Ampoule Leak Testing Machine - China Manufacturers, Factory, Suppliers

As a way to present you with ease and enlarge our enterprise, we also have inspectors in QC Workforce and assure you our greatest support and solution for Ampoule Leak Testing Machine, Vial Washing Machine Working Principle, Ampoule Machine Coudre Singer, Glass Ampoule Filling,Injectable Liquid Production Line - Ampoule Svp. The mission of our firm should be to provide the best high quality goods with finest price tag. We've been on the lookout forward to doing organization with you! The product will supply to all over the world, such as Europe, America, Australia,Swedish, Cape Town,Argentina, Jakarta.Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

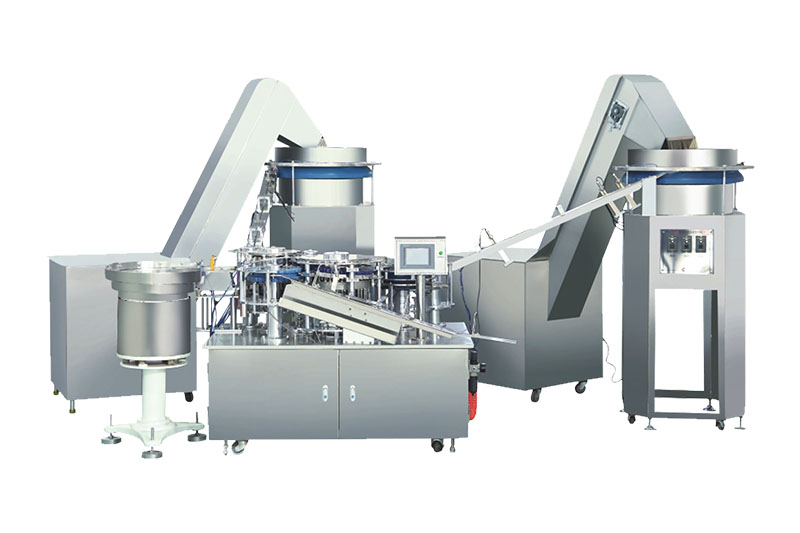

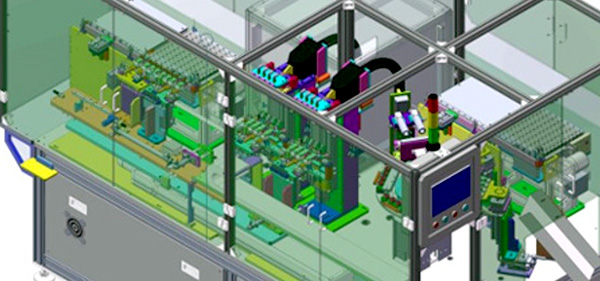

Related Products