Smart Intensive Warehousing System - Manufacturers, Factory, Suppliers from China

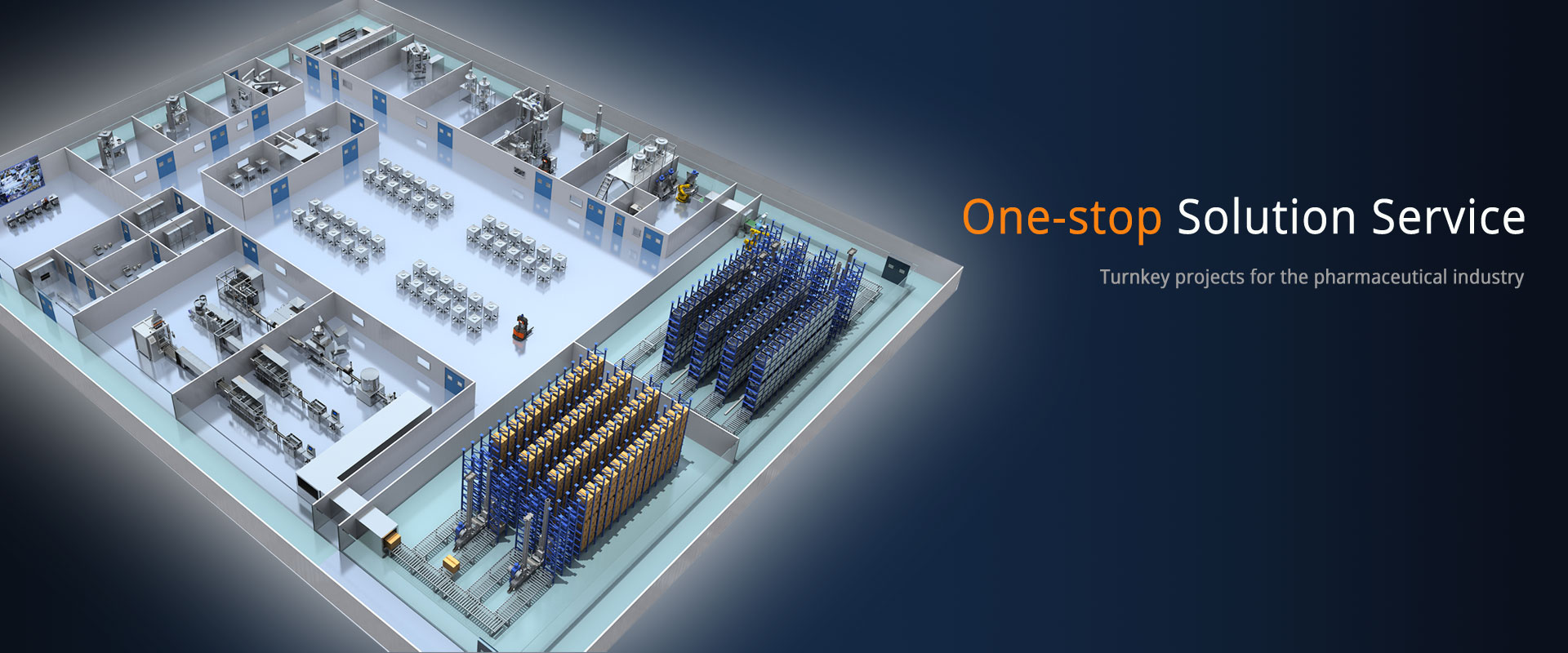

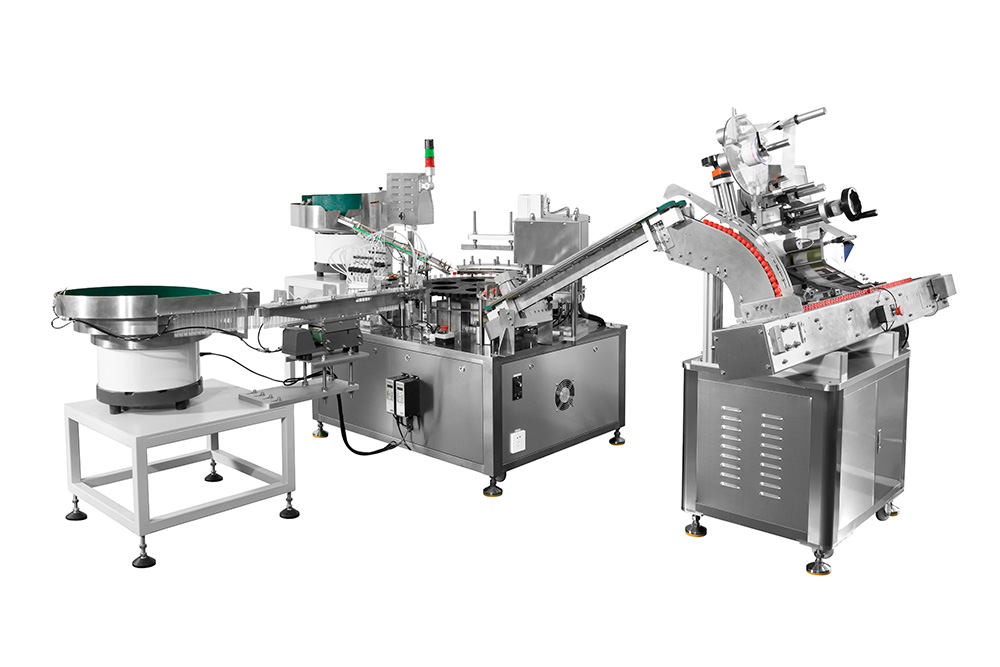

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Smart Intensive Warehousing System, Ampoule Machine Coudre Singer, Ampoule Machine Bernina, Ampoule Filling And Sealing Machine Laboratory,Vial Machine Meaning. We are sincerely looking forward to cooperate with buyers all around the world. We imagine we will satisfy you. We also warmly welcome shoppers to visit our organization and purchase our merchandise. The product will supply to all over the world, such as Europe, America, Australia,Norway, Israel,Benin, London.we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

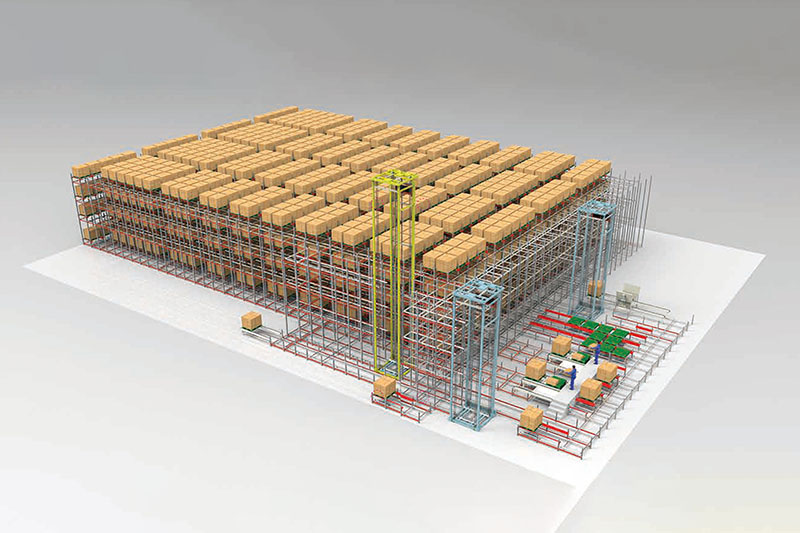

Related Products