factory customized Syringe And Needle Making Machine - Syringe Assembling Machine – IVEN

factory customized Syringe And Needle Making Machine - Syringe Assembling Machine – IVEN Detail:

Brief Introduction:

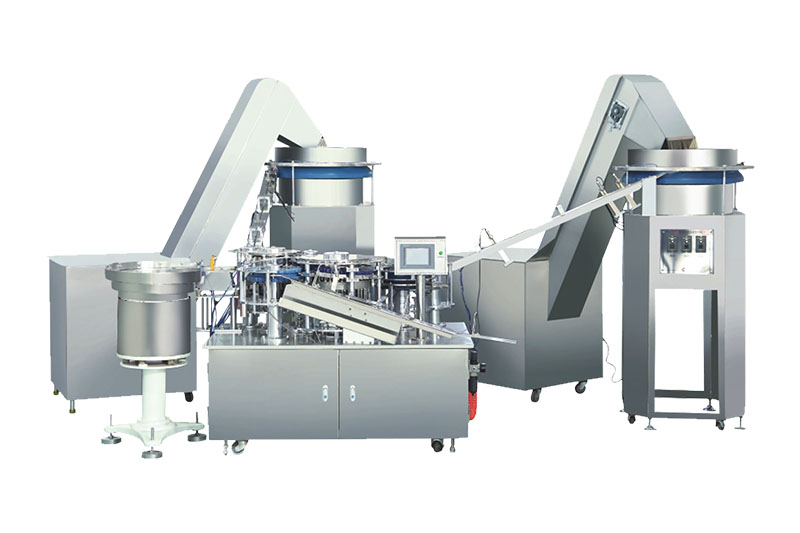

Our Syringe Assembling Machine is used for assembling syringe automatically. It can produce all kinds of syringes, including luer slip type, luer lock type, etc.

Our Syringe Assembling Machine adopts LCD display to display the feeding speed, and can adjust the assembly speed separately, with electronic counting. High efficiency, low power consumption, easy maintenance, stable operation, low noise, suitable for the GMP workshop.

Product Video

Product Description:

Our syringe assembling machine consists of feeding system and assembly mechanism.

Feeding system: feed 4 components of syringe (plunger/stopper/needle/barrel) to the assembly mechanism.

Feeding system are composed of feed bin and centrifugal feeder for barrel/plunger, hopper and feeder for needle/stopper.

Feeding system with photoelectric sensors, when assembling mechanism is full of products it will stop feeding, and when there is lack of products it will start working automatically.

Assembly Mechanism: assemble all parts of components together as a finished product. Usually, It completes 3 actions: action 1 – assemble plunger with rubber stopper; action 2 – assemble barrel with needle; action 3 – assemble plunger with stopper and barrel with needle.

Main Technical Parameters:

|

Model |

ZZ-001IV |

| Applicable Specification | 2ml~50ml |

| Production Capacity | 150-250pcs/min |

| Overall Dimension | 4200*3000*2100mm |

| Weight | 1500kgs |

| Power Supply | AC220V/3KW |

| Compressed Air Flow | 0.3m³/min |

Main Configuration List

|

No. |

Name |

Brand |

Remark |

|

1 |

Frequency converter | Mitsubishi (Japan) | |

|

2 |

Motor | Taizhou, China | |

|

3 |

Reducer | Hangzhou, China | |

|

4 |

Adjustable-speed motor | Mitsubishi (Japan) | |

|

5 |

Control system | Single chip microcomputer | |

|

6 |

Touch Screen | China | |

|

7 |

CCD vision sensor system | KEYENCE (Japan) | |

|

8 |

The housing material | SS 304, Plated metal | |

|

9 |

Dust cover | Aluminum profile |

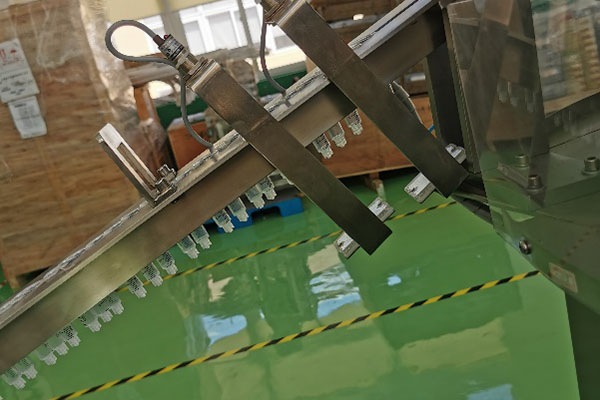

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for factory customized Syringe And Needle Making Machine - Syringe Assembling Machine – IVEN , The product will supply to all over the world, such as: Canada, Holland, Haiti, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.