Factory selling Ampoule Labelling Machine - Cartridge Filling Production Line – IVEN

Factory selling Ampoule Labelling Machine - Cartridge Filling Production Line – IVEN Detail:

Brief introduction

IVEN cartridge filling production line (carpule filling production line) welcomed a lot for our customers to produce cartridges/carpules with bottom stoppering, filling, liquid vacuuming (surplus liquid), cap adding, capping after drying and sterilizing. Full safety detection and intelligent control to guarantee stable production, like no cartridge/carpule, no stoppering, no filling, auto material feeding when it is running out.

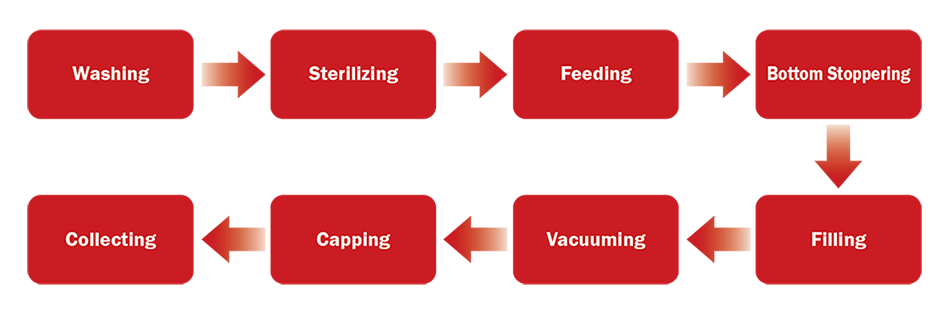

Working Process

Cartridges/Carpules feeding wheel after sterilization —- Bottom part stoppered — Conveyed to filling station — Filled the 2nd time to full and vacuuming the redundant solution — Conveyed to the capping station — Conveyed to cartridges/carpules collection plate.

Technical Features

1. Adopt the world’s latest technology, strictly make in accordance with GMP standard with compact structure.

2. Finish stoppering, filling, capping automatically.

3. All parts contact with medical solution adopt 316L S/S or the material which has no chemical change with drugs.

4. Servo motor operating parameters can be set freely according to filling volume and running speed, efficiently enhance filling precision.

5. Easy to change the specification part.

6. No cartridge/carpule no stoppering; no cartridge/carpule no filling; no cartridge/carpule no capping.

7. Auto detection function for stopper and aluminium cap.

8. Auto shutdown protection when open the door.

9. The reset button is available.

Configuration

|

No |

Item |

Brand & Material |

|

1. |

Servo motor |

|

|

2. |

Touch Screen |

|

|

3. |

Ball screw |

ABBA |

|

4. |

Breaker |

|

|

5. |

Relay |

|

|

6. |

Filling pump |

Ceramic pump |

|

7. |

Mingwei |

|

|

8. |

Solution contact part |

316L |

Technical Parameters

|

No |

Item |

Description |

|

1. |

Applicable range |

1-3 ml cartridge |

|

2. |

Production capacity |

80-100 cartridges/min |

|

3. |

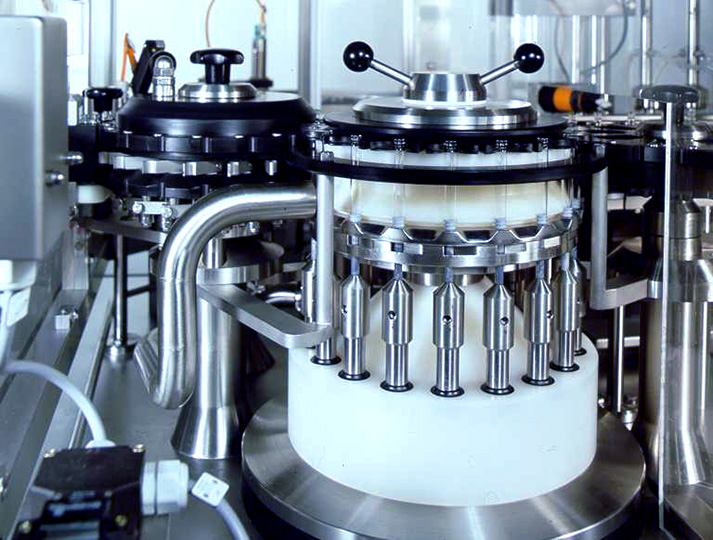

Filling heads |

4 |

|

4. |

Vacuum consumption |

15m³/h, 0.25Mpa |

|

5. |

Stoppering heads |

4 |

|

6. |

Capping heads |

4 |

|

7. |

Power |

4.4kw 380V 50Hz/60Hz |

|

8. |

Filling accuracy |

≤ ± 1% |

|

9. |

Dimension( L*W*H) |

3430×1320×1700mm |

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Factory selling Ampoule Labelling Machine - Cartridge Filling Production Line – IVEN , The product will supply to all over the world, such as: Swansea, Mauritania, Maldives, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!