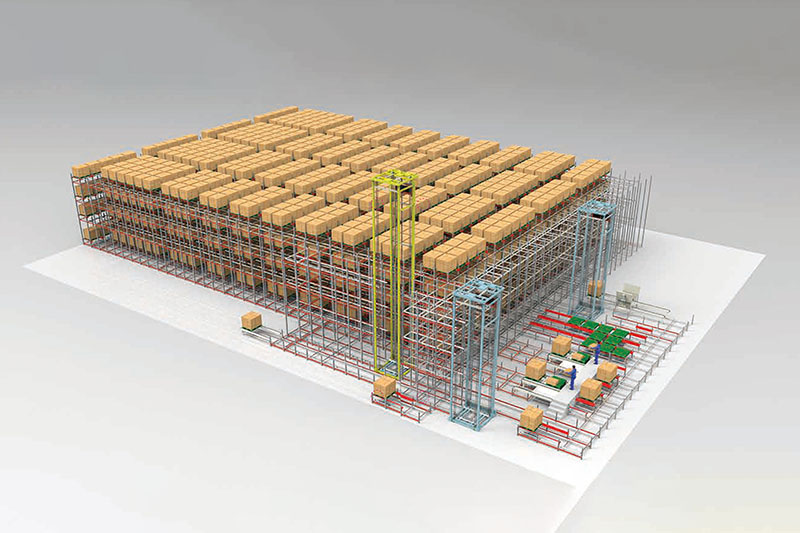

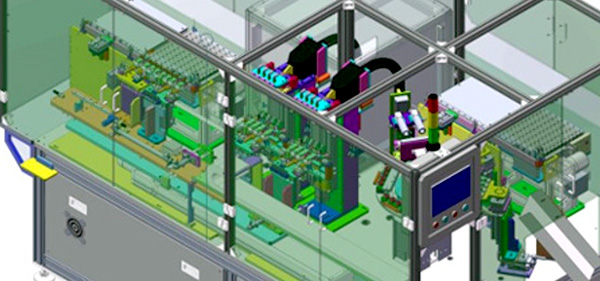

Related Products