High Performance Syringe Mould Manufacturers - Hemodialysis Solution Production Line – IVEN

High Performance Syringe Mould Manufacturers - Hemodialysis Solution Production Line – IVEN Detail:

Hemodialysis Solution Production Line Introduction:

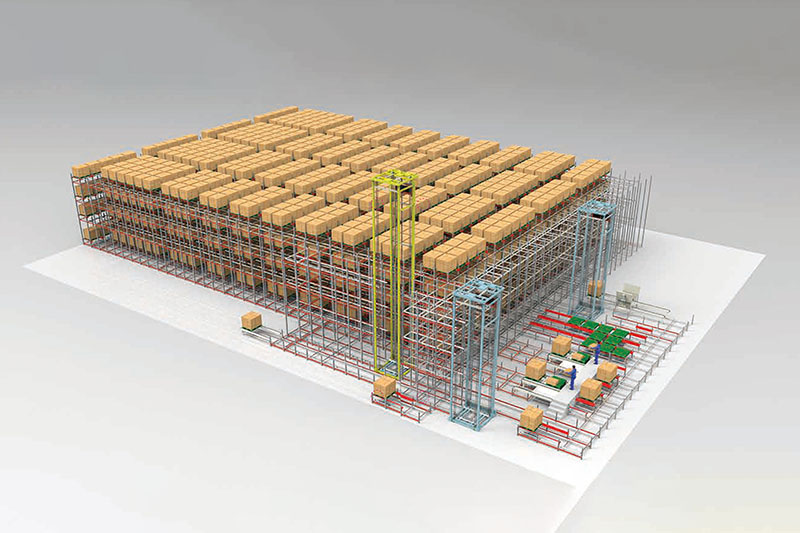

The Hemodialysis filling line adopts advanced German technology and is specially designed for dialysate filling. The part of this machine can be filled with a peristaltic pump or a 316L stainless steel syringe pump. It is controlled by PLC, with high filling accuracy and convenient adjustment of the filling range. This machine has reasonable design, stable and reliable operation, easy operation and maintenance, and fully meets GMP requirements.

Application

For Hemodialysis barrel washing filling capping.

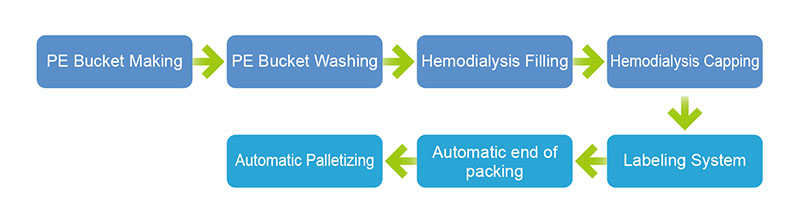

Hemodialysis Solution Production Line Procedures

Hemodialysis filling line

- High precision: adopt weigh filling system (METTLER TOLEDO weighing sensor), increase the filling precision. Special small ball conveying, make the bottle running stably on conveyor.

- Fast-slow filling valve, guarantee fast filling in earlier stage to save filling time, and slow filling in last stage to increase the filling precision. Motor top-bottom filling, reduce the foaming while filling.

- Mounted collect tray under filling nozzle in case of drip from the nozzle. Our nozzle has the function shut on/off to seal the nozzle mouth, guarantee no dripping touch to the bottle outside.

- Whole machine is controlled intelligently, bottle sensor reading, no bottle no filling, crash proof design for each container.

- Electric components adopt French Schneider, like PLC, HMI, inverter and breaker. integrate pneumatic controlling, more stable, safety, green and low consumption.

- Machine is fully covered by SS304, tempered glass door, better adaptability of various kinds of environment, anti-corrosive, and easy clean.

- Pipeline support CIP/SIP

Product detail pictures:

Related Product Guide:

With our great management, potent technical capability and strict excellent handle procedure, we continue on to provide our customers with reputable top quality, reasonable selling prices and great providers. We purpose at becoming amongst your most trusted partners and earning your satisfaction for High Performance Syringe Mould Manufacturers - Hemodialysis Solution Production Line – IVEN , The product will supply to all over the world, such as: Dominica, Venezuela, Haiti, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve products and provide more comprehensive services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

Send your message to us:

Write your message here and send it to us