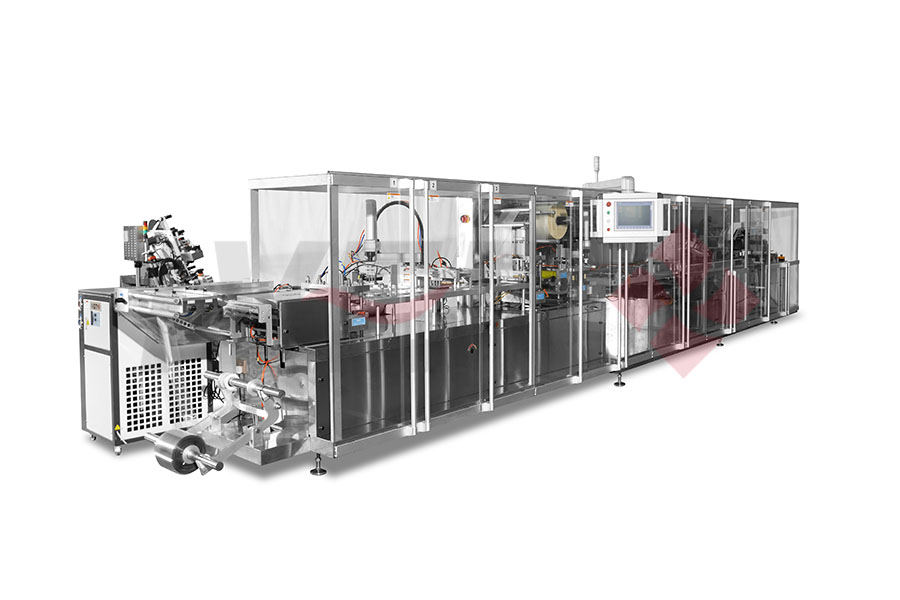

Non-Pvc Soft Bag Oem - Factory, Suppliers, Manufacturers from China

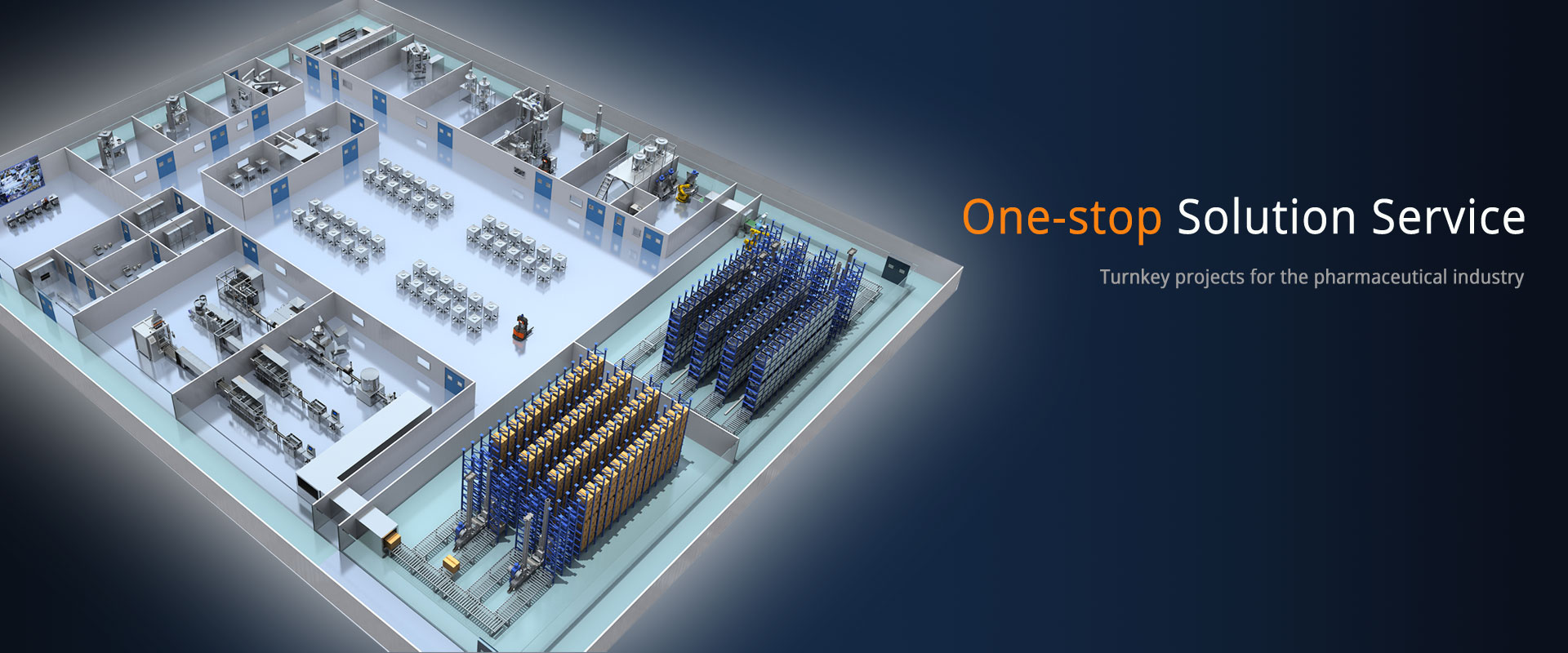

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for Non-Pvc Soft Bag Oem, Glass Bottle Packing Machine, Pharmaceutical Filling Machinery, Pharmaceutical Filling Machine,Injectable Ampoule Machine. Welcome all nice buyers communicate details of solutions and ideas with us!! The product will supply to all over the world, such as Europe, America, Australia,Italy, Durban,Mexico, European.we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

Related Products