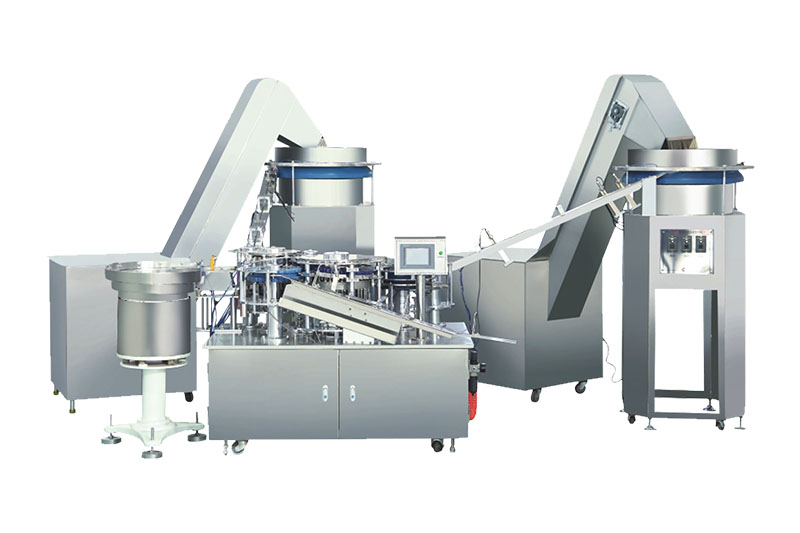

Vial Sealing Machine Validation - Factory, Suppliers, Manufacturers from China

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Vial Sealing Machine Validation, Ampoule Making Machine, Vial Filling Machine Manufacturers, Injectable Vial Oem,Pharmaceutical Machines Service. Therefore, we can meet different inquiries from different consumers. You should find our web page to check additional info from our products. The product will supply to all over the world, such as Europe, America, Australia,Boston, Leicester,Jeddah, Lisbon.Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

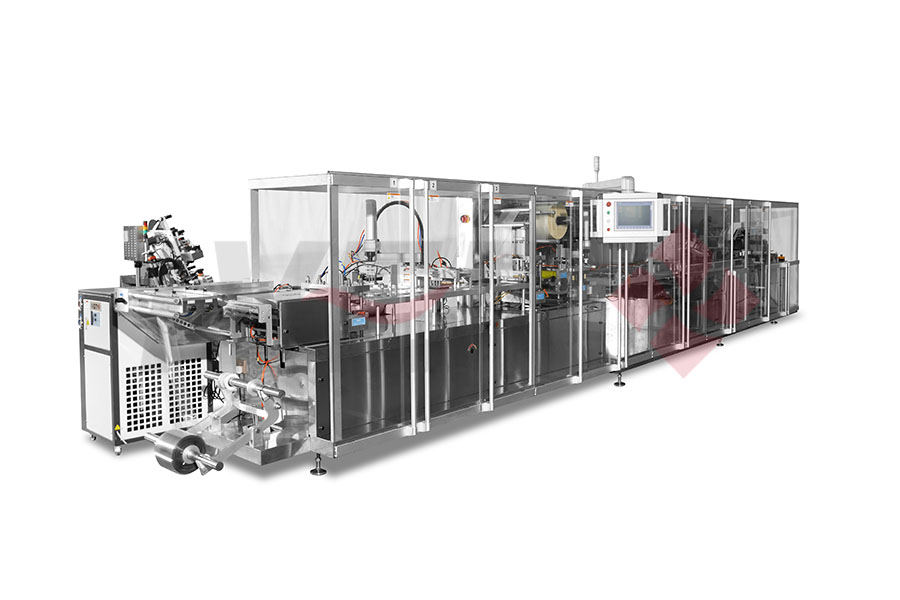

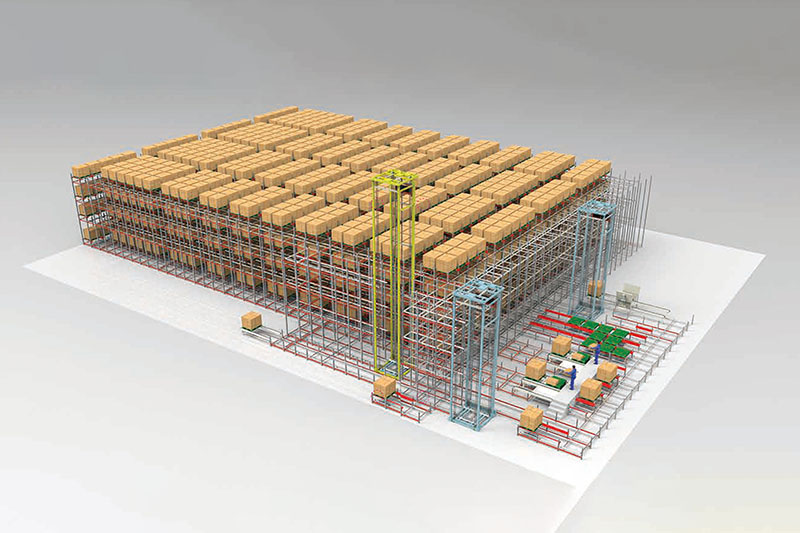

Related Products