Vial Filler Machine - China Manufacturers, Suppliers, Factory

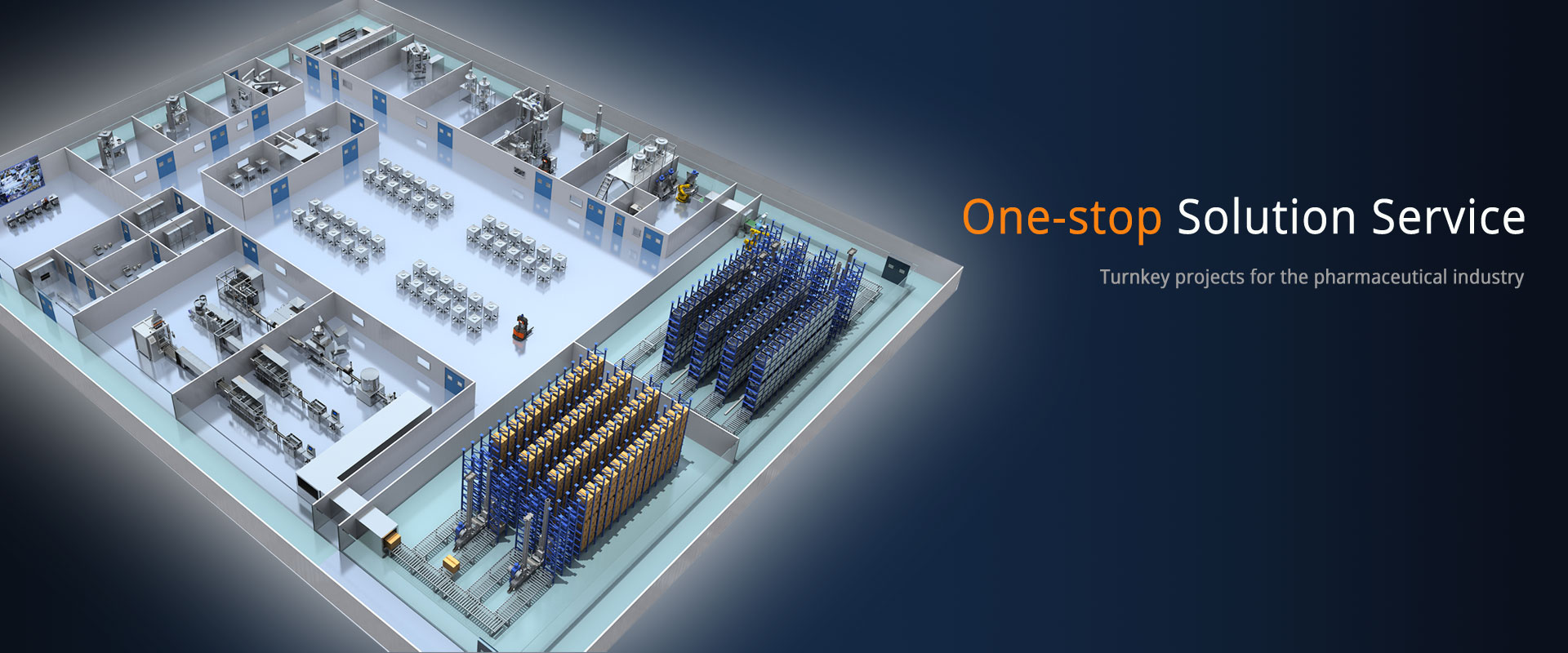

We insist on offering premium quality creation with very good company concept, honest product sales along with the finest and fast assistance. it will bring you not only the premium quality item and huge profit, but the most significant is to occupy the endless market for Vial Filler Machine, Ampoule Labelling Machine, Tofflon Ampoule Inspection Machine, Pre Filled Syringe Filling Machine,Ampoule Filling Machine Manufacturers In Ahmedabad. We invites you and your company to thrive together with us and share a dazzling foreseeable future in world-wide market place. The product will supply to all over the world, such as Europe, America, Australia,Swiss, Bhutan,belarus, Grenada.We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

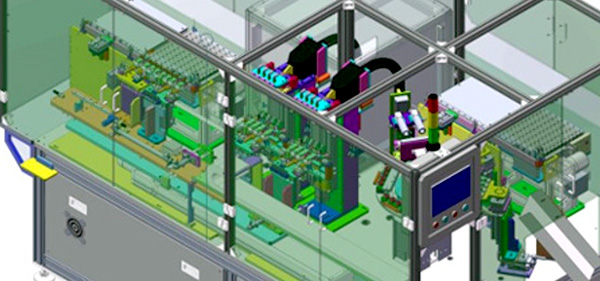

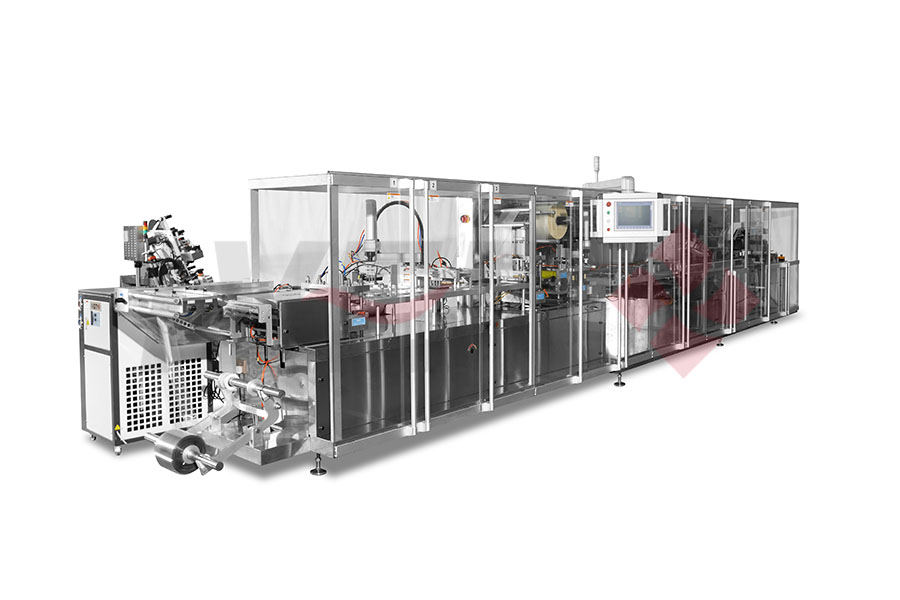

Related Products