Herb Extraction Production Line (Artemisinin extraction, CBD extraction)

Herb Extraction Production Line Introduction:

Natural flavors and fragrances: tobacco leaves, edible essence, daily chemical essence, flavor essence.

Plant extraction: Traditional Chinese herbal medicine production line, raw material medicine to deepen the processing. Bones: extraction of bone, bone collagen, edible flavor.

Biological fermentation: genetic engineering, cell engineering, fermentation engineering, enzyme engineering.

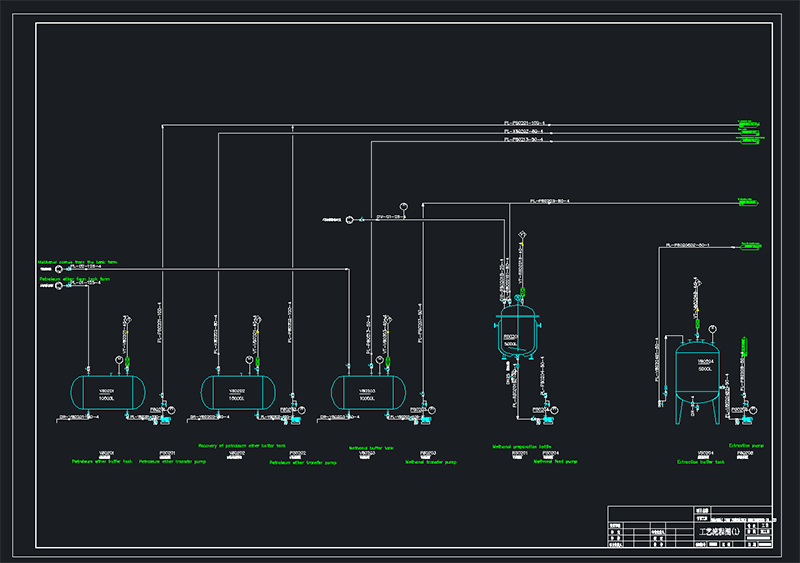

Production Procedures:

1. To the initial processing of raw materials, through cutting, crushing, screening and other means, to carry out the weight of the pre cast, the sub package;

2. According to the different process, choose different pressure extraction method (the extraction of the material from the way the material is different), through multiple extraction to obtain the required ingredients;

3. Material slag by hanging cage or rotary dumping way, collecting spare;

4. After the extraction of the initial filter, through the heating cooling, centrifugal repeated treatment, get the extract liquid;

5. Extract by low temperature concentration, liquid separation, liquid solvent separation, high density, high concentration of concentrate;

6. Concentrate through the deployment of the reaction, the pipeline shear, the deployment of sterilization, access to intermediates;

7. Intermediate by filling, sterilization, access to liquid products; or by drying, grinding, etc.

8. Key equipment to use advanced technology, fast, strong adaptability, high quality products;

9. The whole process system is closed, steam, hot water, organic solvent recycling, energy saving, high efficiency, green, environmental protection in line with the international development;

On the basis of the traditional process flow, it can realize the process automation control of the whole process, configure all the detection point instruments required by the process (temperature, pressure, liquid level, flow rate, automatic control valve, etc.), design the corresponding process flow automation control sequence and CIP online automatic cleaning program, select high-end automatic control software, improve the stability of the system, and can take into account the DCS central control room;

The EMS information control system is added on the basis of workshop automation, and the workshop data, material management data, material approval process, release management, workshop video monitoring, process management and other related content are integrated and centralized, so that the management can share workshop information anytime and anywhere.

Automated workshop instrument valve selection, using advanced wireless instruments to establish a workshop wireless transmission network, different from the traditional cable tray wiring, so that the workshop layout looks simple and beautiful.